Method for producing low Pt content electro-catalyst by microwave

An electrocatalyst and microwave technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of Pt-based alloy electrocatalysts that have not yet been discovered, and achieve the goal of preparing Mild conditions, strong controllability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

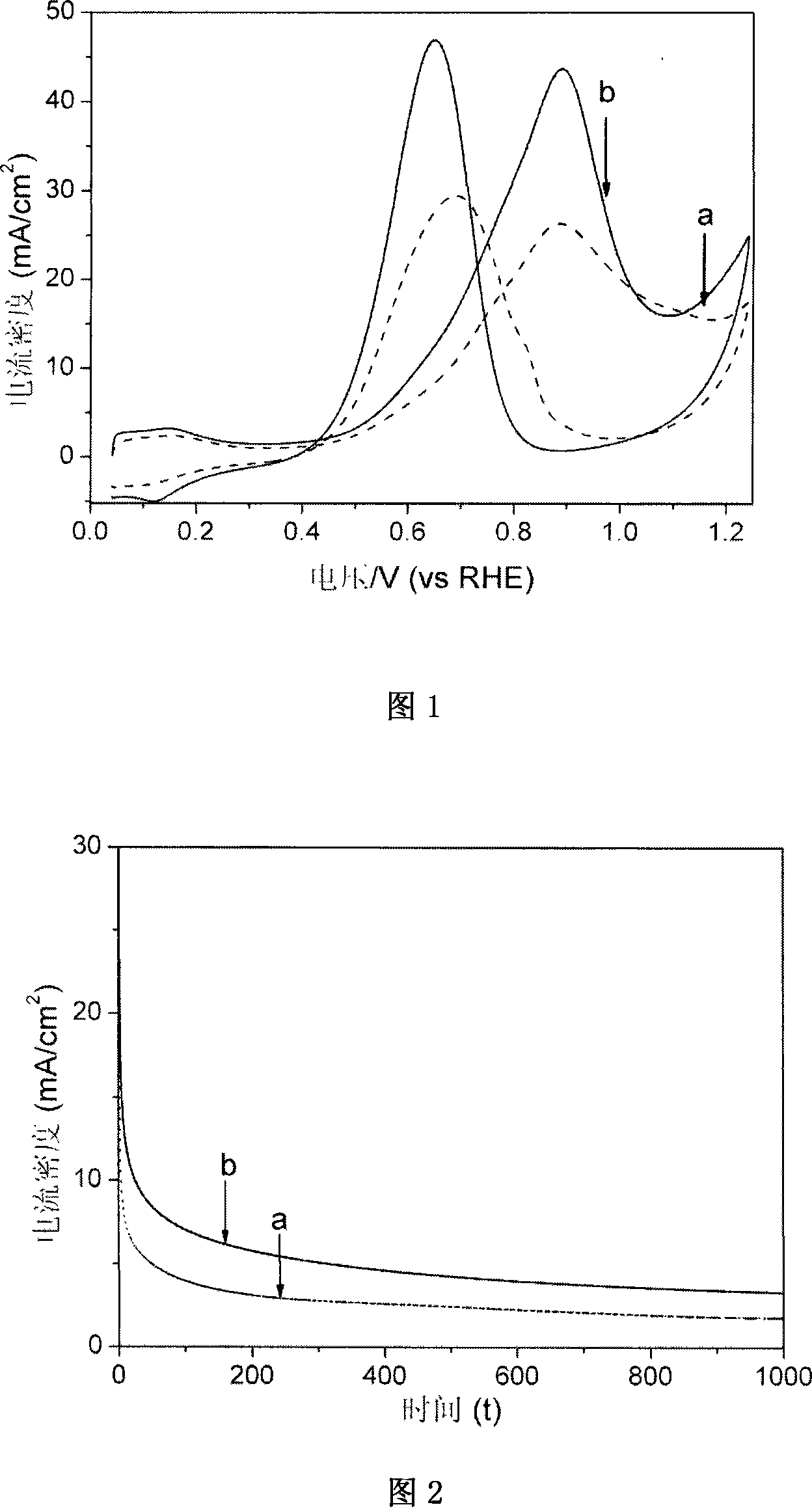

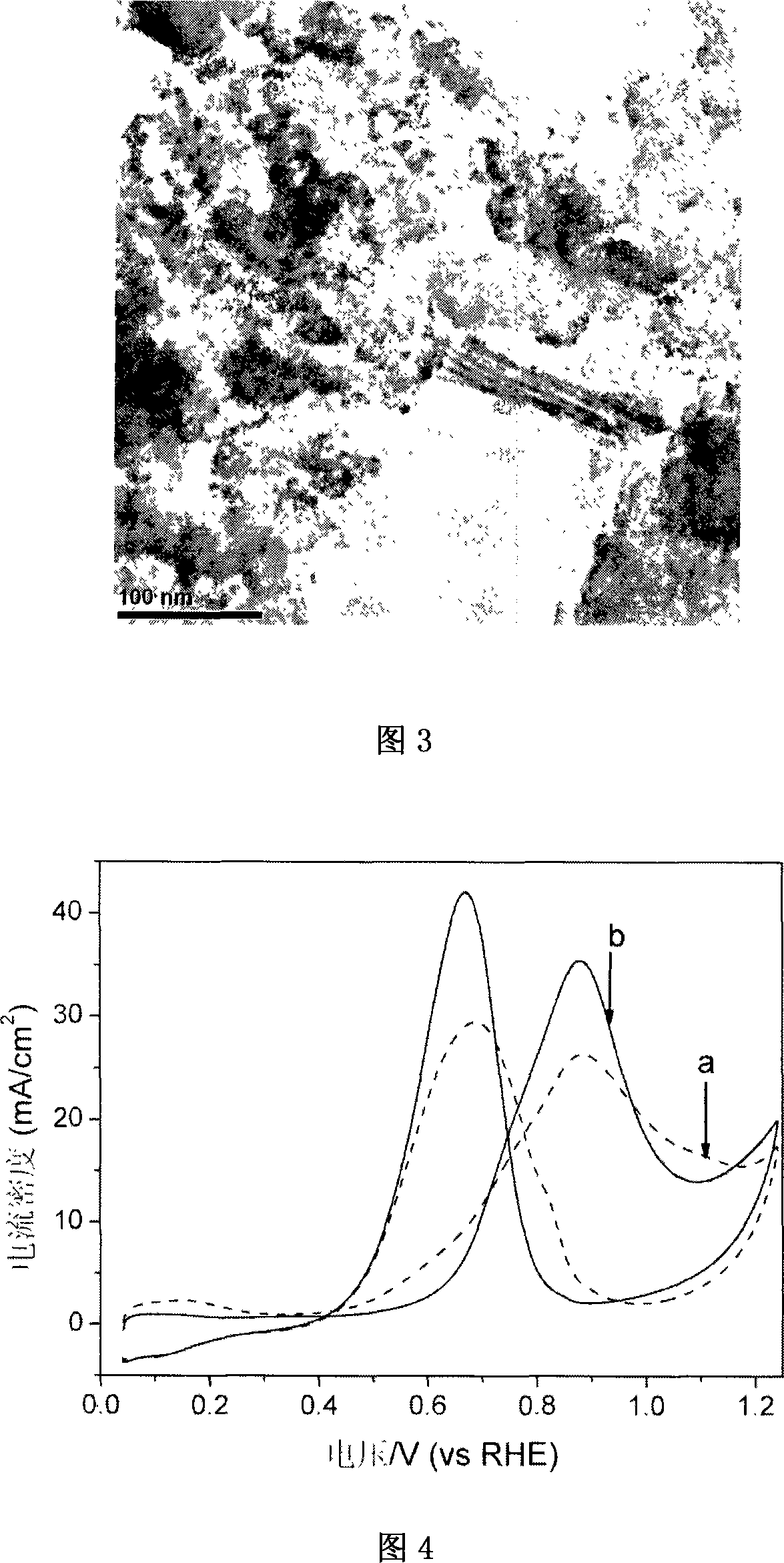

Embodiment 1

[0027] (1) Carry out high-energy ball milling after the Vulcan XC-72 carbon black of 5gCabot company is fully dried, then with 30wt%H 2 o 2 Soak at room temperature for 4 hours for pretreatment, after washing, put it into a vacuum drying oven for drying at 110° C. to obtain 4.8 g of pretreated carbon black.

[0028] (2) Pipette 0.33ml of chloroplatinic acid of 0.00753g / ml, 3.94ml of nickel acetate of 0.00253g / ml, weigh 0.0027gTiO 2 Nanotube powder and pretreated 0.02g carbon black were added to a flask filled with 30ml ethylene glycol solution, and the pH value was adjusted with 0.5M NaOH solution to make it 10; ultrasonic 30min, mixed, and then placed in a condensing In the microwave oven of the reflux tube, the reaction was heated with a power of 195W for 10min.

[0029] (3) The reaction product was placed for 12 hours, then suction-filtered, washed three times with 75°C double-pure water, dried in a 60°C vacuum oven for 12 hours after suction filtration, and ground to obt...

Embodiment 2

[0034] (1) Carry out high-energy ball milling after the Vulcan XC-72 carbon black of 5g Cabot Company is fully dried, then use 30wt%H 2 o 2 Soak at room temperature for 4 hours for pretreatment, after washing, put it into a vacuum drying oven for drying at 110° C. to obtain 4.8 g of pretreated carbon black.

