Auxiliary testing fixture for detecting geometric parameters of steep-pitch thread

A technology of geometric parameters and large pitch, which is applied in measuring devices, mechanical measuring devices, mechanical diameter measurement, etc., can solve the problems that the middle diameter and large diameter of large pitch threads cannot be measured, and achieve wide use value, high measurement accuracy, The effect of expanding the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

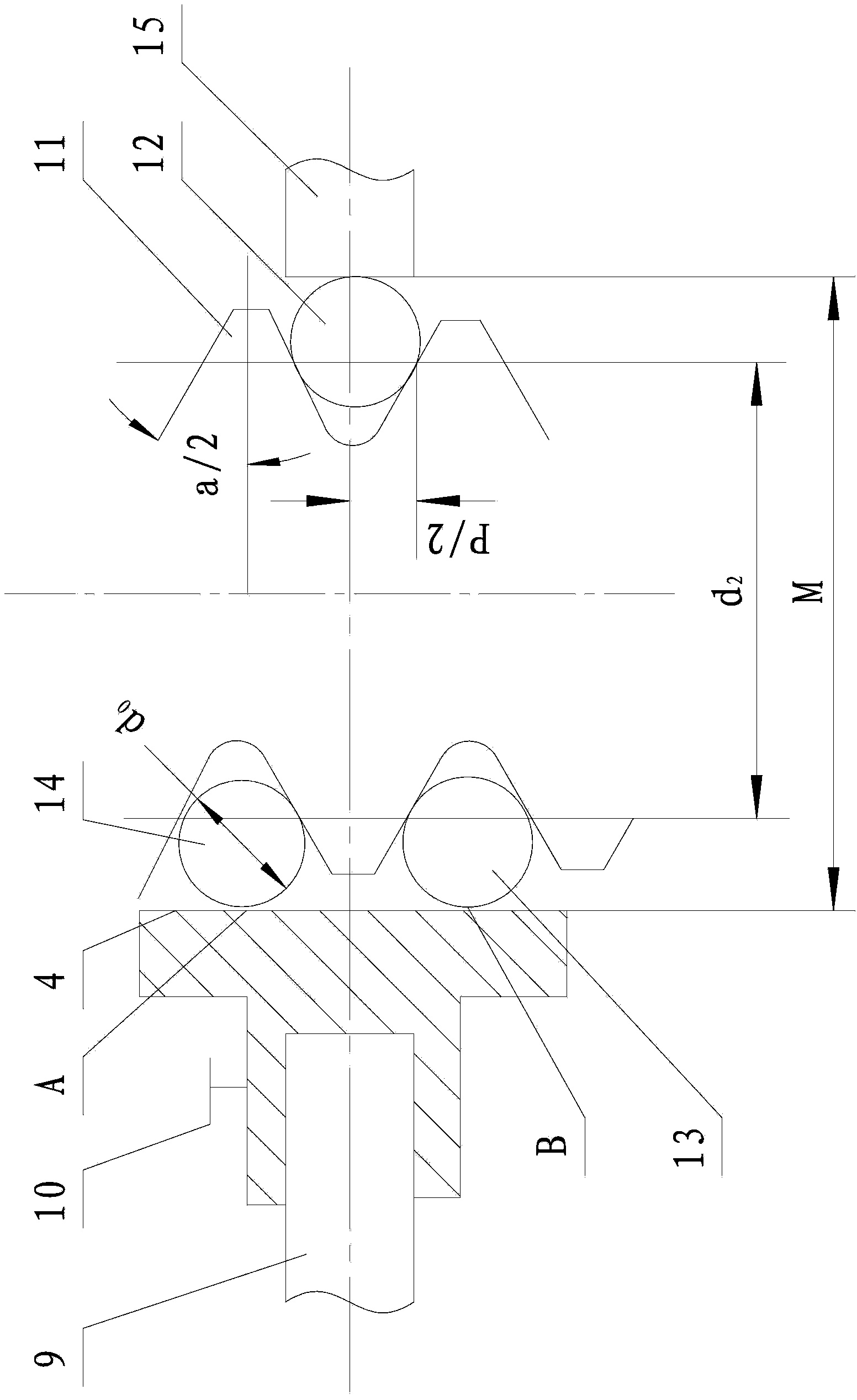

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

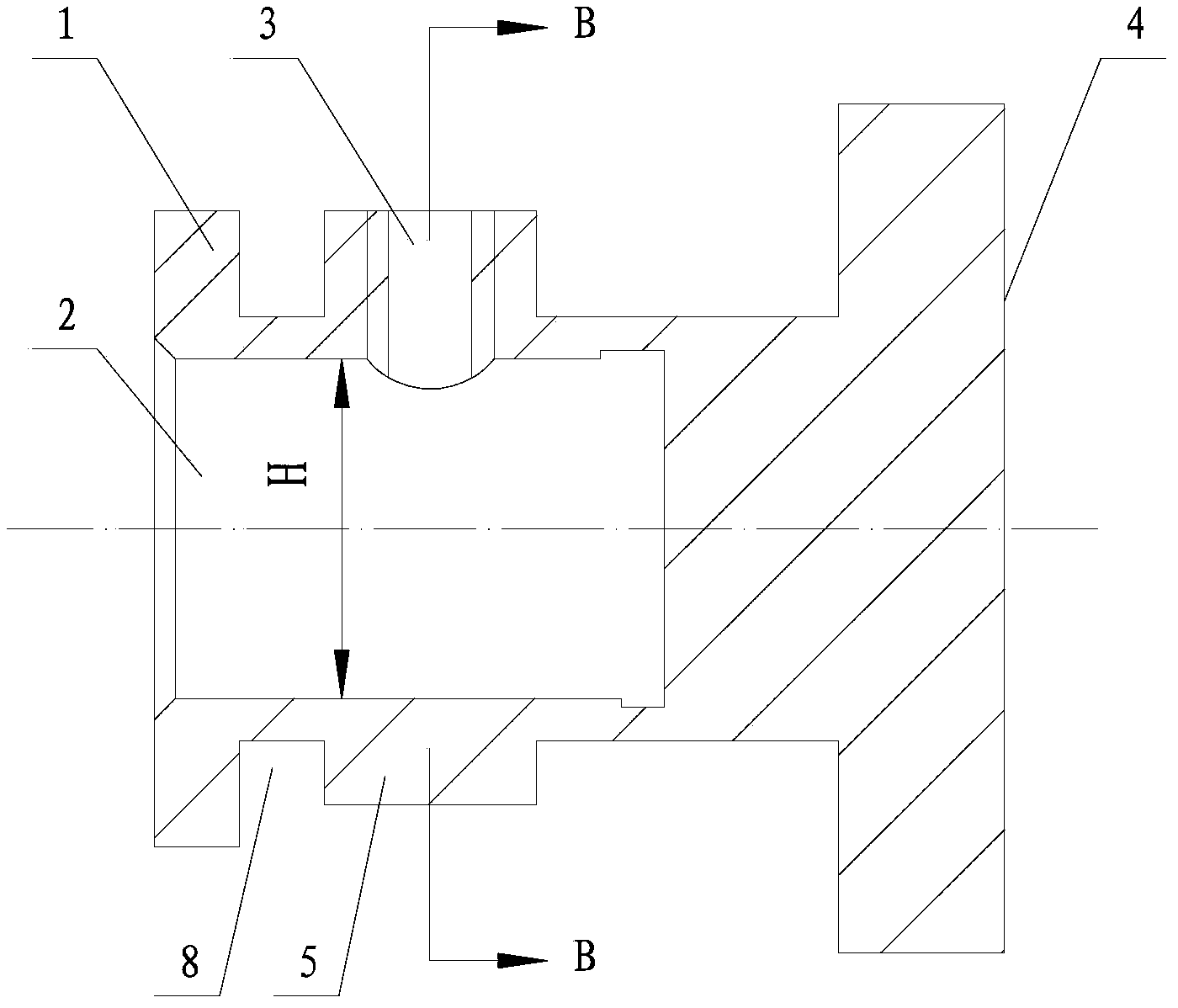

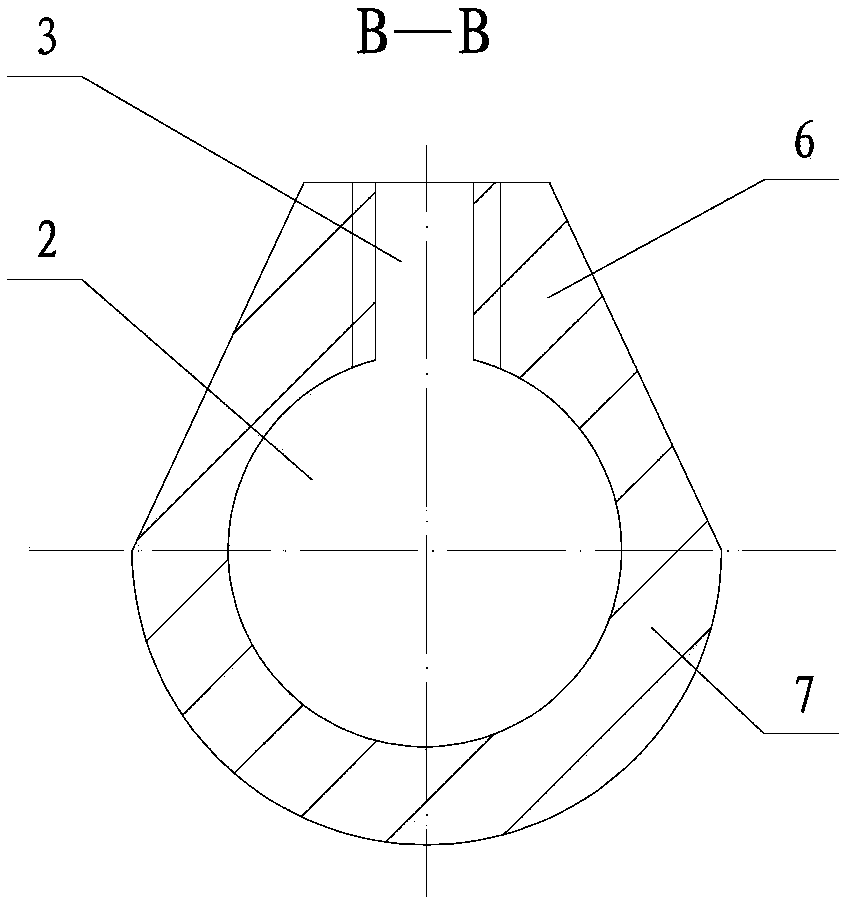

[0019] like figure 1 , figure 2 As shown, the auxiliary checking tool of the present invention is similar to a shaft sleeve. One end of the main body 1 of the checking tool is provided with a positioning hole 2 , and the end surface of the other end is a contact surface 4 .

[0020] The positioning hole 2 is a blind hole, and the size of the blind hole is the same as the outer diameter of the micrometer micrometer rod 9 of the outer diameter micrometer; on the main body 1 of the inspection tool above the positioning hole 2 axially, there is a micrometer rod 9 for fastening The threaded hole 3 communicates with the positioning hole 2. In this embodiment, a fastening part 5 is provided between the two ends of the main body 1 of the inspection tool. The fastening part 5 is divided into an upper part 6 and a lower part 7. In order to achieve a better fastenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com