Transition metal oxide/ graphene composite material and preparation method thereof

A transition metal and composite material technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of large volume change and capacity attenuation, and achieve the effect of simple process, small particle size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] with CuCl 2 2H 2 O as raw material, the CuCl 2 2H 2 O dissolved in deionized water to make 80 mL of CuCl 2 Concentration is the solution of 0.02mol / L, then add 20 milligrams of GO to make mixed solution; Place the mixed solution in the autoclave (filling degree 80%, volume percentage) that the capacity is 100 milliliters, add 0.25 gram surfactant CTAB and 40 μL of hydrazine hydrate, and then adjust the pH value to 11 with 6mol / L KOH aqueous solution, then seal the reaction vessel, react at 180°C for 12 hours, and cool to room temperature naturally; collect the solid reaction product, and pass the product through deionized water Alternately and repeatedly washing with absolute ethanol, drying to obtain 0.12g CuO / graphene composite material, wherein the weight percentage of graphene is 7%.

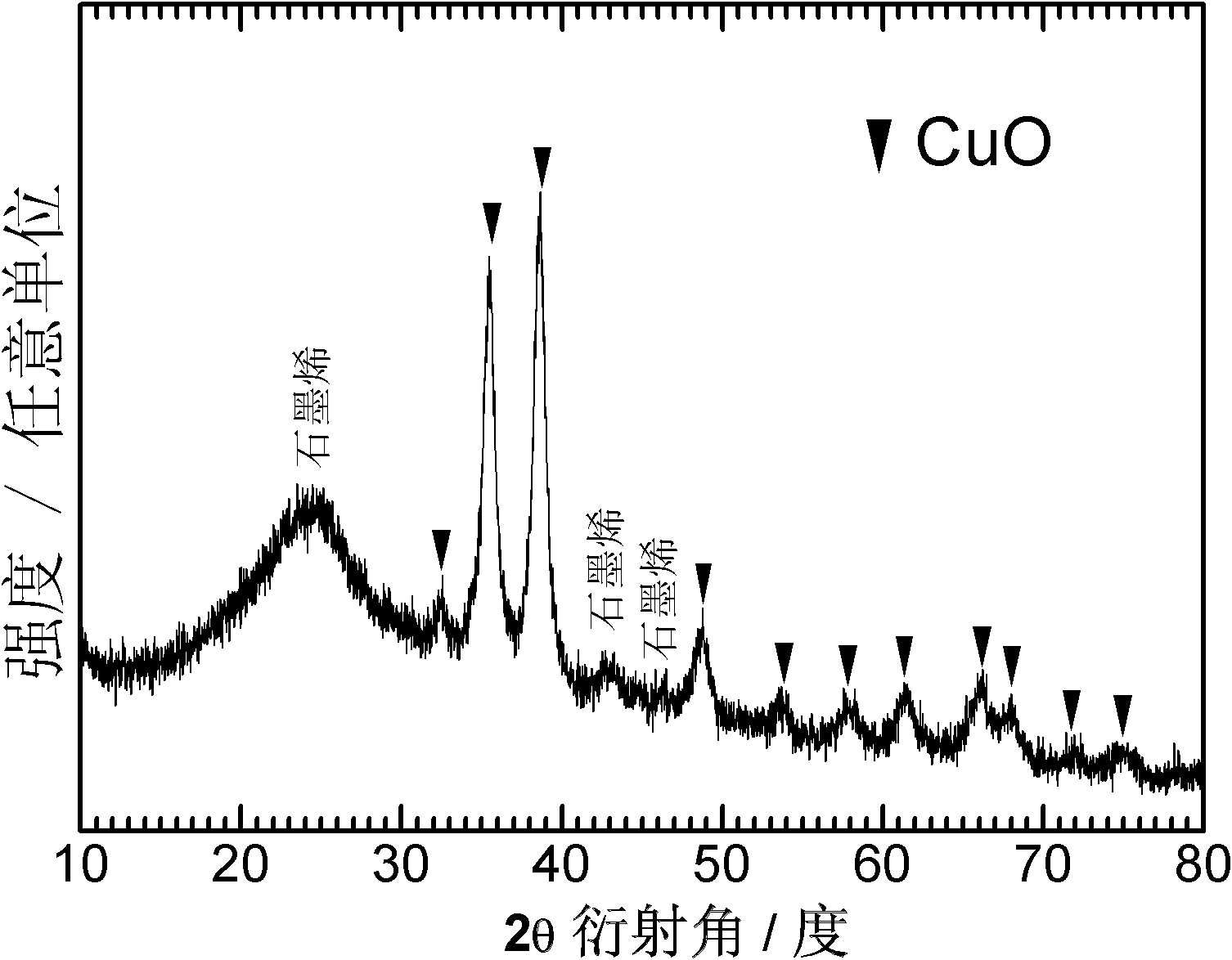

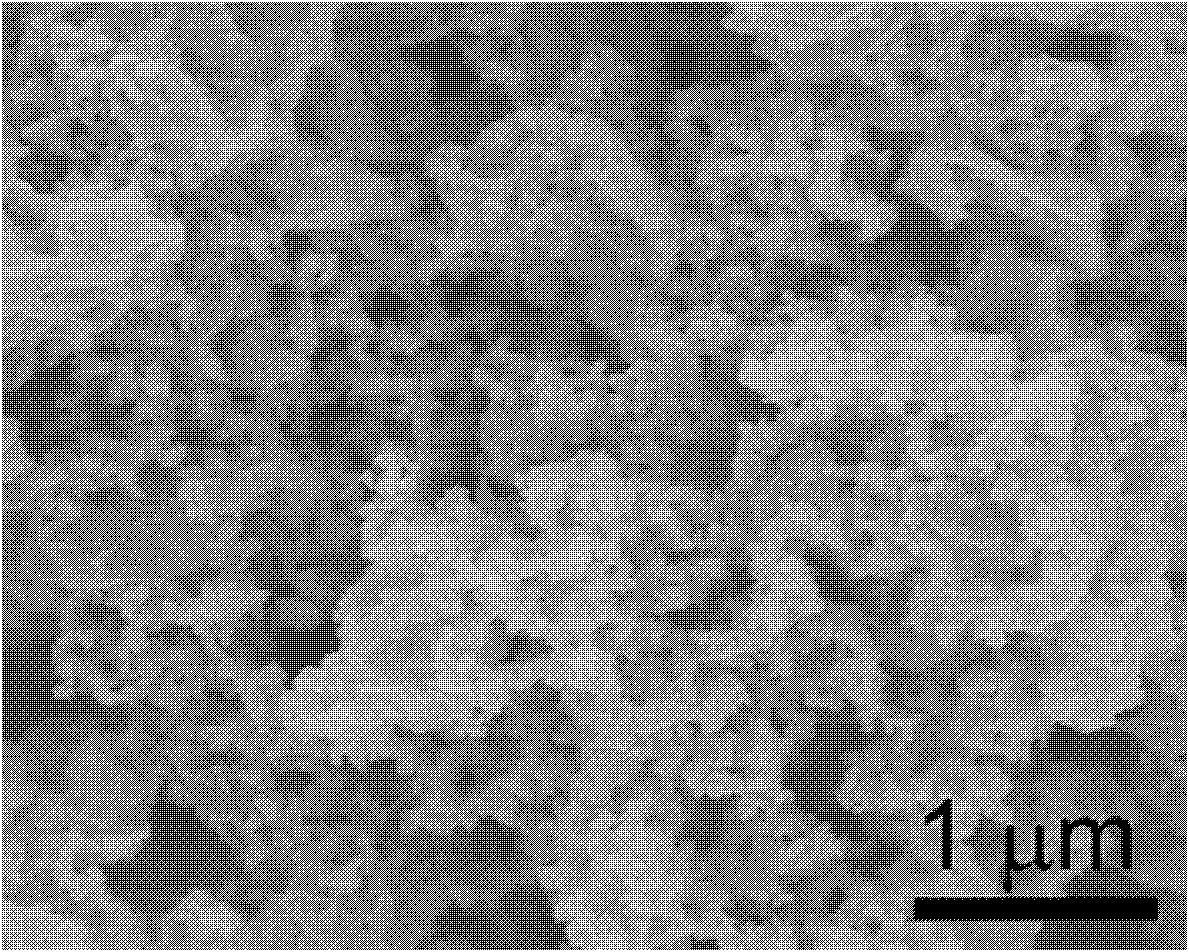

[0030] The X-ray diffraction pattern and the scanning electron microscope photo of the composite material of gained are respectively as follows figure 1 and figure 2 , it can b...

Embodiment 2

[0033] with FeCl 3 ·6H 2 O as raw material, FeCl 3 ·6H 2 O dissolved in ethylene glycol to make 80 mL of FeCl 3 Concentration is the solution of 0.03mol / L, add 15 milligrams of GO again and make mixed solution; The mixed solution is placed in the autoclave (filling degree 80%, volume percentage) that