A kind of preparation method of copper cobalt oxide porous microrod/nickel foam composite electrode material

A composite electrode, nickel foam technology, applied in the field of preparation of inorganic non-metallic materials, can solve the problems of high price, low porosity, hindering the commercialization progress of RuO2, etc., to improve utilization, increase electrical conductivity, and excellent electrochemical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

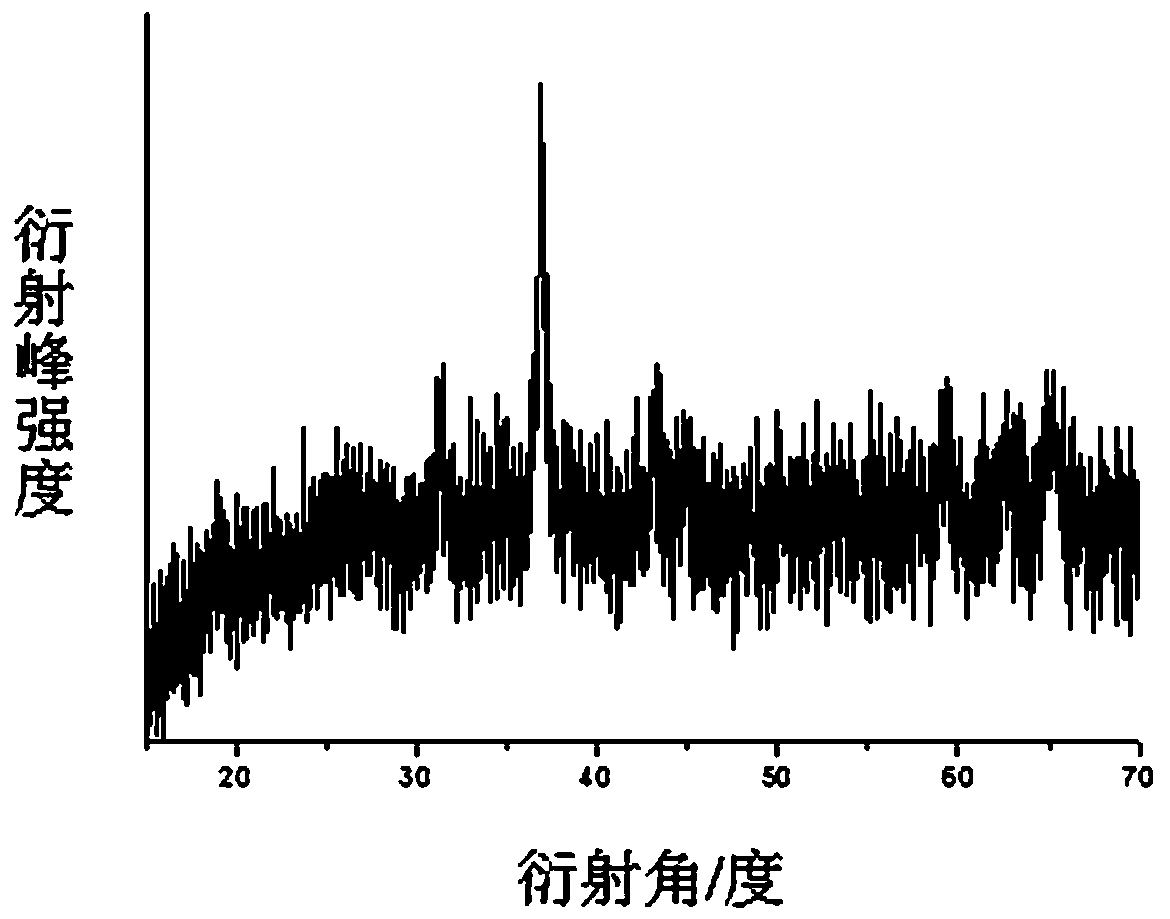

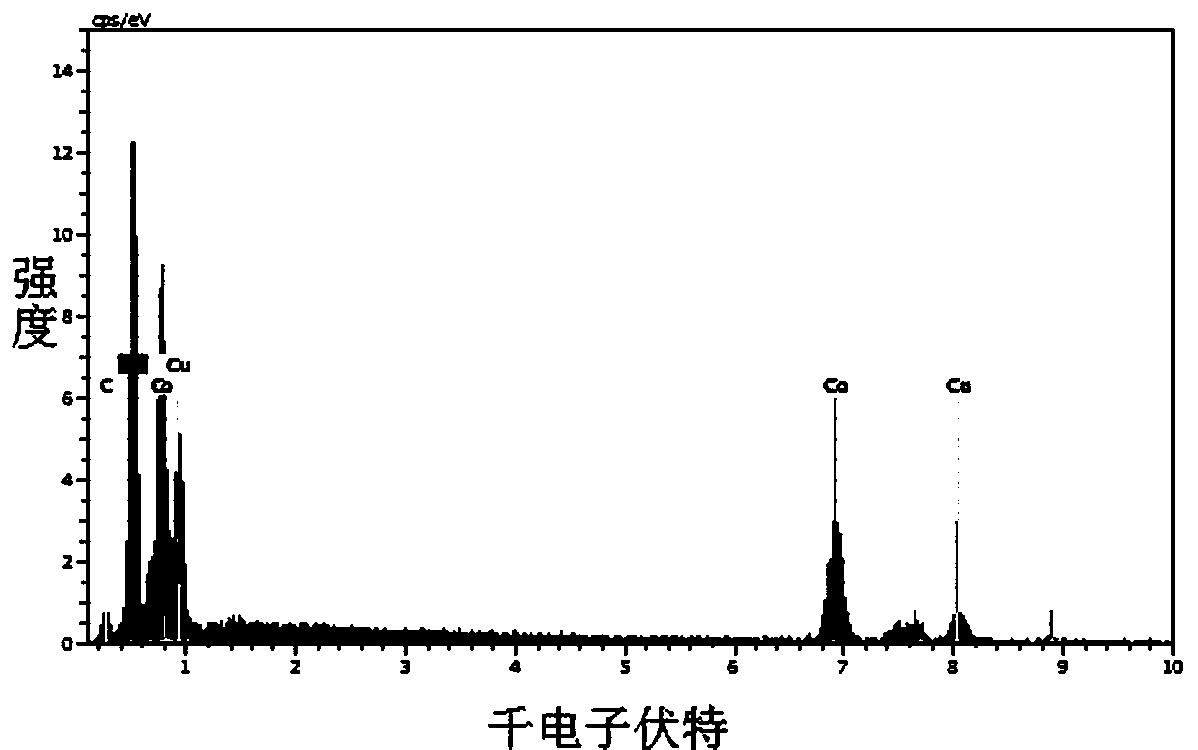

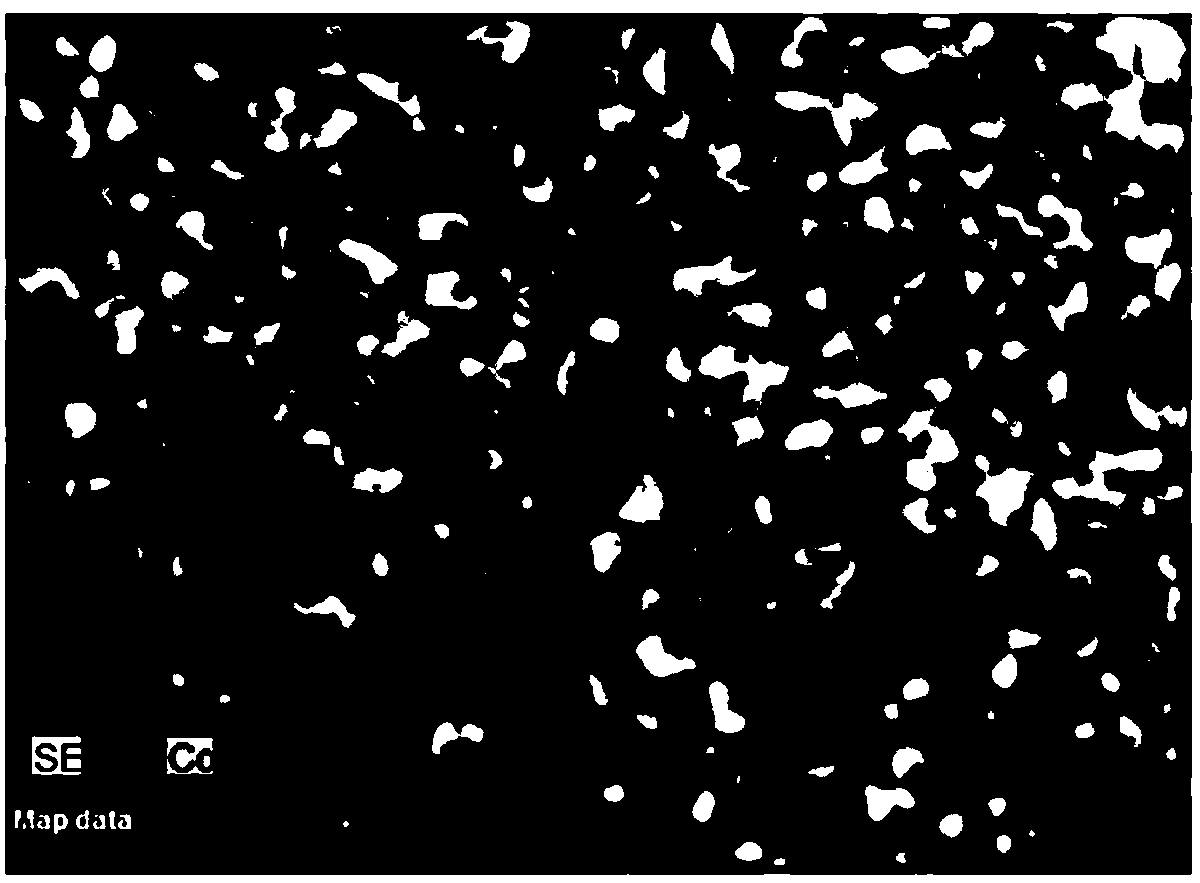

[0038]Immerse the clean nickel foam into 1.5 mol / L oxalic acid aqueous solution, and add the mixed aqueous solution of copper nitrate and cobalt nitrate dropwise to the oxalic acid aqueous solution at a temperature of 25 °C and a stirring speed of 100 rpm. The molar concentration of copper was 0.25 mol / L, the molar concentration of cobalt nitrate was 0.5 mol / L, the dropping rate was 120 drops / min, and the final molar ratio of copper nitrate and oxalic acid was 1:30. The stirring reaction time was 20 minutes. After the reaction, the nickel foam was taken out and washed, then put into an oven with a programmed