A Method for Evaluating the Base Film Effect of Different Temperatures in Ceramic Coated Separators

A technology of ceramic coating and diaphragm, applied in the field of analysis, can solve the problem that the base film cannot be evaluated, and achieve the effect of non-destructive and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

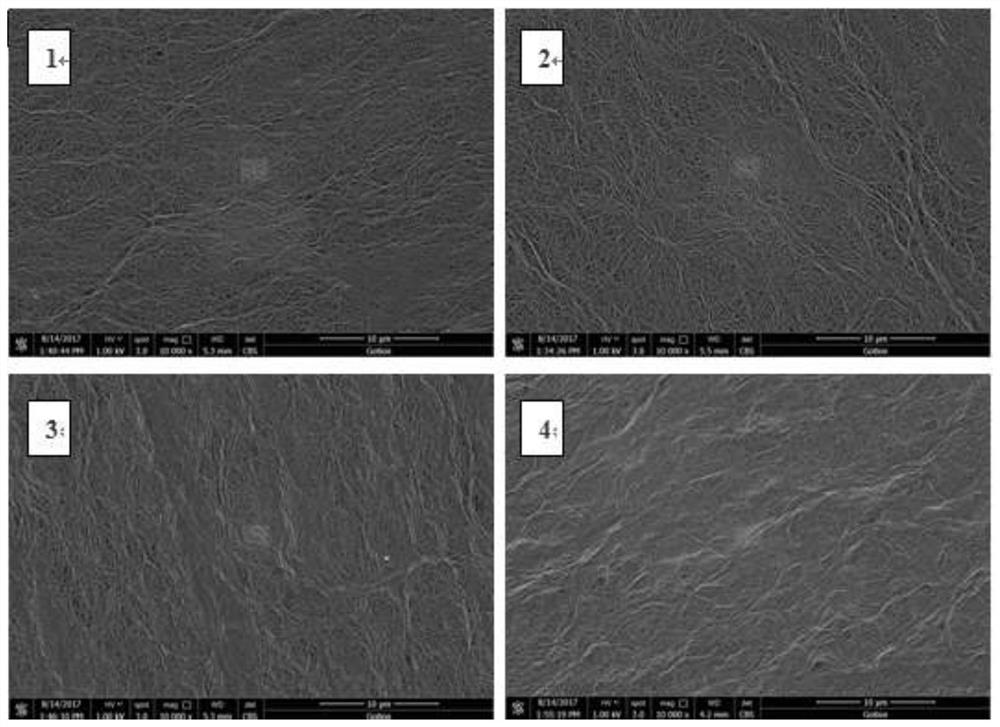

Image

Examples

Embodiment 1

[0017] A method for evaluating the effect of different temperatures on a base film in a ceramic coated separator comprising the steps of:

[0018] S1. Use alcohol to wipe the surface of the ceramic-coated diaphragm to be tested until the base film is exposed to obtain the diaphragm a;

[0019] S2. Divide the diaphragm a into a control group and at least one experimental group, then raise the temperature of the experimental group to 120-140° C., and keep it warm for 0.8-1.2 hours to obtain the diaphragm b;

[0020] S3. Weigh the diaphragm b, calculate its area, and calculate the basis weight of the basement membrane;

[0021] S4. Making the diaphragm b into a sample to be tested, spraying gold, placing it in the sample chamber of a scanning electron microscope, and photographing the morphology of the base film to determine the state of the base film of the ceramic-coated diaphragm to be tested at different temperatures.

Embodiment 2

[0023] A method for evaluating the effect of different temperatures on a base film in a ceramic coated separator comprising the steps of:

[0024] S1. Wipe the surface of the ceramic-coated diaphragm to be tested with a solvent until the base film is exposed to obtain a diaphragm a;

[0025] S2. Divide the diaphragm a into a control group and three experimental groups, and then raise the temperature of the experimental groups to 120°C, 130°C and 140°C respectively, keep it warm for 1 hour, and leave the control group untreated to obtain the diaphragm b;

[0026] S3. Weigh the diaphragm b, calculate its area, and calculate the basis weight of the basement membrane, as shown in the table below;

[0027] group Heating temperature, ℃ Basement membrane mass, g Basement membrane area, cm 2

Basement film surface density, g / m 2

control group room temperature 9.42×10 -2

131.50 7.16 Experimental group 1 120 9.39×10 -2

130.25 7.21 E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com