Negative active material, method of preparing same, and rechargeable lithium battery including same

A negative electrode active material, lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low conductivity, high performance degradation, unusable batteries, etc., to achieve excellent charging and discharging characteristics, low expansion phenomenon , the effect of improving expansion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

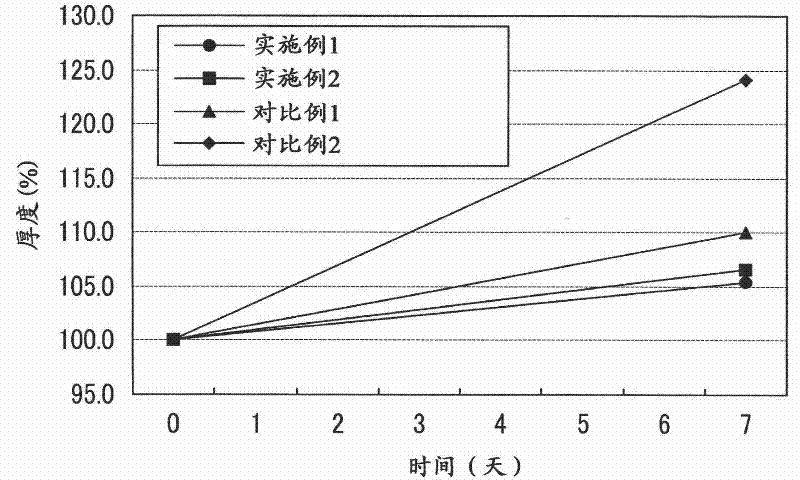

Embodiment 1

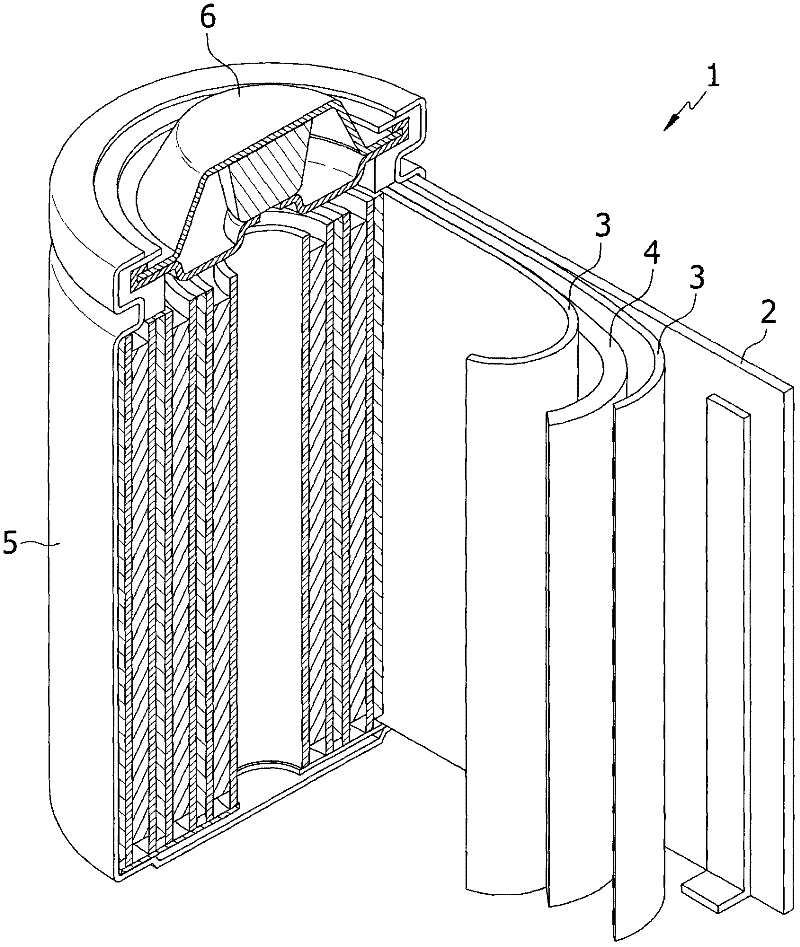

[0105] In a ball mill, the Li 2 CO 3 and TiO 2 Mix and stir in water to prepare a slurry including lithium-titanium composite fine particles. At this time, the average particle diameter of the lithium-titanium composite fine particles was about 1 μm.

[0106] The above slurry was sprayed and dried at about 300° C. to obtain large lithium-titanium composite particles. The obtained large lithium-titanium composite particles had an average particle diameter of about 50 μm.

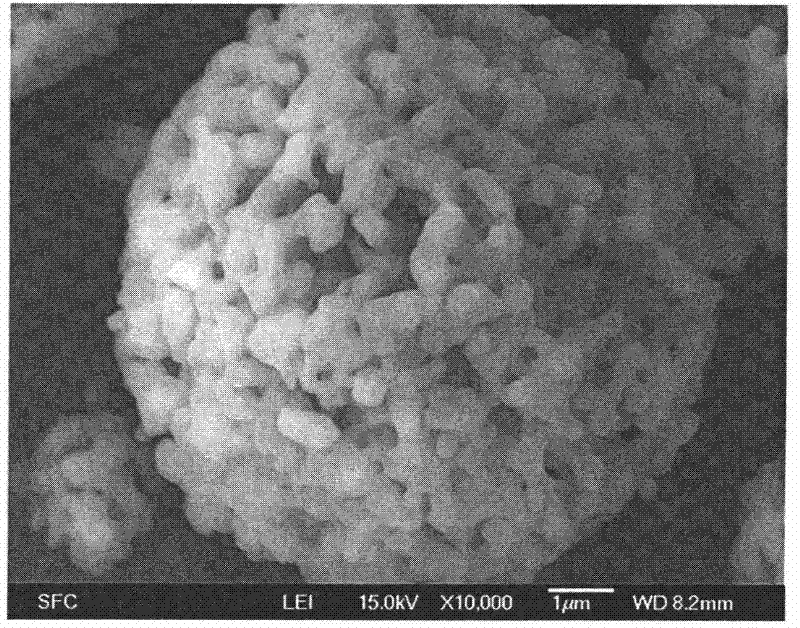

[0107] The resulting large particles were sintered in a sintering furnace for about 5 hours at a temperature of about 850° C. in an air atmosphere, and pulverized so that the primary particles of the sintered product had an average particle size of about 250 nm (existing between 100 nm and 500 nm) , and the secondary particles have an average particle size of about 20 μm. Therefore, if figure 2 As shown in the SEM photo of , a negative electrode active material including secondary particles was prepare...

Embodiment 2

[0112] Using a particle mill, the Li 4 Ti 5 o 12 The secondary particles obtained from the primary particles shown were pulverized so that the average particle diameter of the secondary particles became about 10 μm to prepare a negative electrode active material.

[0113] The negative active material has about 3.0m 2 / g specific surface area. The primary particles have an average particle diameter of about 250 nm (between 100 nm and 500 nm). Based on the total weight of the negative active material, the negative active material included 0.1 wt% of carbonate.

[0114] Using the above negative active material, a half cell was fabricated according to the same procedure as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com