Li4Ti5O12, Li(4-a)ZaTi5O12 OR Li4ZbetaTi(5-beta)O12 particles, process for obtaining same and use as electrochemical generators

a technology of li4ti5o12 and li4a zati5o12, which is applied in the field of new particles, can solve the problems of limited structure and very slight sacrifice capacity of li4ti5o12, and achieve the effects of reducing the cost of production and maintenance, and improving the efficiency of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation in the Presence of Heptane of Particles of Li4T5O12 Coated with Carbon

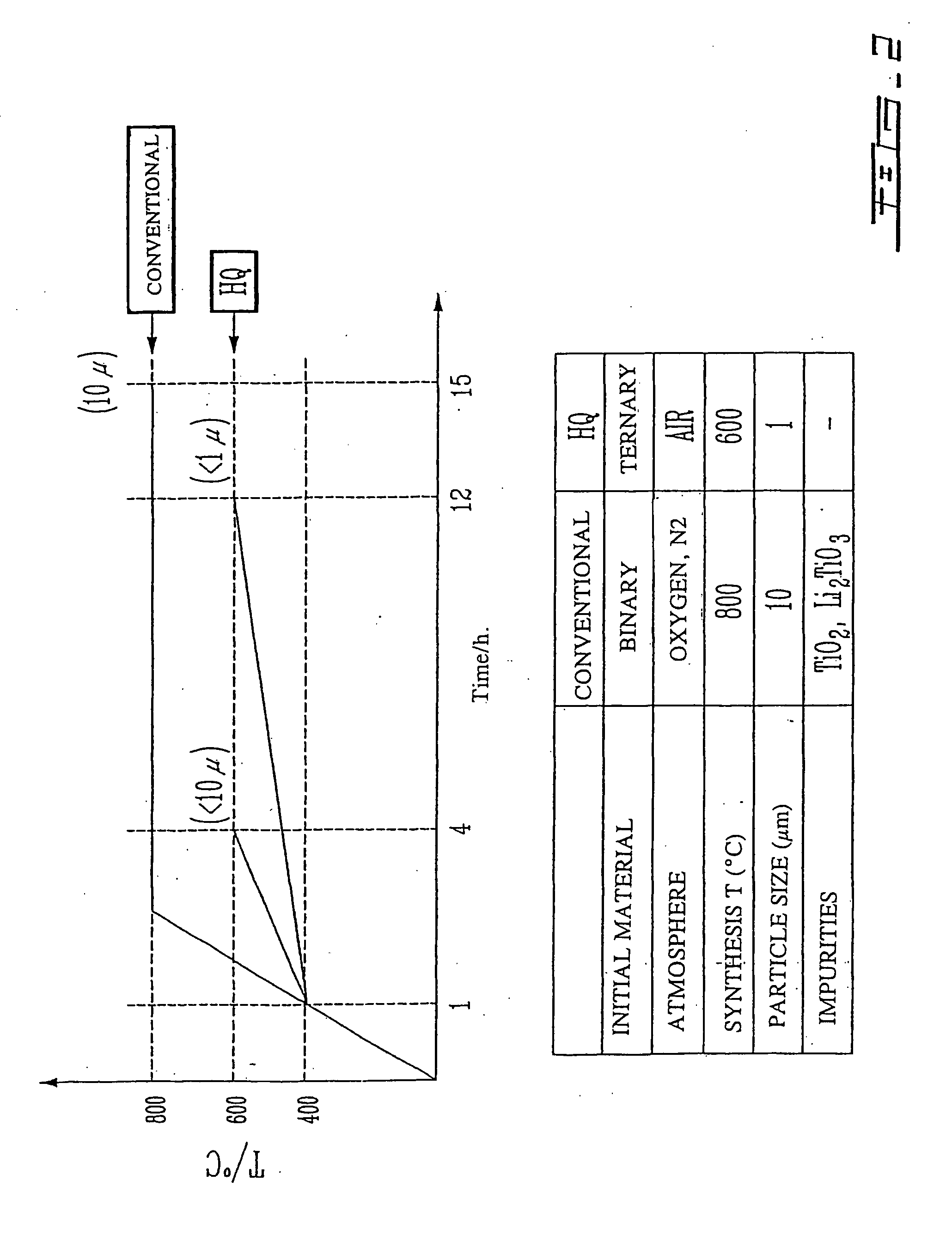

[0127] 23 g of TiO2 with anatase structure (commercialized by the Kronoss Company, Varennes, Canada under the name XP-406) are mixed with 10 grams of Li2CO3 (Aldrich, Canada) and with 20 grams of Shawinigan black. An excess of carbon black is used to ensure complete transformation of the CO2 and lower the synthesis temperature.

[0128] This ternary mixture is placed in a steel container and heptane is added in a powder / liquid ratio of around 35 g / 150 ml. The heptane is used to reduce the heat and the friction between the particles of powder and the balls and leaves the product inert. Stainless steel balls are added to homogenize the ternary mixture. After 2 hours of intimate co-milling, a powder with fine particle size is obtained. The success of the co-milling depends on lowering the synthesis temperature. The heating of this co-milled mixture is carried out in two steps. The first step is a rapid hea...

example 2

Dry Preparation of Particles of Li4Ti5O12 Coated with Carbon

[0129] 23 g of TiO2 with anatase structure (XP-406 from the Kronos Company, Varennes) are mixed with 10 grams of Li2CO3 (Aldrich, Canada) and with 20 g of Shawinigan black. Again an excess of carbon black is used to ensure complete transformation of the CO2 and lower the synthesis temperature. This ternary mixture is placed in a dry container with stainless steel balls.

[0130] After 2 hours of intimate milling, a powder with a fine particle size is obtained. Heating of this co-milled mixture is carried out in two steps, at 400° C. and then at 600° C. The X-ray spectrum reveals the presence of a spinel structure for the Li4Ti5O12 particles thus synthesized.

example 3

Dry Preparation and Characterization of Nano-Particles of Li4T5O12 Coated with Carbon

[0131] 23 g of TiO2 with anatase structure (XP-406 from the Kronos Company, Varennes) are mixed with 10 grams of Li2CO3 (Aldrich, Canada) and with 2 grams of Shawinigan black. A 6-gram excess of carbon black is again used to ensure complete transformation of the CO2 and to lower the synthesis temperature. This ternary mixture is subject to high-energy mechanical milling (using a shaker mill machine of the type SPEX 8000) in the presence of stainless steel balls in a ball:powder ratio of 10:1. The milling period can vary between 3 minutes and 3 hours, which in the case of the present example is 2 hours. Heating of the co-milled mixture is carried out in two steps. The first step consists of rapid heating to 400° C. in air. The second step consists of slow heating to 600° C. This completes the transformation of the product into Li4Ti5O12 with spinel structure. The X-ray spectrum confirms the presence...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com