Zinc-nickel static single fluid flow battery

A flow battery and static technology, which is applied in the field of zinc-nickel static single flow battery, can solve the problems of limited effective use of single battery space, deterioration of battery cycle performance, and reduction of battery discharge capacity, etc., to achieve small size and easy portability , reducing the effect of self-discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

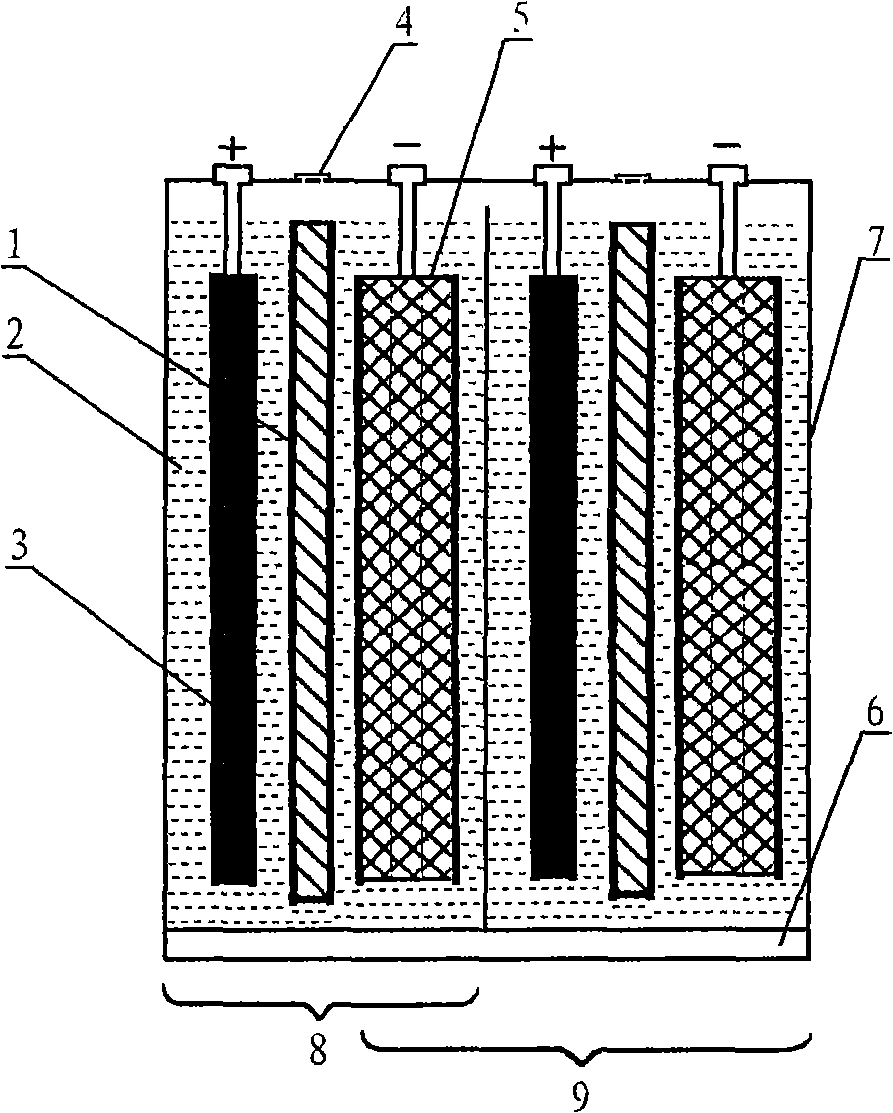

[0022] Such as figure 1 As shown, the zinc-nickel static single-flow battery is composed of a battery stack 9, an electrolyte 2, a battery casing 7, and a precipitation tank 6, which are composed of multiple battery cells 8. The battery cell 8 is composed of a nickel electrode 3, a positive electrode, and a deposition tank. The anode current collector 5 of zinc, the separator 1 and the liquid injection cover 4 are constituted. The negative active material is dissolved and stored in the electrolyte 2, and the two battery cells 8 connected in series in the battery stack 9 are connected in series with the positive and negative terminals; during the charge and discharge process, the active material dissolved in the electrolyte The soluble zinc salt of the substance is converted back and forth with the metallic zinc on the negative electrode current collector.

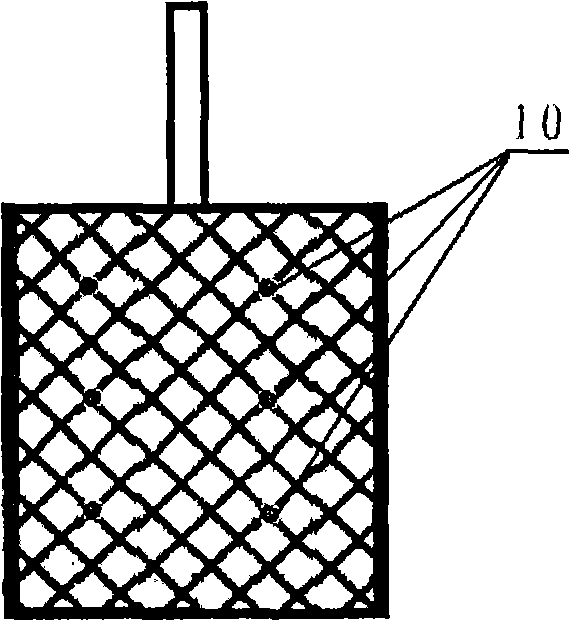

[0023] The production process of the copper mesh is as follows: fold the copper mesh into three equal lengths, and then clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com