Preparation method and application of nanometer nickel hydroxide and composite electrode thereof

A nickel hydroxide, composite electrode technology, applied in nickel oxide/nickel hydroxide, electrode manufacturing, battery electrodes, etc., can solve the problems of low packing density, short discharge time, easy to agglomerate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation of embodiment one nanometer nickel hydroxide

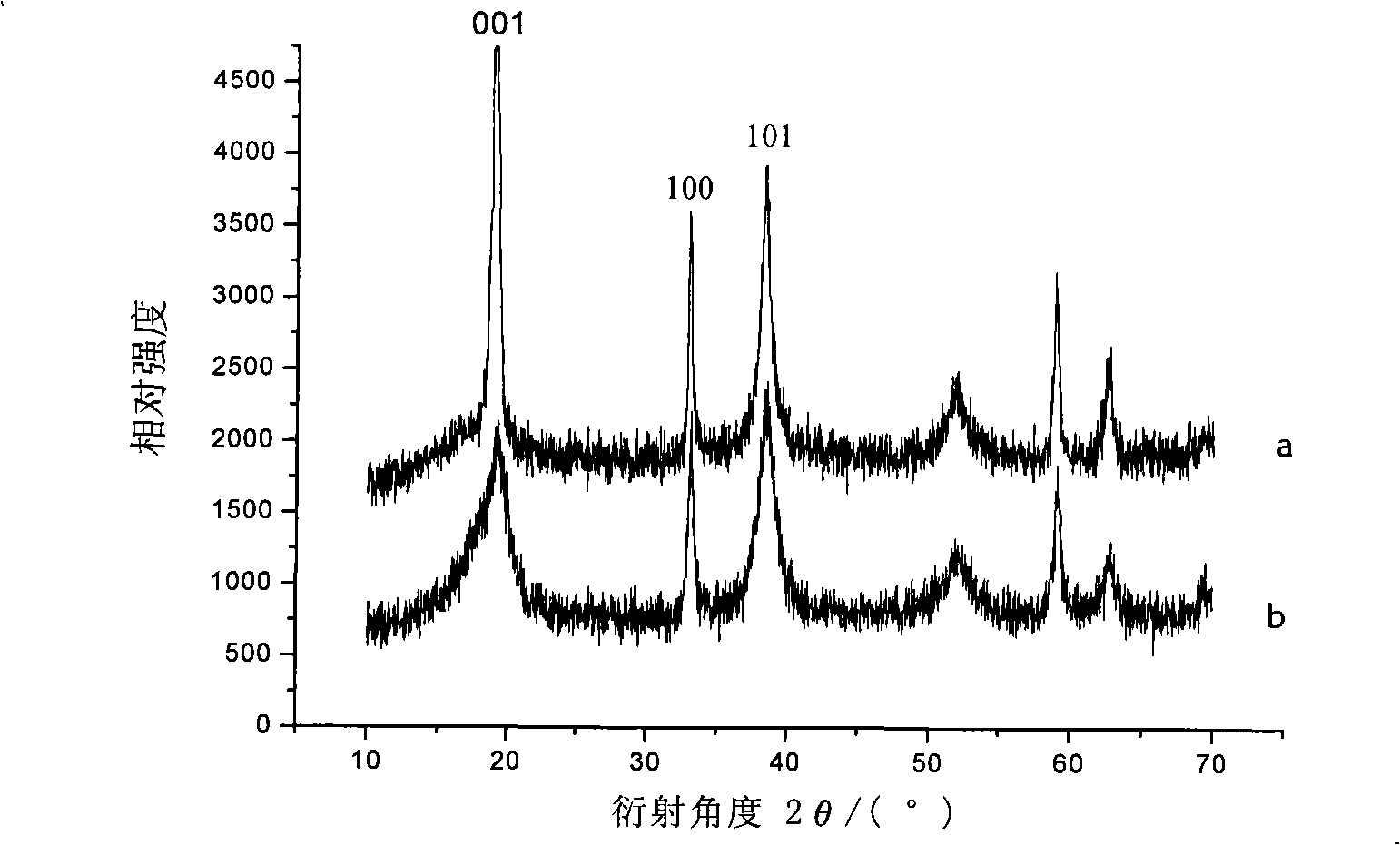

[0039] According to embodiment one step preparation concentration is the Ni(NO of 0.5mol / l 3 ) 2 ·6H 2 O solution 200ml and add 0.3g (mass ratio 3%) Polyethylene Glycol, 1mol / l Na (OH) solution 200ml and add ammoniacal liquor 11ml, two kinds of solutions are added dropwise and placed in the ultrasonic cleaner vibrating chamber ( Power 40W, frequency 40KHz) in the reaction vessel and constantly stirring, control the rate of addition and stirring speed (600 rpm), so that the reaction temperature of the solution in the reaction vessel remains at 60 ± 2 ° C, and the pH value remains at 10.50 ± 0.10. After the dropwise addition was completed, the stirring was continued for 2 to 4 hours. Then stand still, wash and filter, dry the composition in a drying oven at 90°C for more than 12 hours, take out and grind to obtain a sample, marked as s 1 . The XRD spectrum of its sample is attached figure 1 As shown in b...

Embodiment 2

[0041] Nano-Ni(OH) prepared by embodiment two different pH values 2 Bulk Density

[0042] Identical to other conditions and steps of Example 1, the pH value of the reaction solution was taken to be 9, 10, 10.5, 11, 11.5, 12 respectively, and six samples were prepared, and the bulk density was measured. The results are shown in the attached Figure 5 shown.

[0043] Active materialNi(OH) 2 The density is an important parameter to measure the electrochemical performance of materials. Figure 5 It shows that as the pH value of the solution increases, the bulk density first decreases and then increases.

Embodiment 3

[0044] Nano-Ni(OH) prepared by embodiment three different reaction temperatures 2 bulk density

[0045] The other conditions and steps are the same as those in Example 1, taking the reaction temperatures of 30, 40, 50, 55, 60, and 70°C respectively to prepare six samples and measure their bulk density. The results are shown in the attached Image 6 shown. Depend on Image 6 It can be seen that as the temperature increases, the bulk density of the sample decreases first and then increases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com