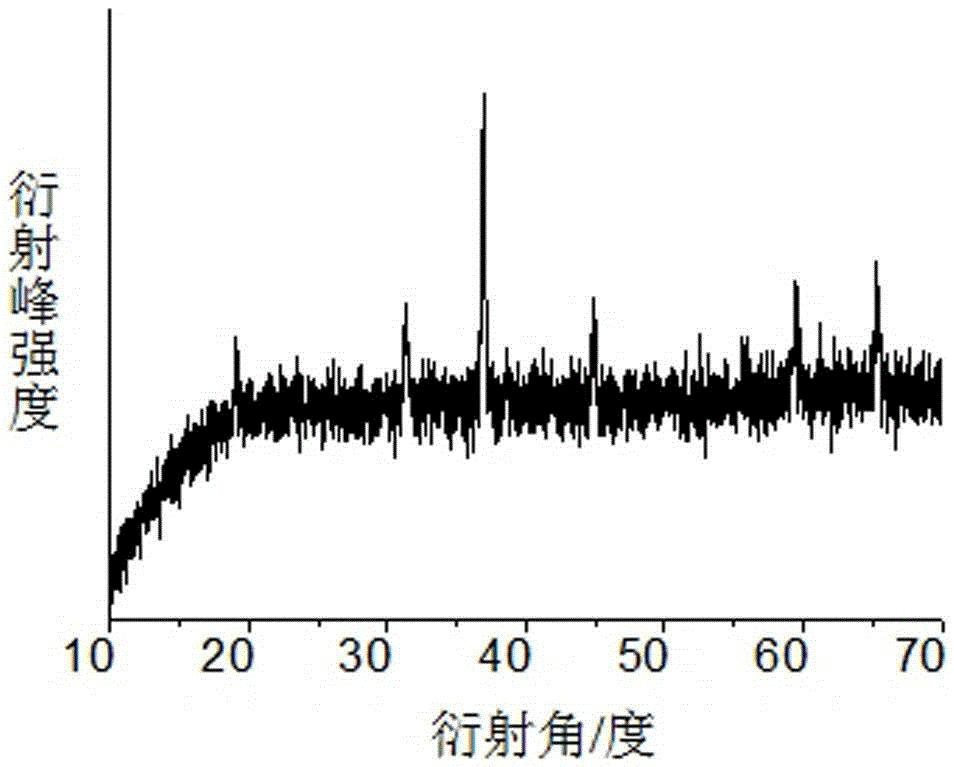

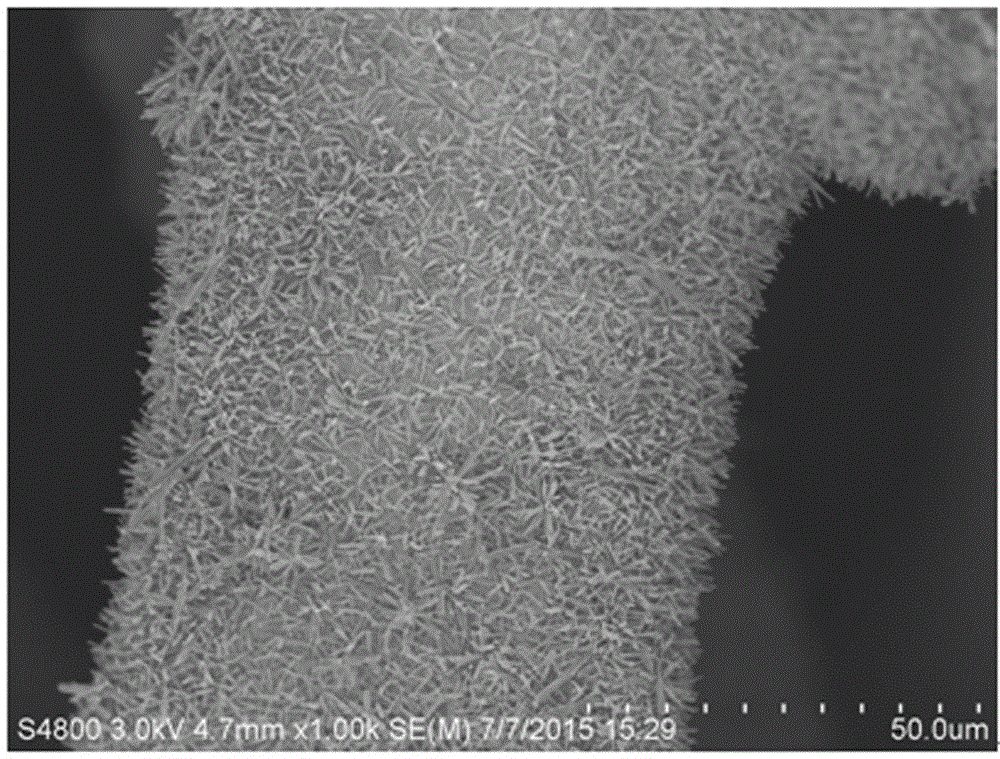

Preparation method of magnesium cobaltate porous micro-rod/ foamed nickel combined electrode material

