In-situ carbon coating method for lithium iron phosphate

A technology of lithium iron phosphate and carbon coating, which is applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of poor conductivity and uneven carbon coating, achieve uniform carbon coating, simple process, and benefit The effect of commercialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Dissolve 20g of polyvinyl alcohol (PVA) in 80mL of deionized water to form a solution with a PVA content of 20wt%;

[0026] Pour 72g of hydrothermally synthesized lithium iron phosphate powder into the above PVA solution, and form a suspension after fully stirring. The mass ratio between the carbon brought in by the organic carbon source material and lithium iron phosphate is 15%;

[0027] Pour the above solution into 200mL acetone solvent, stir and let stand for 1h;

[0028] The above solution was filtered, and the obtained powder was vacuum-dried at 100°C; its SEM photo is as follows figure 1 shown.

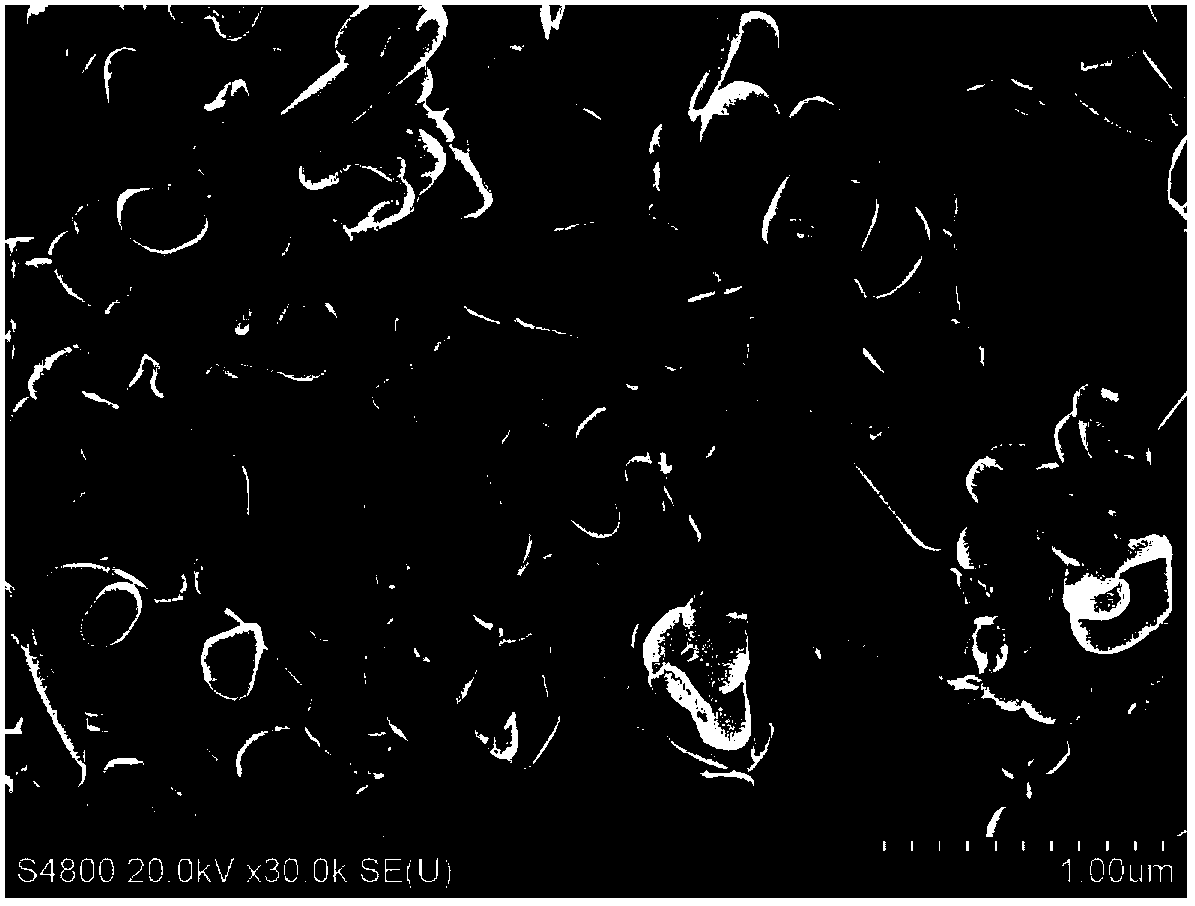

[0029] The above powder was kept at 600°C for 5 hours under a nitrogen atmosphere to obtain a uniform carbon-coated lithium iron phosphate material. The SEM photo is as follows: figure 2 shown.

