Cobalt nickel manganese lithium oxide-cooper oxide compound positive material for lithium ion battery and preparation method thereof

A composite cathode material, cobalt oxide nickel manganese lithium technology, used in battery electrodes, circuits, electrical components, etc., can solve the problems of poor cycle performance and poor repeatability, and achieve improved cycle life, small particle size, and good high rate performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, the cobalt nickel manganese oxide lithium-copper oxide composite positive electrode material for lithium ion batteries is prepared according to the following steps:

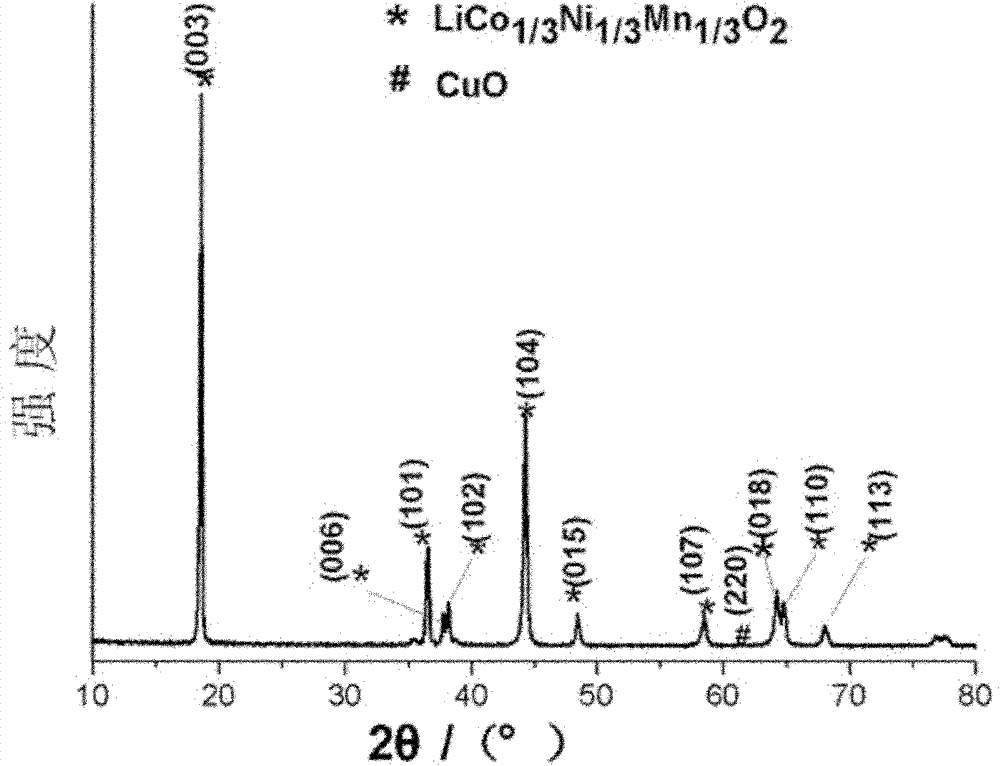

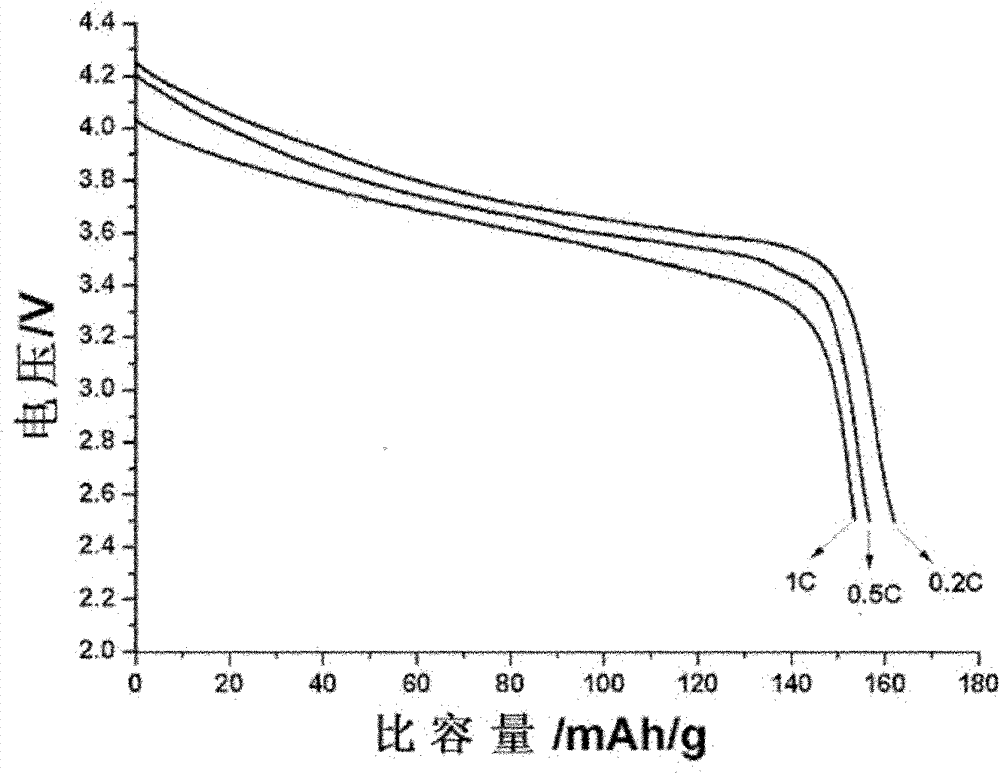

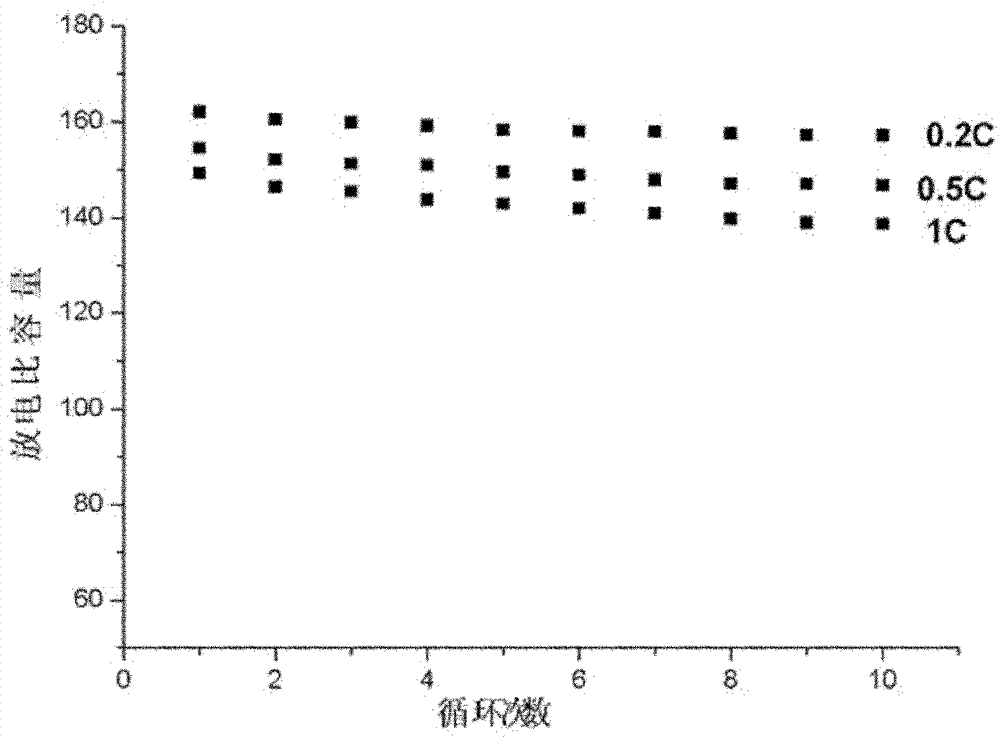

[0035]a. Weigh 1.471g NiO powder, 1.633g Co 2 o 3 powder and 1.713g MnO 2 powder, where in order to make up for Li at high temperature 2 CO 3 loss, making Li 2 CO 3 Excess 10%, weigh 2.399g Li 2 CO 3 Powder, add 10-20mL deionized water and put it into a mixing tank, put it into a planetary ball mill for 8 hours, take it out and dry it in an oven at 70°C for 12 hours, then put it in a crucible and put it in a box-type sintering furnace. In the air atmosphere, heat up to 300°C at a heating rate of 4°C / min, hold for 8 hours, then continue to heat up to 700°C, hold for 18 hours, then cool down to room temperature with the furnace, take out the sample and ball mill it again and pass it through a 400-mesh sieve to obtain a ternary product. Composite oxide lithium salt LiCo 1 / 3 Ni 1 / ...

Embodiment 2

[0040] In this embodiment, the cobalt nickel manganese oxide lithium-copper oxide composite positive electrode material for lithium ion batteries is prepared according to the following steps:

[0041] a. Weigh 1.411g NiO powder, 1.567g Co 2 o 3 powder and 1.643g MnO 2 Powder, wherein in order to make up for the loss of LiOH at high temperature, make LiOH excess 10%, weigh 2.616g LiOH powder, add 10-20mL deionized water and put it into a mixing tank, put it into a planetary ball mill for ball milling for 8 hours, take it out and put it in Dry in an oven at 90°C for 8 hours, then put it in a crucible and put it in a box-type sintering furnace, raise the temperature to 600°C at a rate of 4°C / min in an air atmosphere, keep it for 4 hours, then continue to heat up to 850°C, keep it 12 hours, then cool to room temperature with the furnace, take out the sample and ball mill again and pass through a 400 mesh sieve to obtain the ternary composite oxide lithium salt LiCo 1 / 3 Ni 1 / 3 ...

Embodiment 3

[0045] In this embodiment, the cobalt nickel manganese oxide lithium-copper oxide composite positive electrode material for lithium ion batteries is prepared according to the following steps:

[0046] a. Weigh 1.471g NiO powder, 1.633g Co 2 o 3 powder and 1.713g MnO 2 powder, where in order to make up for Li at high temperature 2 CO 3 loss, making Li 2 CO 3 Excess 10%, weigh 2.399g Li 2 CO 3 Powder, add 10-20mL deionized water and put it into the mixing tank, put it into a planetary ball mill for 8 hours, take it out and dry it in an oven at 80°C for 10 hours, then put it in a crucible and put it in a box-type sintering furnace. In the air atmosphere, heat up to 500°C at a heating rate of 4°C / min, hold for 6 hours, then continue to heat up to 750°C, hold for 16 hours, then cool to room temperature with the furnace, take out the sample and ball mill it again and pass it through a 400-mesh sieve to obtain a ternary product. Composite oxide lithium salt LiCo 1 / 3 Ni 1 / 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com