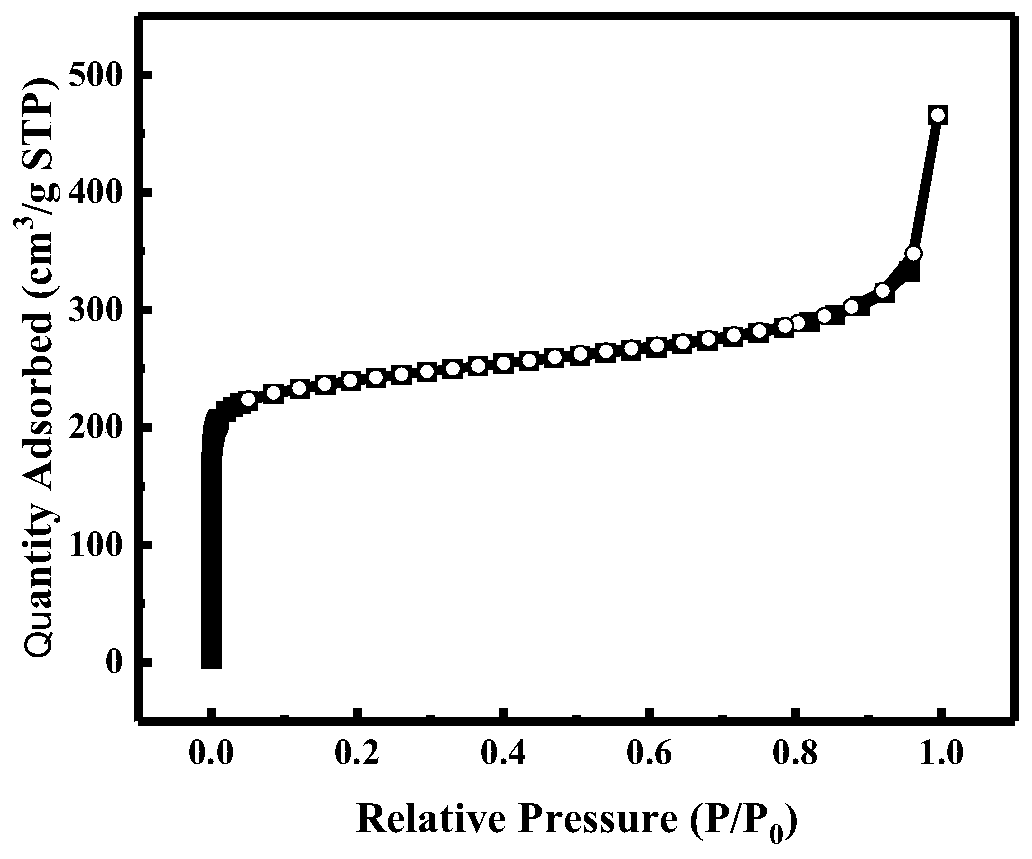

Method for preparing sponge-shaped porous carbon fiber membrane

A porous carbon fiber and sponge-like technology, applied in the field of new materials and chemical industry, can solve problems such as poor pore structure uniformity and fiber continuity, hinder material performance, etc., achieve uniform distribution, increase filling density, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of a spongy porous carbon fiber membrane, the specific steps are:

[0038] (1) Prepare the precursor spinning solution: Dissolve 15g of polyvinyl alcohol (Aladdin, PVA1788, molecular weight 84000) in 85g of water at 90°C and stir for 300min to prepare an aqueous solution of polyvinyl alcohol with a mass fraction of 15%, then at 30°C Dissolve 2.4 μg of boric acid in 57.6 μg of water and stir for 180 min, then add the above-mentioned 20 g of polyvinyl alcohol aqueous solution with a mass fraction of 15% and 20 g of polytetrafluoroethylene emulsion (purchased from Dongguan Xingwang Plastic Raw Materials Co., Ltd., solid content : 60%, particle size: 0.2 μm) stirred for 300min and mixed evenly to obtain the precursor solution;

[0039] (2) The obtained precursor spinning solution is subjected to electrospinning, and the charged solution forms a stable jet under the drive of the electric field force, stretches and solidifies in the air, and finally depos...

Embodiment 2

[0043] A preparation method of a spongy porous carbon fiber membrane, the specific steps are:

[0044] (1) Prepare the precursor spinning solution: dissolve 2 g of polyvinyl alcohol (Aladdin, PVA1788, molecular weight 84,000) in 18 g of water at 90° C. and stir for 300 min. After cooling to room temperature, add 60 μl of 4% boric acid solution and 20g polytetrafluoroethylene emulsion (purchased from Dongguan Xingwang Plastic Raw Materials Co., Ltd., solid content: 60%, particle size: 0.2 μm) was stirred for 300 minutes and mixed evenly to prepare a precursor solution;

[0045] (2) The obtained precursor spinning solution is subjected to electrospinning, and the charged solution forms a stable jet under the drive of the electric field force, stretches and solidifies in the air, and finally deposits on the collection device to obtain the precursor fiber film. Spinning is carried out in an air environment with a relative humidity of 50%, a constant temperature thermal field of 30...

Embodiment 3

[0049] A method for preparing a 3D spongy whole body porous carbon fiber membrane, the specific steps are:

[0050] (1) Configure the precursor spinning solution: Dissolve 2g of polyvinylpyrrolidone (Aladdin, K88-96, molecular weight 1,300,000) in 18g of solvent water at 30°C and stir for 120min, then add 60μl of 4% boric acid solution and 20g polytetrafluoroethylene emulsion (purchased from Dongguan Xingwang Plastic Raw Materials Co., Ltd., solid content: 60%, particle size: 0.2 μm), stirred for 300 minutes, and mixed evenly to prepare a precursor solution;

[0051] (2) The obtained precursor spinning solution is subjected to electrospinning to obtain a precursor fiber film, and the electrospinning is carried out in an air environment with a relative humidity of 35%, and a constant temperature heat field of 30°C is applied in the spinning interval, and the receiving device The temperature of the electrospinning is 30°C, and the parameters of the electrospinning are: perfusion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com