Metal organic framework/foamed nickel electrode material and preparation method and applications thereof

A metal-organic framework and electrode material technology, applied in the field of electrocatalytic materials, can solve the problems of reducing the active site of the catalyst, unsuitable for large-scale production, affecting the effect of the binder, etc., to achieve continuous and stable catalytic effect, theoretical and practical significance Significant, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

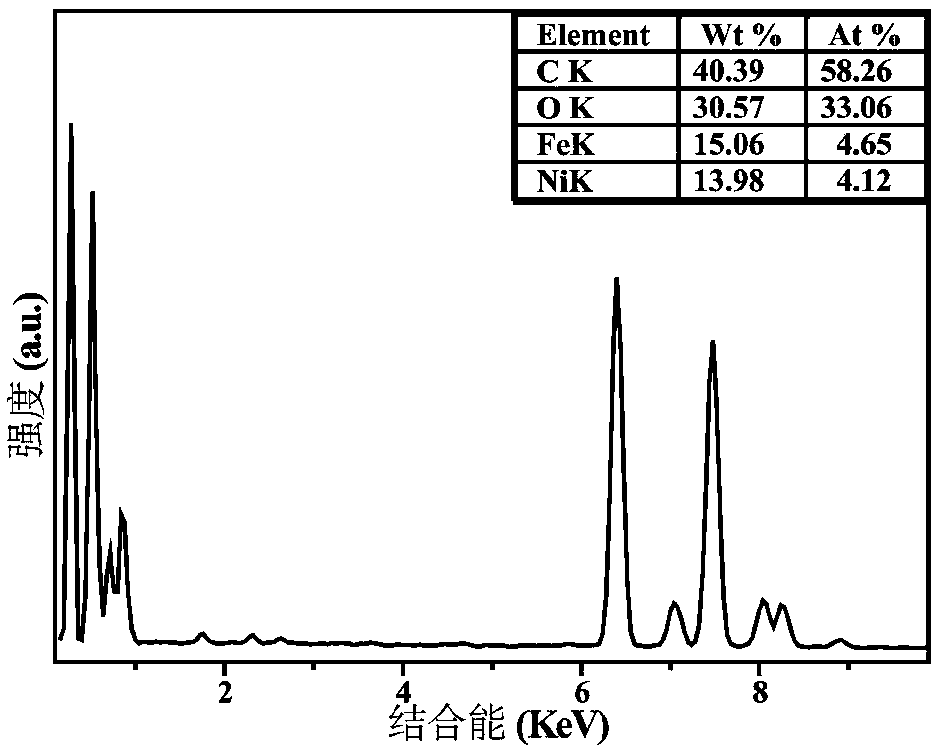

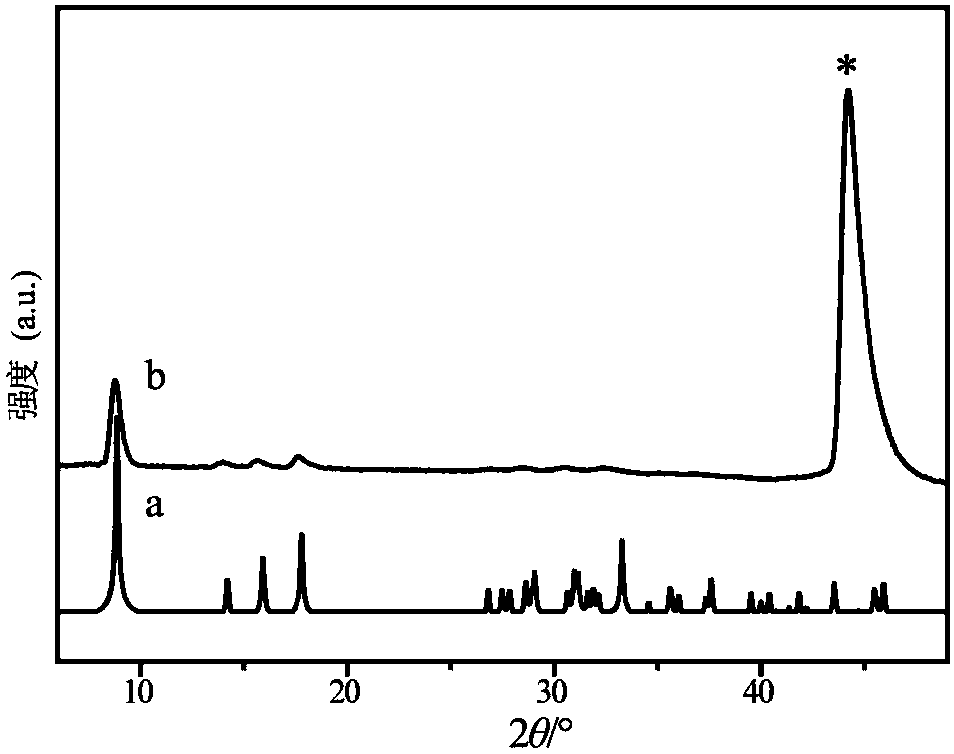

[0032] The embodiment of the present invention provides a method for preparing a metal organic framework / nickel foam electrode material, and the specific steps are as follows:

[0033] S1. Pretreat the nickel foam sheet, cut the nickel foam sheet into a rectangle of 3cm×1cm, place it in dilute hydrochloric acid for 15 minutes to remove the surface oxide layer, then rinse it with deionized water, then place it in acetone for 15 minutes to remove the surface organic matter, then rinsed with deionized water, and finally placed in an oven, dried at 60°C for 3 hours, and stored for later use;

[0034] S2, weigh 0.48mmol of FeCl 2 4H 2 O and 0.48mmol of terephthalic acid, then add 10.5mL N, N-dimethylformamide, 0.75mL ethanol and 0.75mL deionized water, mix well and place in a 30mL polytetrafluoroethylene reactor, then Add the foamed nickel flakes pretreated in step S1, seal the polytetrafluoroethylene reactor, place it in an oven, heat and react at 125°C for 12h, then cool natura...

Embodiment 2

[0040] The embodiment of the present invention provides a method for preparing a metal organic framework / nickel foam electrode material, and the specific steps are as follows:

[0041] S1. Pretreat the foamed nickel sheet, cut the foamed nickel sheet into a rectangle of 3cm×2cm, put it in dilute hydrochloric acid for 20 minutes to remove the surface oxide layer, then rinse it with deionized water, and then place it in acetone for 20 minutes to remove the surface organic matter, then rinsed with deionized water, and finally placed in an oven, dried at 60°C for 5 hours, and stored for later use;

[0042] S2, weigh 0.48mmol of FeCl 2 4H 2 O and 0.45mmol of terephthalic acid, then add 11mL N, N-dimethylformamide, 0.8mL ethanol and 0.8mL deionized water, mix well and place in a 50mL polytetrafluoroethylene reactor, and then add Add the pretreated nickel foam flakes in step S1, seal the polytetrafluoroethylene reactor, place it in an oven, heat it at 130°C for 14 hours, then cool ...

Embodiment 3

[0046] The embodiment of the present invention provides a method for preparing a metal organic framework / nickel foam electrode material, and the specific steps are as follows:

[0047] S1. Pretreat the foamed nickel sheet, cut the foamed nickel sheet into a rectangle of 3cm×0.8cm, place it in dilute hydrochloric acid for 10 minutes to remove the surface oxide layer, then rinse it with deionized water, then place it in acetone for 10 minutes to remove the oxide layer. The organic matter on the surface is then rinsed with deionized water, and finally placed in an oven, dried at 60°C for 2 hours, and stored for later use;

[0048] S2, weigh 0.48mmol of FeCl 2 4H 2 O and 0.45mmol of terephthalic acid, then add 10mL N, N-dimethylformamide, 0.7mL ethanol and 0.7mL deionized water, mix well and place in a 25mL polytetrafluoroethylene reactor, and then add Add the pretreated nickel foam flakes in step S1, seal the polytetrafluoroethylene reactor, place it in an oven, heat and react ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com