Carbon nitride-nickel titanate composite material and preparation method and application thereof

A composite material, carbon nitride technology, applied in chemical instruments and methods, chemical/physical process, physical/chemical process catalyst, etc., can solve the problem of composite material synthesis work that has not yet been reported, and achieve easy control and stability of reaction conditions. Strong performance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

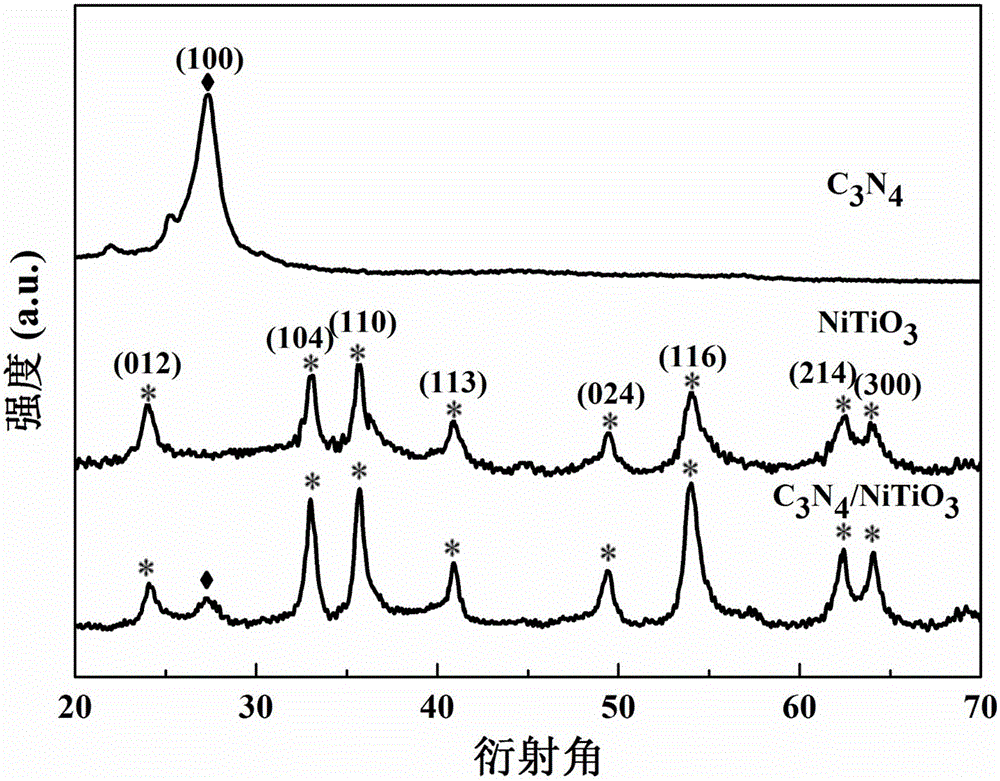

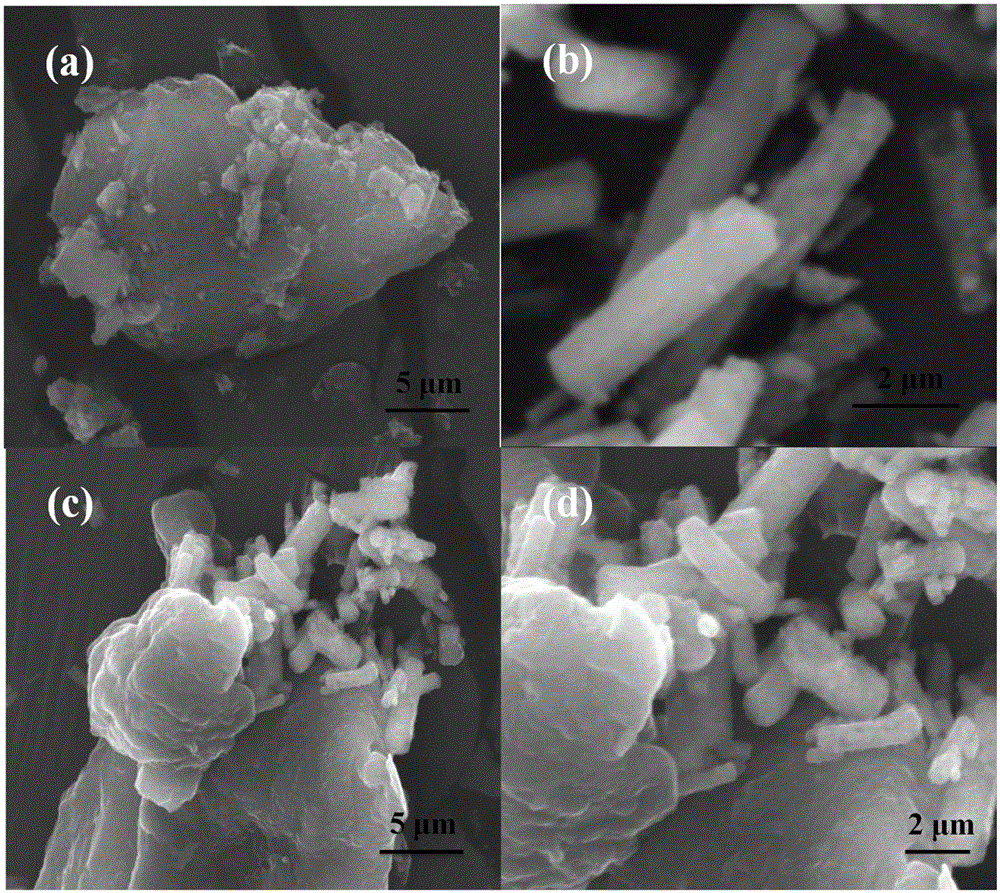

[0042] A carbon nitride-nickel titanate composite material of the present invention comprises carbon nitride and nickel titanate, wherein the carbon nitride is block-shaped, nickel titanate is rod-shaped, and the rod-shaped nickel titanate is deposited on the block-shaped nitrided Carbon surface, in which the mass fraction of carbon nitride is 18.4%.

