Method for preparing modified micro-rods and reinforced plastic containing modified micro-rods

A technology of reinforced plastics and micron rods, which is applied in pulp beating/refining methods, fiber raw material treatment, acid acid/anhydride pulping, etc. It can solve the problems of low recycling rate, low utilization rate of straw, limited chemical methods, etc. problems, to achieve the effect of increasing utilization rate, maximizing utilization value and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The straw is reed straw (reed straw), crushed, washed and fully dried, and passed through a 60-mesh sieve. The ball milling speed of the ball mill jar was 300 rpm. The total mass of the ball is 65g.

[0035] The straw and maleic anhydride (MA) were added into the ball mill tank at a mass ratio of 1:3. The ball milling time is 0.5h.

Embodiment 2-6

[0037] Raw material and equipment are with embodiment 1. The difference is that the time of ball milling is 1, 2, 3, 4, 5 hours respectively.

[0038] Morphological observation

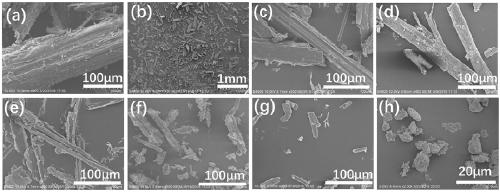

[0039] The scanning electron microscope picture of the modified straw fiber rod prepared by embodiment 1-6 is as follows figure 1 . Through microscopic observation, it is found that the morphology of cellulose can be maintained to a certain extent with maleic anhydride ball milling. and figure 1 Figure (h) does not have maleic anhydride, and the products all become particles. With the increase of ball milling time, the size of fiber rods gradually decreased.

[0040] Micro rods obtained by ball milling for 1 to 5 hours, see figure 1 From (c) to (g), it can be seen that the size is uniform, with a diameter of about 10 μm and a length of about 40 μm. Further zooming in, it can be seen that there is uniform and dense maleic anhydride on the surface of the straw.

