A preparation method of nickel cobaltate/nickel tungstate/polyaniline ternary composite nanowire array electrode

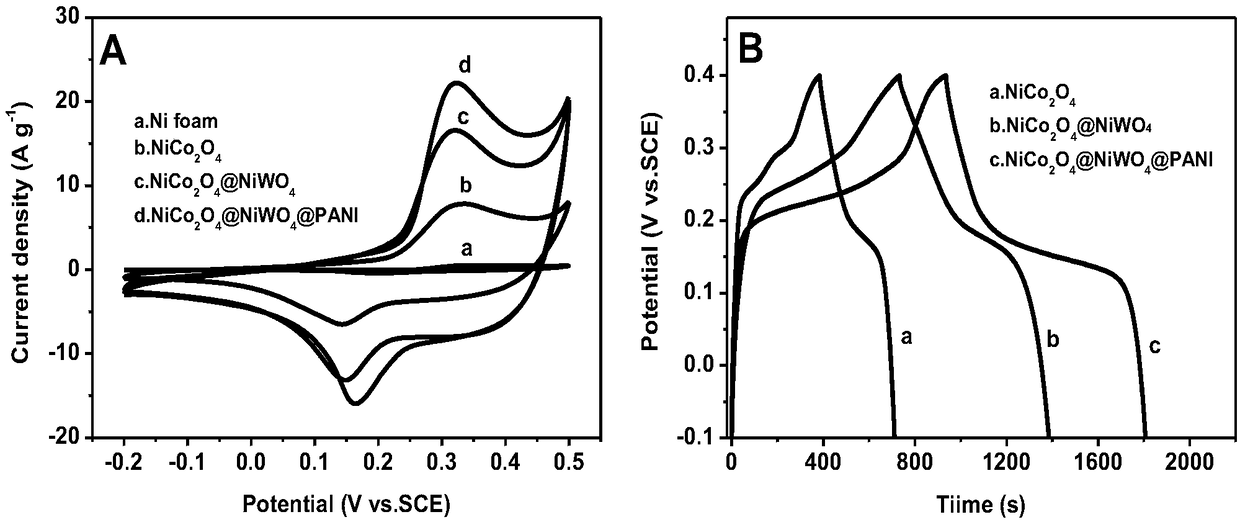

A nanowire array, ternary composite technology, applied in the direction of hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, etc., can solve the problem of overall electrochemical performance decline, improve diffusion mass transfer performance, increase active surface The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

