Preparation method and application of a chemical fluorescent sensing material

A technology of chemiluminescence and sensing materials, which is applied in the preparation of fluorescence-responsive materials and chemiluminescence sensing materials. It can solve the problems of biopolymer deactivation, rareness, and biological disorder, and achieve mild detection conditions. , fast response time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

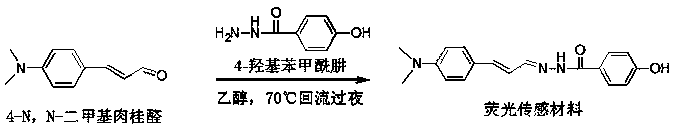

[0031] Synthesis of fluorescent sensing materials based on cinnamaldehyde derivatives: 0.17g of 4-N, N-dimethylcinnamaldehyde and 0.15g of 4-hydroxybenzoic hydrazide were placed in a 100mL round bottom flask, and 20 mL Dissolve the two in absolute ethanol, add 1 drop of glacial acetic acid dropwise, and place in an oil bath at 50 °C to stir and reflux for 5 h. After the reaction was completed, it was cooled to room temperature, and the solvent was removed under reduced pressure to obtain a crude product of the fluorescent sensing material. The crude product was purified by column chromatography (ethyl acetate:petroleum ether v / v=1:3) to obtain (0.255g) a pure yellow powder product. The yield was 82.6%.

Embodiment 2

[0033]Synthesis of fluorescent sensing materials based on cinnamaldehyde derivatives: 0.35g of 4-N, N-dimethylcinnamaldehyde and 0.31g of 4-hydroxybenzoic hydrazide were placed in a 100mL round bottom flask, and 40 mL Dissolve the two in absolute ethanol, add 2 drops of glacial acetic acid dropwise, and place in an oil bath at 65 °C to stir and reflux for 8 h. After the reaction was completed, it was cooled to room temperature, and the solvent was removed under reduced pressure to obtain a crude product of the fluorescent sensing material. The crude product was purified by column chromatography (ethyl acetate:petroleum ether v / v=1:3) to obtain (0. 558g) a pure yellow powder product. The yield was 90.3%.

Embodiment 3

[0035] Synthesis of fluorescent sensing materials based on cinnamaldehyde derivatives: 0.70 g of 4-N, N-dimethylcinnamaldehyde and 0.62 g of 4-hydroxybenzoic hydrazide were placed in a 100 mL round bottom flask, and 60 mL of Dissolve the two in absolute ethanol, add 3 drops of glacial acetic acid dropwise, and place in an oil bath at 75 °C to stir and reflux for 10 h. After the reaction was completed, it was cooled to room temperature, and the solvent was removed under reduced pressure to obtain a crude product of the fluorescent sensing material. The crude product was purified by column chromatography (ethyl acetate:petroleum ether v / v=1:3) to obtain (1.095g) a pure yellow powder product. The yield was 89.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com