A composite electrode and nickel foam technology, which is applied in the field of preparation of inorganic non-metallic materials, can solve the problems of low energy density and limited application, and achieve the effect of increasing active surface, improving utilization rate and enriching voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

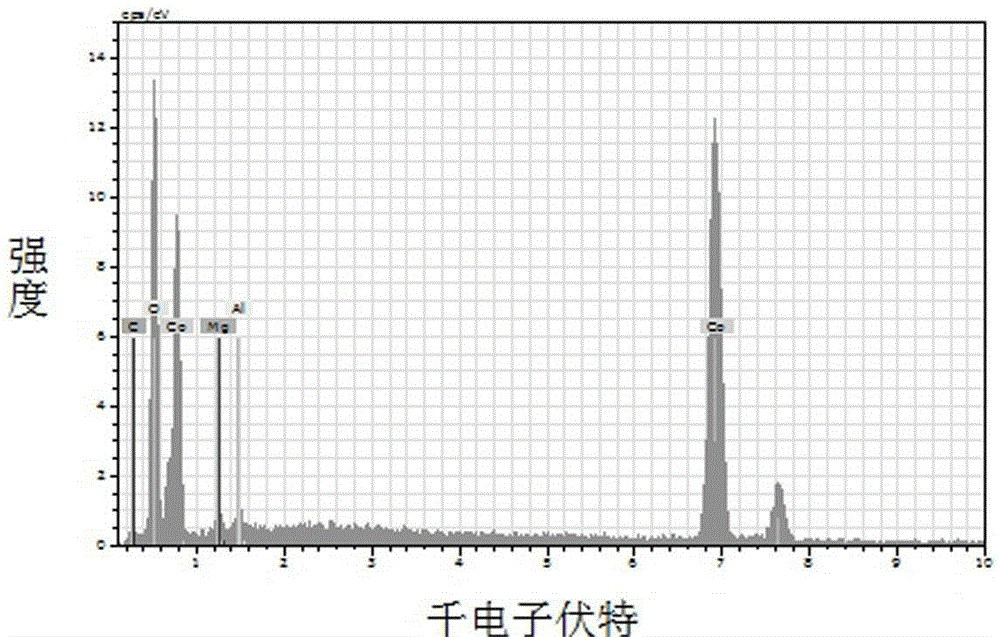

Embodiment 1

[0036] Immerse the clean nickel foam into 1.5mol / L oxalic acid aqueous solution, and add the mixed aqueous solution of magnesium nitrate and cobalt nitrate dropwise to the oxalic acid aqueous solution under the condition of the temperature of 25°C and the stirring speed of 100 rpm, in which the nitric acid The molar concentration of magnesium is 0.25mol / L, the molar concentration of cobalt nitrate is 0.5mol / L, the dropping rate is 120 drops / min, and the final molar ratio of magnesium nitrate and oxalic acid is 1:30. The stirring reaction time was 15 minutes. After the reaction, the nickel foam was taken out and washed, then put into an oven with a programmed temperature increase rate of 5°C / min, and dried at 100°C for 2 hours. Then put it in a muffle furnace for calcination, the calcination time is 2.5 hours, the calcination temperature is 350° C., and the heating rate is 10° C. / minute. After natural cooling, the magnesium cobaltate porous microrod / foam nickel composite elect...

Embodiment 2

[0039] Immerse the clean nickel foam into 1.0mol / L oxalic acid aqueous solution, and add the mixed aqueous solution of magnesium nitrate and cobalt nitrate dropwise to the oxalic acid aqueous solution under the condition of temperature of 25°C and stirring speed of 100 rpm, in which nitric acid The molar concentration of magnesium is 0.25mol / L, the molar concentration of cobalt nitrate is 0.5mol / L, the dropping rate is 100 drops / min, and the final molar ratio of magnesium nitrate and oxalic acid is 1:20. The stirring reaction time was 20 minutes. After the reaction, the nickel foam was taken out and washed, then put into an oven with a programmed temperature increase rate of 5°C / min, and dried at 100°C for 2 hours. Then put it in a muffle furnace for calcination, the calcination time is 2.0 hours, the calcination temperature is 350° C., and the heating rate is 10° C. / min. After natural cooling, the magnesium cobaltate porous microrod / foam nickel composite electrode material i...

Embodiment 3

[0042] Immerse the clean nickel foam into 1.5mol / L oxalic acid aqueous solution, and add the mixed aqueous solution of magnesium chloride and cobalt chloride dropwise to the oxalic acid aqueous solution under the condition of temperature of 25°C and stirring speed of 100 rpm, in which magnesium chloride The molar concentration is 0.25mol / L, wherein the cobalt chloride molar concentration is 0.5mol / L, the dropping rate is 120 drops / min, and the final molar ratio of magnesium chloride and oxalic acid is 1:20. The stirring reaction time was 10 minutes. After the reaction, the nickel foam was taken out and washed, then put into an oven with a programmed temperature increase rate of 5°C / min, and dried at 100°C for 2 hours. Then put it in a muffle furnace for calcination, the calcination time is 2.5 hours, the calcination temperature is 350° C., and the heating rate is 10° C. / minute. After natural cooling, the magnesium cobaltate porous microrod / foam nickel composite electrode mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molar concentration | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com