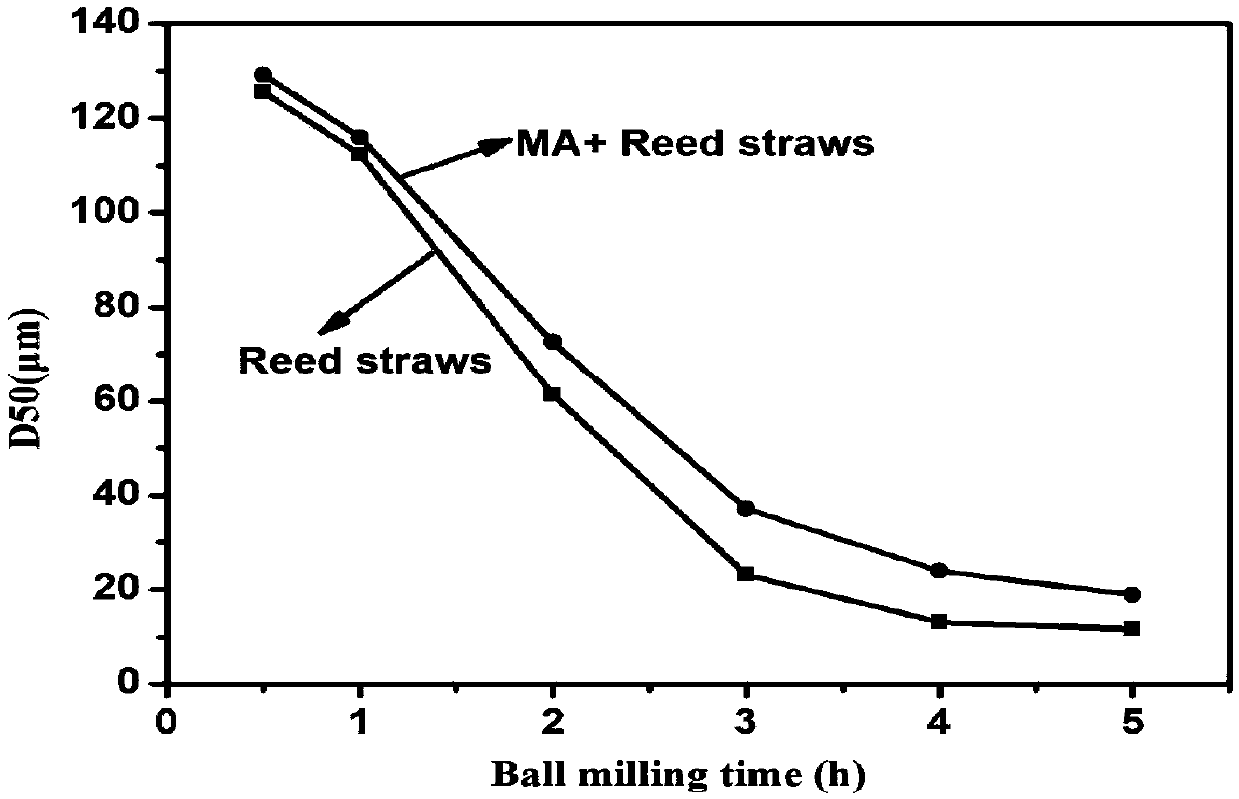

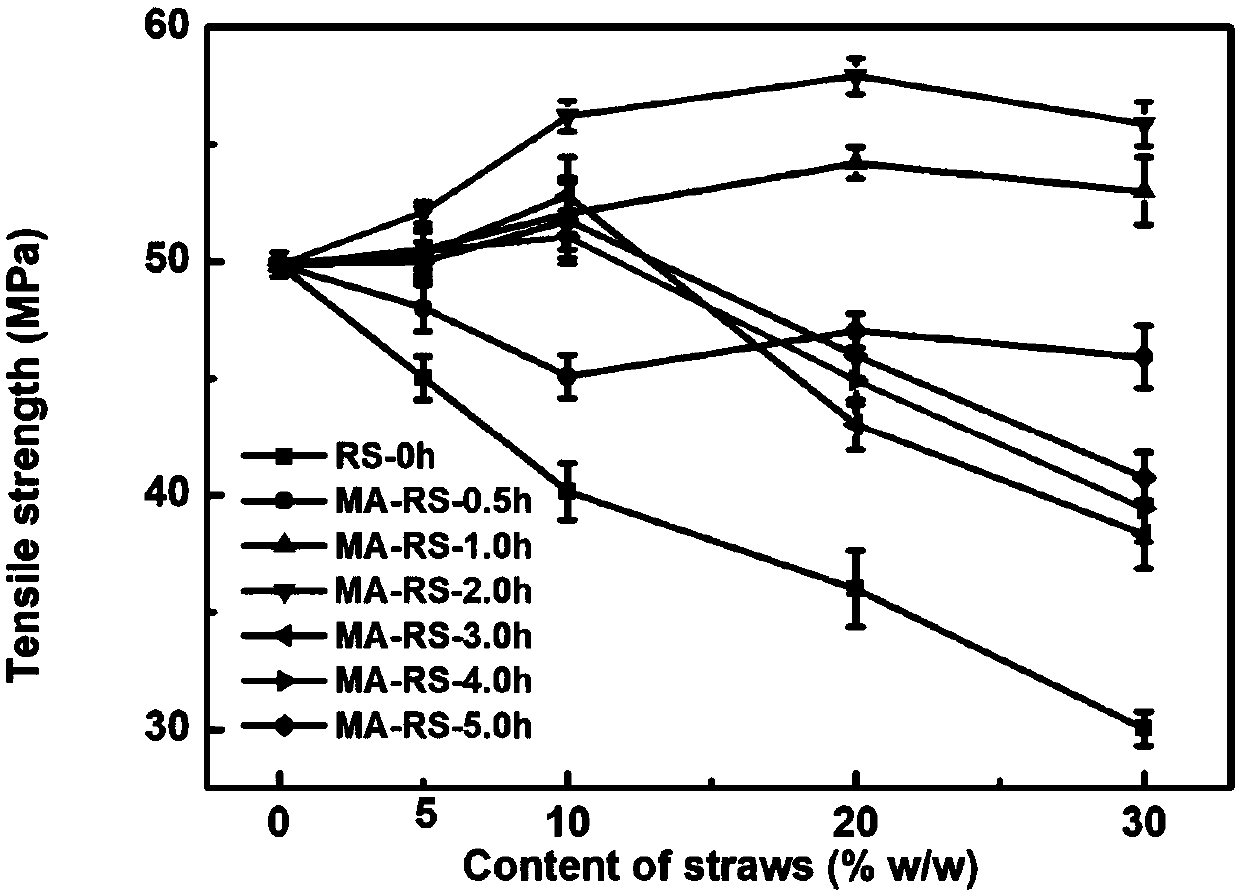

[0041] figure 2 After mixing m...

Embodiment 7

[0043] The straw is reed straw (reed straw), crushed, washed and fully dried, and passed through a 60-mesh sieve. The ball milling speed of the ball mill jar was 300 rpm. The total mass of the ball is 65g.

[0044] The straw and tartaric acid are added into the ball milling tank at a mass ratio of 1:3. The ball milling time is 2h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com