temperature rise rate of 5 °C / min, and dried at 100 °C for 2 hours. Then place it in a muffle furnace for calcination, the calcination time is 2.5 hours, the calcination temperature is 350°C, and the heating rate is 10°C / min. After natural cooling, the copper cobaltate porous microrod / foam nickel composite electrode material is obtained.

[0039] In terms of mass percent...

Embodiment 2

[0041] Immerse the clean nickel foam into 1.0 mol / L oxalic acid aqueous solution, and add the mixed aqueous solution of copper nitrate and cobalt nitrate dropwise to the oxalic acid aqueous solution at a temperature of 25 °C and a stirring speed of 120 rpm, in which the nitric acid The molar concentration of copper was 0.25 mol / L, the molar concentration of cobalt nitrate was 0.5 mol / L, the dropping rate was 120 drops / min, and the final molar ratio of copper nitrate and oxalic acid was 1:30. The stirring reaction time was 20 minutes. After the reaction, the nickel foam was taken out and washed, then put into an oven with a programmed temperature rise rate of 5 °C / min, and dried at 100 °C for 2 hours. Then place it in a muffle furnace for calcination, the calcination time is 2.5 hours, the calcination temperature is 350°C, and the heating rate is 10°C / min. After natural cooling, the copper cobaltate porous microrod / foam nickel composite electrode material is obtained.

[0042...

Embodiment 3

[0044] Immerse the clean nickel foam into 1.5 mol / L oxalic acid aqueous solution, and add the mixed aqueous solution of copper nitrate and cobalt nitrate dropwise to the oxalic acid aqueous solution at a temperature of 25 °C and a stirring speed of 100 rpm. The molar concentration of copper is 0.25 mol / L, wherein the molar concentration of cobalt nitrate is 0.5 mol / L, the dropping rate is 120 drops / min, and the final molar ratio of copper nitrate and oxalic acid is 1:10. The stirring reaction time was 15 minutes. After the reaction, the nickel foam was taken out and washed, then put into an oven with a programmed temperature rise rate of 5 °C / min, and dried at 100 °C for 2 hours. Then place it in a muffle furnace for calcination, the calcination time is 2.5 hours, the calcination temperature is 350°C, and the heating rate is 10°C / min. After natural cooling, the copper cobaltate porous microrod / foam nickel composite electrode material is obtained.

[0045] In terms of mass pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com