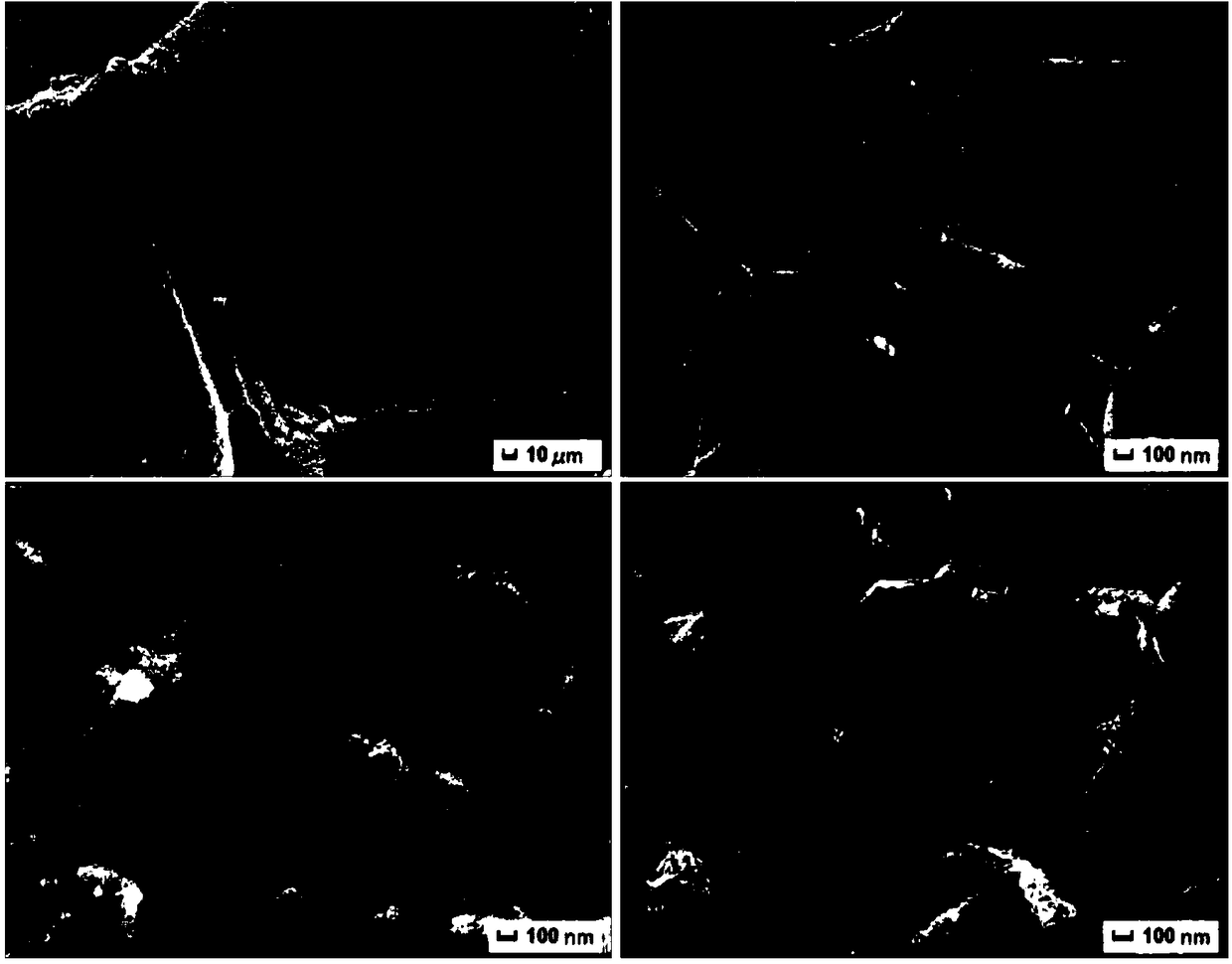

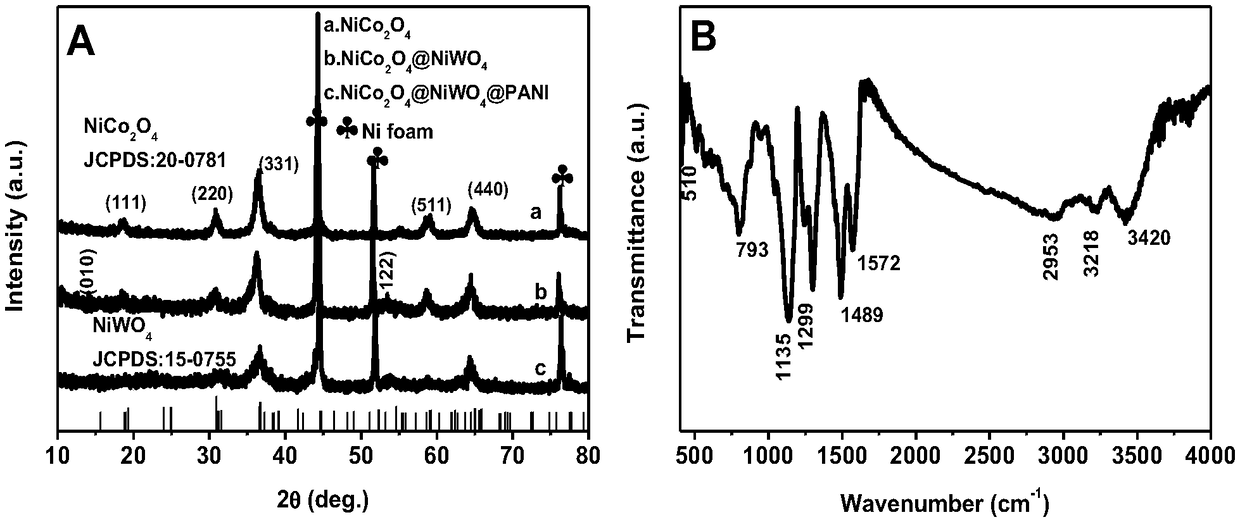

[0021] Accurately weigh 1mmol nickel nitrate, 2mmol cobalt nitrate and 8mmol urea, dissolve in 40mL deionized water and stir until clear, then transfer to a 50mL hydrothermal reactor, and put a piece of treated foamed nickel, seal and react at 130℃ 6h. After natural cooling, the foamed nickel was taken out, washed alternately with absolute ethanol and deionized water for 3 times, vacuum dried at 60°C for 12 hours, and finally calcined at 350°C for 2 hours to obtain a nickel cobaltate nanowire array.

[0022] Accurately weigh 1mmol of nickel nitrate, 1mmol of sodium tungstate and 6mmol of urea, dissolve in 40mL of deionized water and stir until they are evenly mixed, then transfer the mixed solution into a 50mL PTFE-lined stainless steel hydrothermal reactor, and get the result The nickel cobaltate nanowire array foam nickel substrate was put into it, and the reaction was kept at 130°C for 6h after sealing. After cooling to room temperature, the nickel foam was taken out, washed ...

Embodiment 2

[0026] Accurately weigh 1mmol nickel nitrate, 2mmol cobalt nitrate and 8mmol urea, dissolve in 40mL deionized water and stir until clear, then transfer to a 50mL hydrothermal reactor, and put in a piece of treated foamed nickel, seal and react at 110℃ 4h. After natural cooling, the nickel foam was taken out, washed with anhydrous ethanol and deionized water alternately 3 times, vacuum dried at 60°C for 12h, and finally calcined at 400°C for 2h to obtain a nickel cobaltate nanowire array.

[0027] Accurately weigh 1mmol of nickel nitrate, 1mmol of sodium tungstate and 6mmol of urea, dissolve in 40mL of deionized water and stir until they are evenly mixed, then transfer the mixed solution into a 50mL PTFE-lined stainless steel hydrothermal reactor, and get the result The nickel cobaltate nanowire array foam nickel substrate was put into it, and after sealing, it was reacted at 110°C for 4 hours. After cooling to room temperature, take out the foamed nickel, wash alternately with a...

Embodiment 3

[0030] Accurately weigh 1mmol nickel nitrate, 2mmol cobalt nitrate and 8mmol urea, dissolve in 40mL deionized water and stir until clear, then transfer to a 50mL hydrothermal reactor, and put a piece of treated foamed nickel, seal and react at 150℃ 8h. After natural cooling, the foamed nickel was taken out, washed alternately with absolute ethanol and deionized water for 3 times, vacuum dried at 60°C for 12 hours, and finally calcined at 350°C for 2 hours to obtain a nickel cobaltate nanowire array.

[0031] Accurately weigh 1mmol of nickel nitrate, 1mmol of sodium tungstate and 6mmol of urea, dissolve in 40mL of deionized water and stir until they are evenly mixed, then transfer the mixed solution into a 50mL PTFE-lined stainless steel hydrothermal reactor, and get the result The nickel cobaltate nanowire array foam nickel substrate was put into it, and the temperature was kept at 150°C for 8 hours after sealing. After cooling to room temperature, the nickel foam was taken out,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com