Memory cell that includes a carbon-based memory element and methods of forming the same

a memory element and memory cell technology, applied in the field of nonvolatile memories, can solve problems such as delamination of carbon materials and degradation of switching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

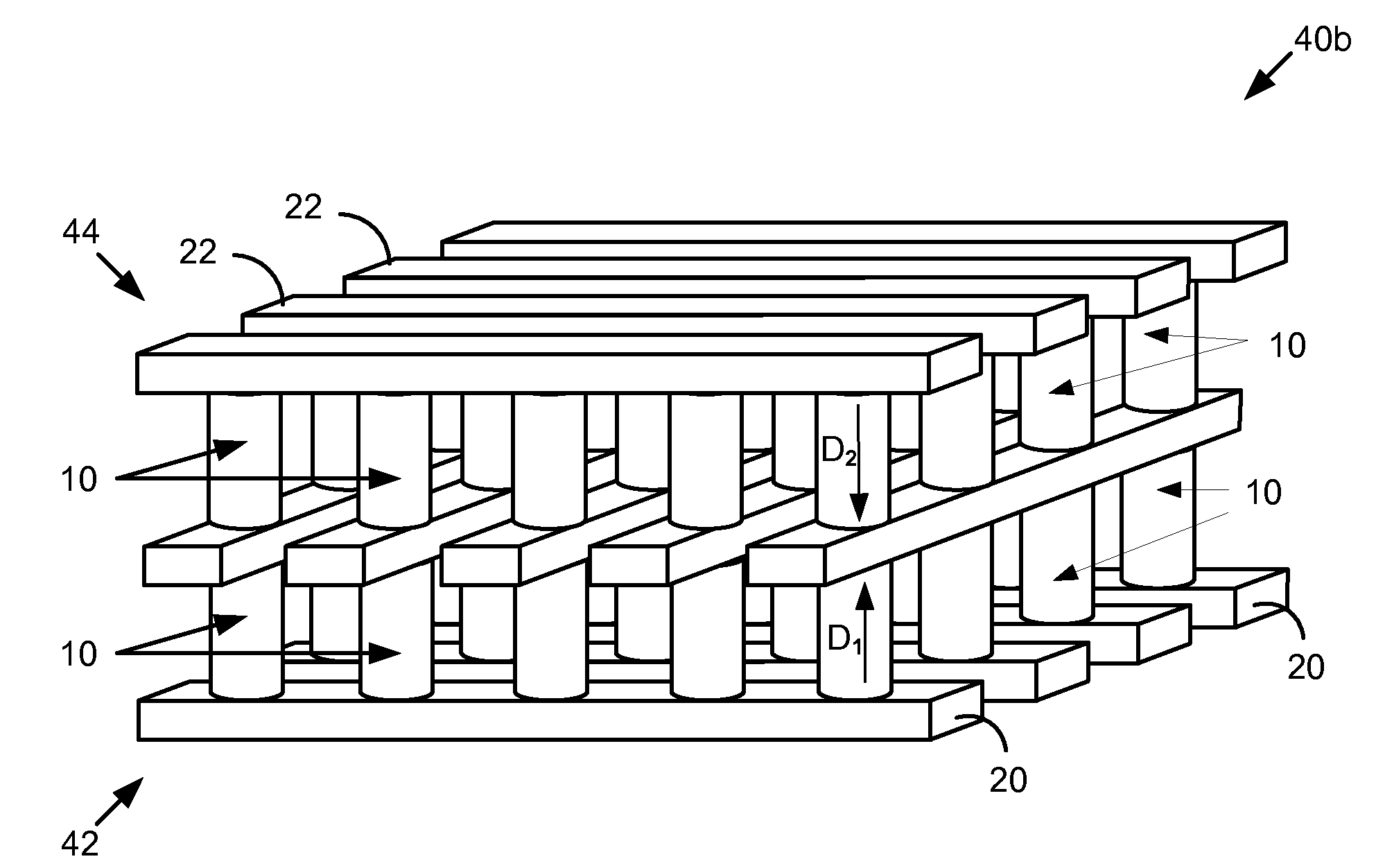

Embodiment Construction

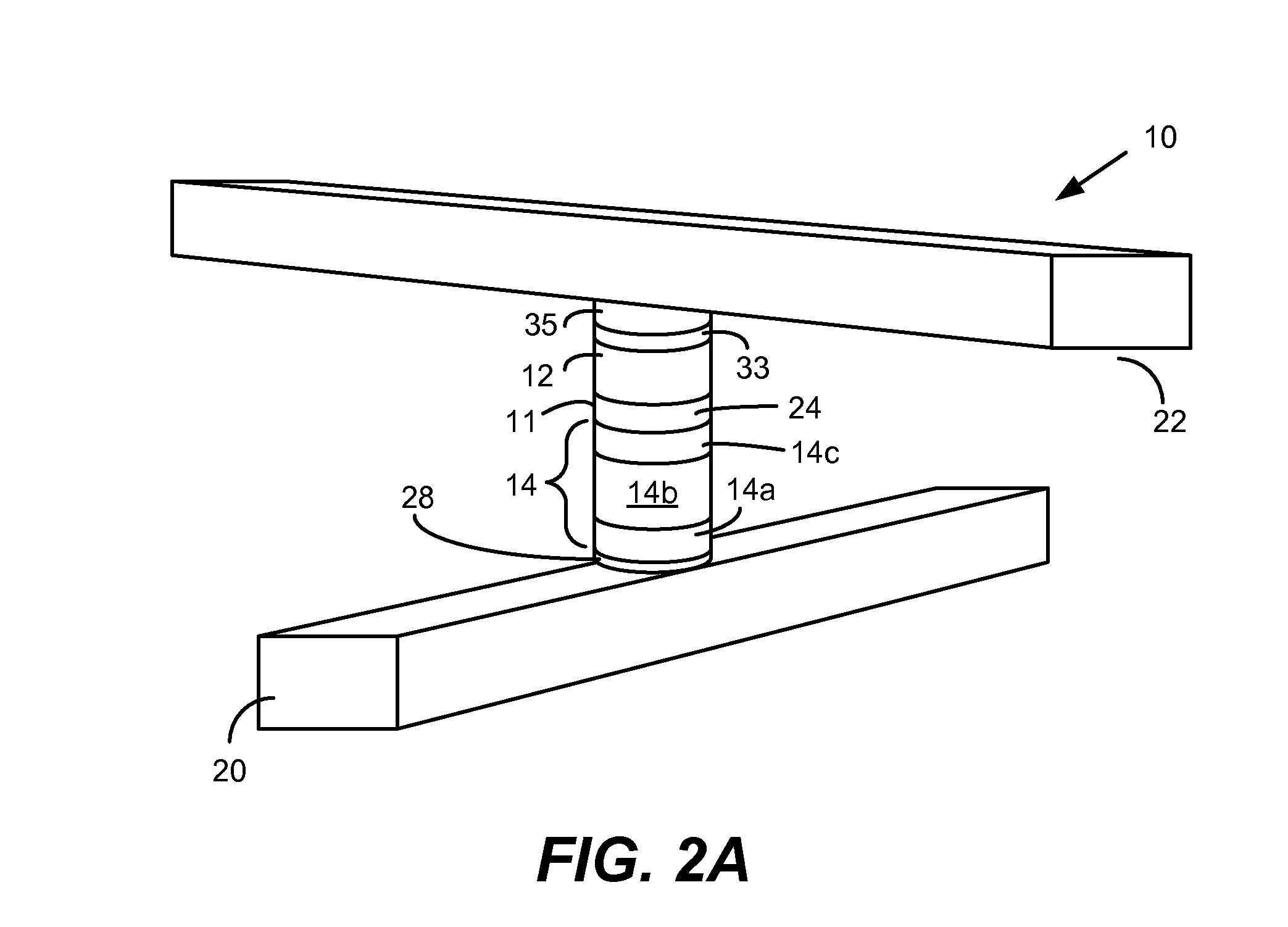

[0017]Carbon films such as amorphous carbon (“aC”) containing nanocrystalline graphene (referred to herein as “graphitic carbon”), graphene, graphite, carbon nano-tubes, amorphous diamond-like carbon (“DLC”) (described below), silicon carbide, boron carbide and other similar carbon-based materials may exhibit resistivity-switching behavior that may make such materials suitable for use in microelectronic non-volatile memories.