[0043] respectively for g-C 3 N 4 , NiTiO 3 And the carbon nitride-nickel titanate composite material (g-C 3 N4 / NiTiO 3 ) The specific surface area is detected by BET measurement, g-C 3 N 4 , NiTiO 3 And the carbon nitride-nickel titanate composite material (g-C 3 N 4 / NiTiO 3 ) The specific surface area is 10.238m 2 g ?1 , 57.138m 2 g ?1 , 61.284m 2 g ?1 , see g-C 3 N 4 / NiTiO 3 The specific surface area of the material is larger than the two monomers; the high specific surface area can provide more active sites for adsorbing pollutants, which contributes to photocatalysis. Therefore, the carbon nitride-nic...

Embodiment 2

[0052] A carbon nitride-nickel titanate composite material of the present invention comprises carbon nitride and nickel titanate, wherein the carbon nitride is block-shaped, nickel titanate is rod-shaped, and the rod-shaped nickel titanate is deposited on the block-shaped nitrided Carbon surface, wherein the mass fraction of carbon nitride is 10%.

[0053] A method for preparing the carbon nitride-nickel titanate composite material of the above-mentioned embodiment differs from the method of embodiment 1 only in that the amount of dicyandiamide in step (1) is 150 mg, and the rest of the steps are the same.

Embodiment 3

[0055] A carbon nitride-nickel titanate composite material of the present invention comprises carbon nitride and nickel titanate, wherein the carbon nitride is block-shaped, nickel titanate is rod-shaped, and the rod-shaped nickel titanate is deposited on the block-shaped nitrided Carbon surface, in which the mass fraction of carbon nitride is 27.3%.

[0056] A method for preparing the carbon nitride-nickel titanate composite material of the above-mentioned embodiment differs from the method of embodiment 1 only in that the amount of dicyandiamide in step (1) is 500 mg, and the rest of the steps are the same.

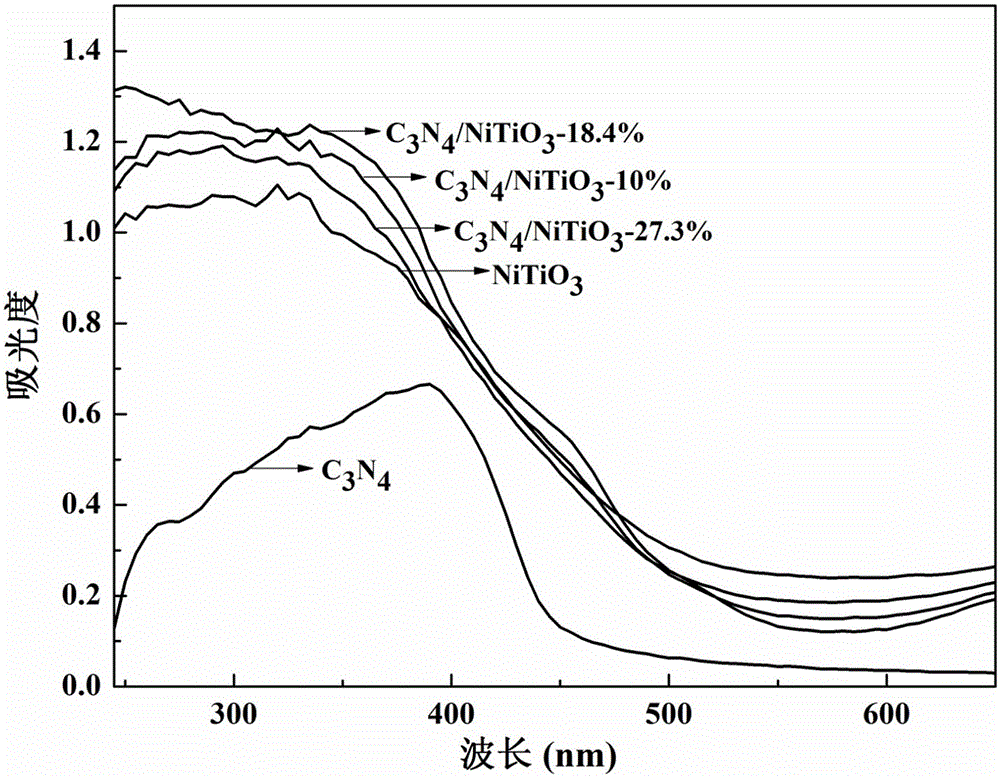

[0057] respectively for g-C 3 N 4 , NiTiO 3 And the carbon nitride-nickel titanate composite material of embodiment 1~3 carries out ultraviolet-visible diffuse reflection absorption spectrum detection, image 3 for g-C 3 N 4 , NiTiO 3 And the ultraviolet-visible diffuse reflection absorption spectrum corresponding to the carbon nitride-nickel titanate composite ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com