Lithium-enriched ternary anode material of power lithium-ion battery and preparation method of lithium-enriched ternary anode material

A lithium-ion battery and cathode material technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problem of low capacity and achieve the effects of high capacity, uniform distribution and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

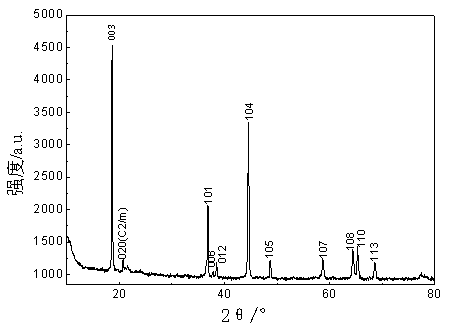

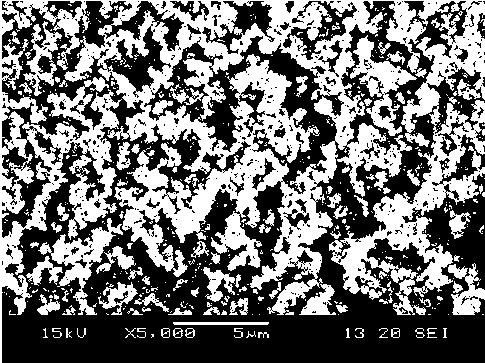

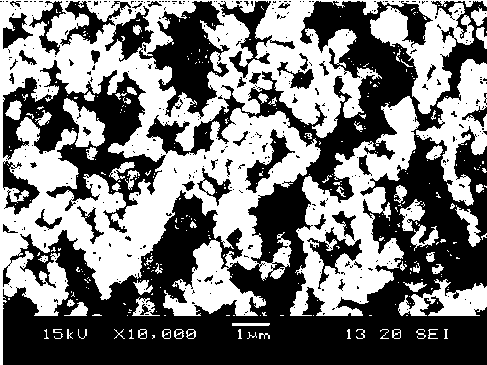

[0041] A lithium-rich ternary cathode material for power-type lithium-ion batteries, whose molecular formula is Li 1.2 Ni 0.13 Co 0.13 Mn 0.54 O 2 .

[0042] The above-mentioned lithium-rich ternary cathode material for power lithium-ion battery Li 1.2 Ni 0.13 Co 0.13 Mn 0.54 O 2 The preparation method specifically includes the following steps:

[0043] (1) Dissolve 3.2136g lithium acetate, 0.8302g cobalt acetate, 0.8294g nickel acetate, and 3.2678g manganese acetate in deionized water to form solution 1;

[0044] The amounts of lithium acetate, nickel acetate, cobalt acetate, and manganese acetate used above are calculated based on the molar ratio of Li:Co:Ni:Mn:O, that is, Li:Co:Ni:Mn:O is 1.26:0.13:0.13:0.54: 2;

[0045] The lithium acetate used above is excessively 5% to make up for the loss of lithium during subsequent calcination;

[0046] (2) Dissolve 4.2028g citric acid citric acid in deionized water to form solution 2;

[0047] The amount of citric acid used above is calculated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com