the capacity is 100 milliliters, add 0.3 gram surfactant PVP (The number of moles is converted to the molecular weight of N-vinylpyrrolidone monomer) and 30 μL of hydrazine hydrate, then adjust the pH value to 8 with 25 wt% ammonia water, then seal the reaction kettle, react at 200 ° C for 4 hours, and cool naturally to room temperature; the solid reaction product was collected, the product was washed alternately and repeatedly with deionized water and absolute ethanol, and dried to obtain 0.18g Fe 2 o 3 / graphene composite material, wherein the weight percentage of graphene is 4%.

[0034] It can be seen from the X-ray diffraction pattern and the scanning electron micrograp...

Embodiment 3

[0037] With Cr(NO 3 ) 3 9H 2 O as raw material, Cr(NO 3 ) 3 9H 2 O was dissolved in absolute ethanol to prepare 80 ml of Cr(NO 3 ) 3 Concentration is the solution of 0.05mol / L, add 40 milligrams of GO again and make mixed solution; The mixed solution is placed in the autoclave (filling degree 80%, volume percentage) that the capacity is 100 milliliters, add 0.5 gram surfactant SDS and 100 μL of hydrazine hydrate, and then adjust the pH value to 10 with 6mol / L NaOH aqueous solution, then seal the reaction vessel, react at 160°C for 24 hours, and cool to room temperature naturally; collect the solid reaction product, and pass the product through deionized water Wash with absolute ethanol alternately and repeatedly, and dry to obtain 0.3g Cr 2 o 3 / graphene composite material, wherein the weight percentage of graphene is 8%.

[0038] It can be seen from the X-ray diffraction pattern and the scanning electron micrograph of the composite material obtained that the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com