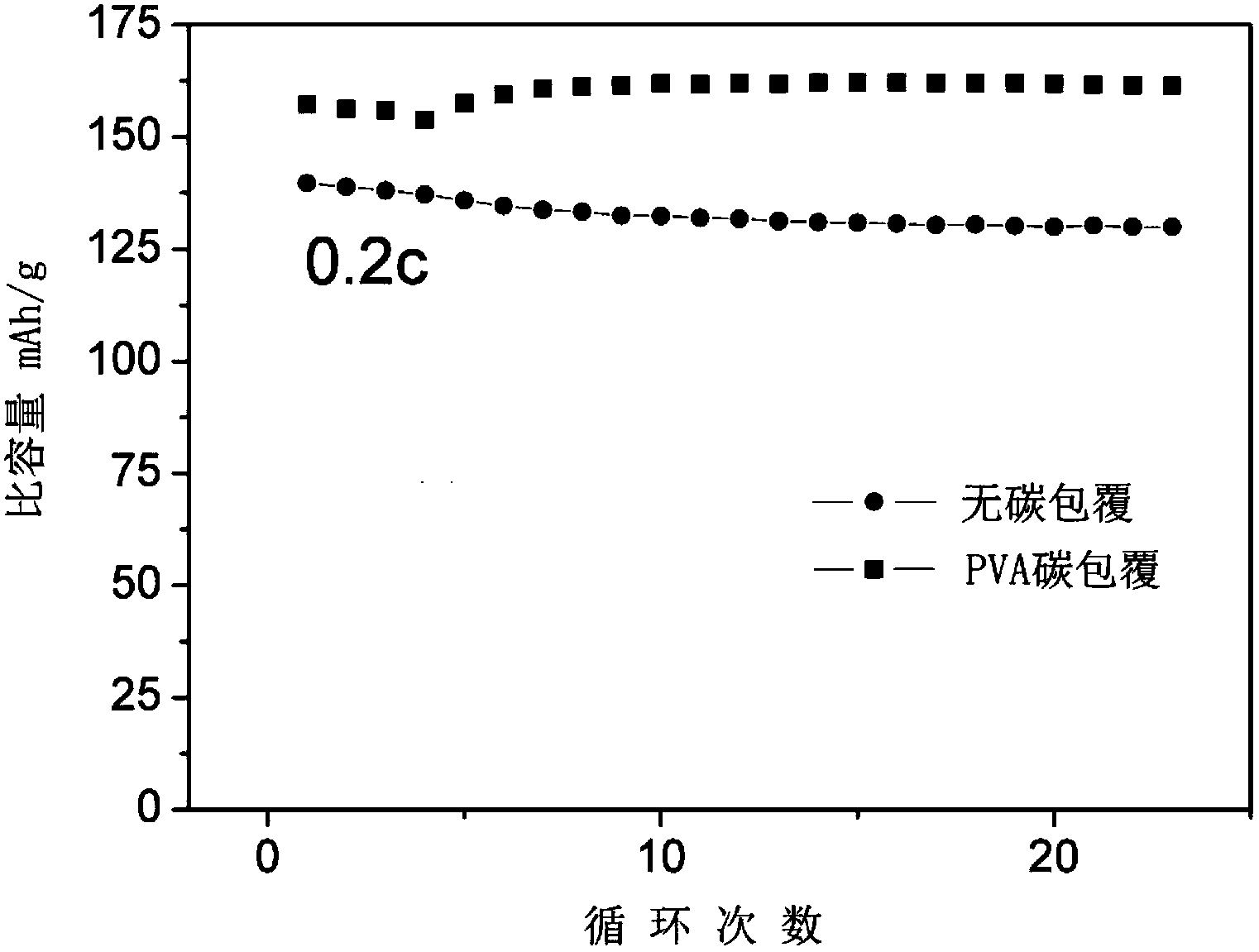

[0030] The cycle curves (0.2C) of the carbon-coated lithium iron phosphate material prepared in this example and the non-carbon-coated lithium iron phosphate are as follows ...

Embodiment 2

[0032] 1 gram of PVA was dissolved in 99mL of deionized water to form a solution with a PVA content of 1wt%;

[0033] Pour 18 grams of hydrothermally synthesized lithium iron phosphate powder and 0.9 grams of conductive carbon black into the PVA solution, and form a suspension after fully stirring. The mass ratio between the carbon brought by PVA and lithium iron phosphate is 3%. The mass ratio between the carbon carried by the conductive carbon black and lithium iron phosphate is 5%;

[0034] Pour the above solution into 200mL acetone solvent, stir and let stand for 1h;

[0035] The above solution was filtered, and the obtained powder was vacuum-dried at 100°C;

[0036] The above powder was heat-treated at 800°C for 5 hours under a nitrogen atmosphere to obtain a uniform carbon-coated lithium iron phosphate material;

Embodiment 3

[0038] Dissolve 10 grams of polyvinyl butyral (PVB) in 114 mL (90 g) of methanol to form a solution with a PVB content of 10 wt %;

[0039] Pour 135 grams of hydrothermally synthesized lithium iron phosphate powder into the above PVB solution, and form a suspension after fully stirring. The mass ratio between the carbon brought by PVB and lithium iron phosphate is 5%;

[0040] Pour the above solution into 200mL water, stir and let stand for 1h;

[0041] The above solution was filtered, and the obtained powder was vacuum-dried at 100°C;

[0042] The above powder is heat-treated at 600°C and 5°C under a nitrogen atmosphere to obtain a uniform carbon-coated lithium iron phosphate material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com