[0035] (2) Pipette 0.8ml of chloroplatinic acid of 0.00753g / ml, 4.79ml of nickel acetate of 0.00253g / ml, weigh 0.0029gTiO 2 Nanotube powder and 0.02g of pretreated carbon black were added to a flask filled with 30ml of ethylene glycol solution, and the pH value was adjusted with 0.5M NaOH solution to make it 10; ultrasonic 30min, mixed, and then placed in a condensing In the microwave oven of the reflux tube, the reaction was heated with a power of 195W for 10min.

[0036] (3) The reaction product was placed for 12 hours, then suction-filtered, washed three times with 75°C double-pure water, dried in a 60°C vacuum oven for 12 hours after suction filtration, and ground t...

Embodiment 3

[0039] (1) Carry out high-energy ball milling after the Vulcan XC-72 carbon black of 5g Cabot Company is fully dried, then use 30wt%H 2 o 2 Soak at room temperature for 4 hours for pretreatment, after washing, put it into a vacuum drying oven for drying at 110° C. to obtain 4.8 g of pretreated carbon black.

[0040] (2) Pipette 1.86ml of chloroplatinic acid of 0.00753g / ml, 4.79ml of nickel acetate of 0.00253g / ml, weigh 0.0029gTiO 2 Nanotube powder and 0.02g of pretreated carbon black were added to a flask filled with 30ml of ethylene glycol solution, and the pH value was adjusted with 0.5M NaOH solution to make it 10; ultrasonic 30min, mixed, and then placed in a condensing In the microwave oven of the reflux tube, the reaction was heated with a power of 195W for 10min.

[0041] (3) The reaction product was placed for 12 hours, then suction-filtered, washed three times with 75°C double-pure water, dried in a 60°C vacuum oven for 12 hours after suction filtration, and ground ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com