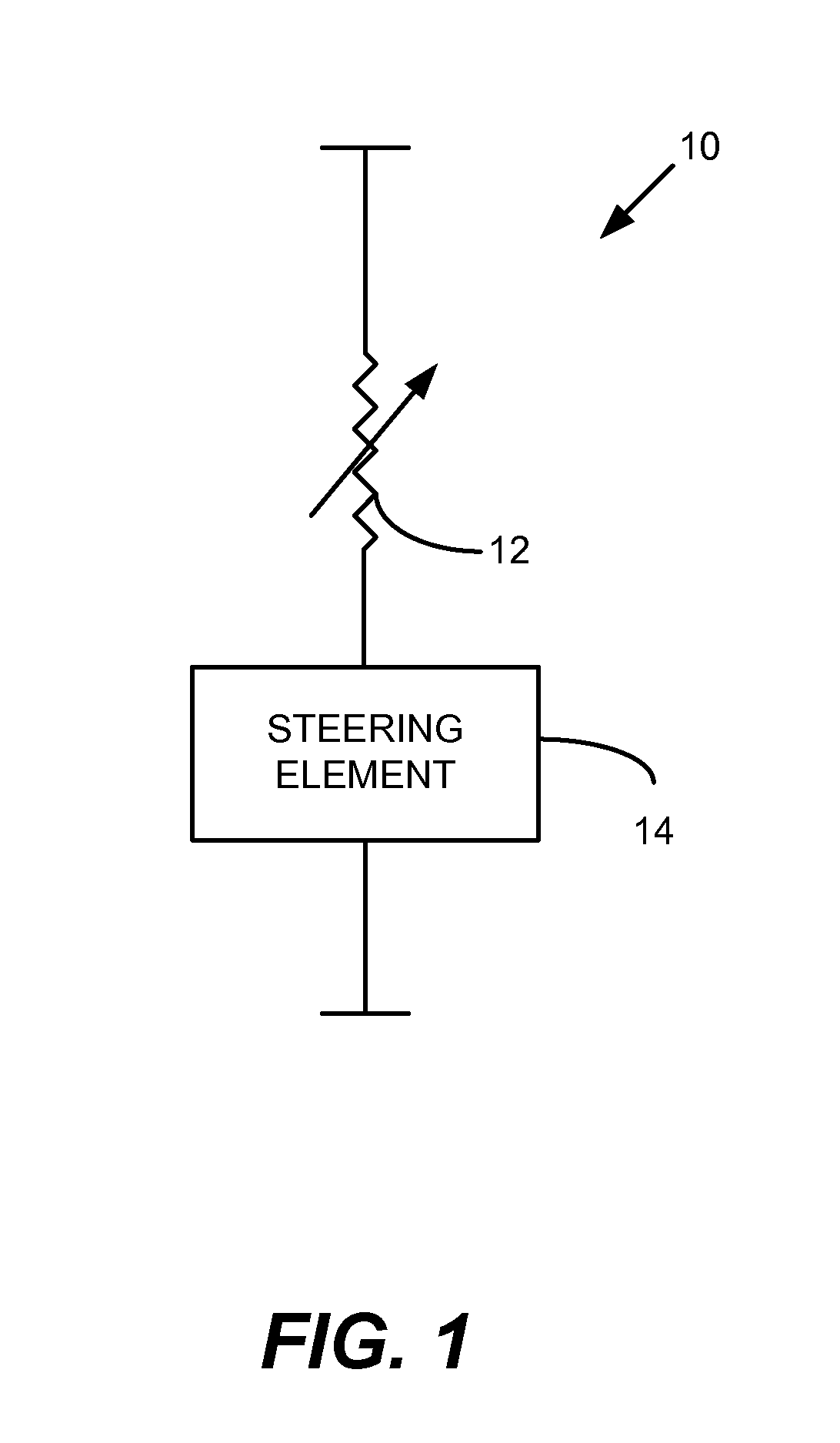

[0018]Indeed, some carbon-based materials have demonstrated reversible resistivity-switching memory properties on lab-scale devices with a 100× separation between ON and OFF states and mid-to-high range resistance changes. Such a separation between ON and OFF states renders carbon-based materials viable candidates for memory cells formed using the carbon materials in memory elements in series with steering elements, such as tunnel junctions, diodes, thin film transistors, or the like.

[0019]A carbon-based resistivity-switching material may be characterized by its...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com