Lithium battery with polymer-coated sulfur/carbon composite material as anode

A carbon composite material and polymer technology, applied in the field of electrochemistry, can solve the problems of unsatisfactory polymer conductivity, poor retention, poor stability, etc., and achieve excellent high-rate charge and discharge performance, improve energy density, and inhibit dissolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

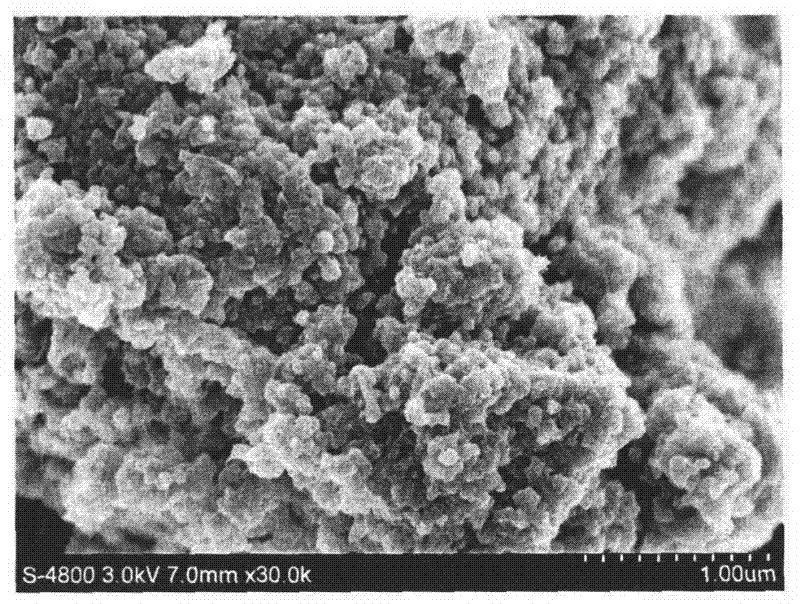

[0030]Preparation of polyaniline-coated sulfur / conductive carbon black composites and electrode sheets

[0031] Take by weighing 5.0 gram of sublimated sulfur and 5.0 gram of porous conductive carbon black (Ketjenblack EC600JD) and put into the agate ball mill jar, place the ball mill on the planetary ball mill after the agate ball mill jar is filled with high-purity argon in the glove box, the time is 2 hours, The rotational speed is 300 revolutions per minute. Then, the resulting mixture was transferred to a sealed container filled with an inert gas (argon), heat-treated in a muffle furnace, raised to 155° C. at a heating rate of 5° C. / min, and kept at this temperature for 12 hours. Obtain sulfur / conductive carbon black composite material.

[0032] Accurately weigh 4.0 g of the above-prepared sulfur / conductive carbon black composite material, put it into a three-necked flask filled with 250 ml of deionized water and 50 ml of acetone mixed solvent, ultrasonically and magneti...

Embodiment 2

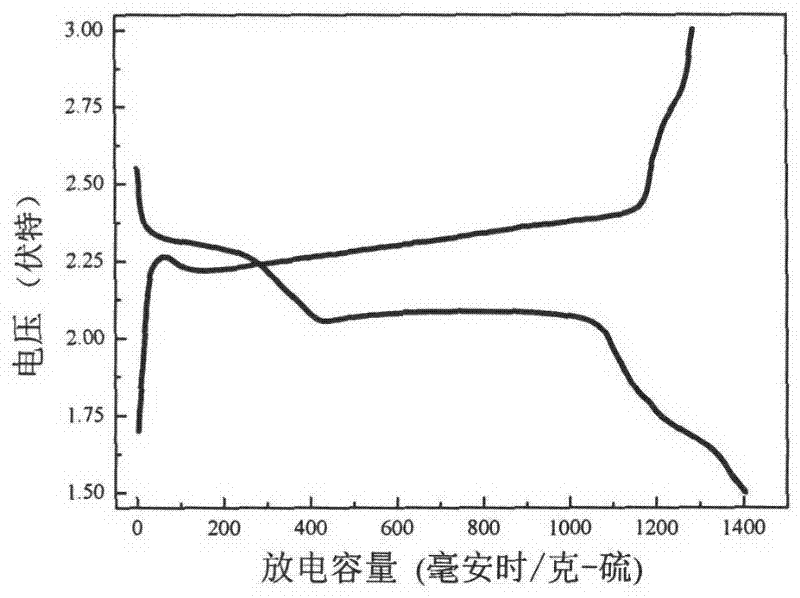

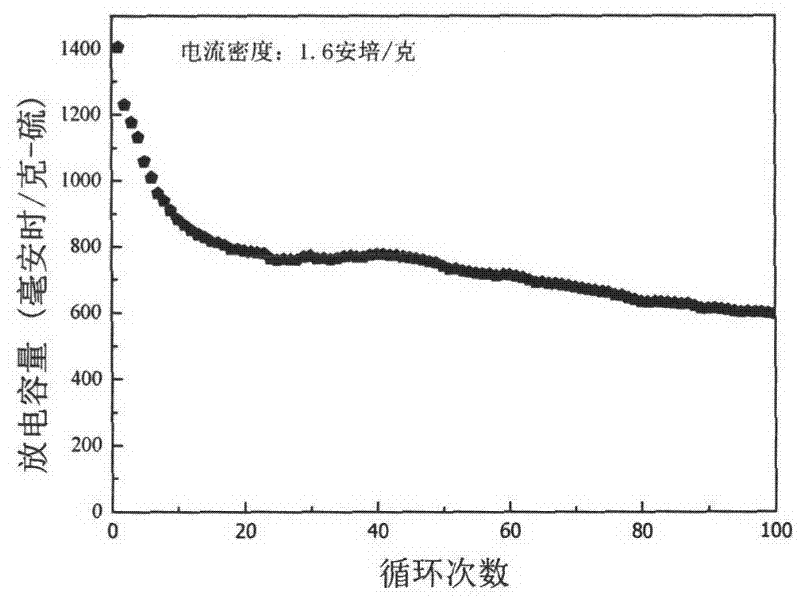

[0037] The quality of step (1) sublimated sulfur and porous conductive carbon black (Ketjenblack EC600JD) in Example 1 was determined as 7.0 grams and 3.0 grams respectively, and the others were the same as in Example 1. Under the current density of 1.6 amps / g, the first week charge and discharge capacity test results are as follows: Figure 4 shown.

Embodiment 3

[0039] In embodiment 1 (1) step porous conductive carbon black (Ketjenblack EC600JD) is changed into microporous superconducting carbon black (BP2000), the electrolyte in embodiment 1 (4) step electrolyte is 1.0 mol / liter The lithium bis(trifluoromethylsulfonyl)imide is changed into the lithium trifluoromethanesulfonate solution of 1.0 mol / liter of electrolyte, and others are the same as in Example 1. Under the current density of 1.6 amps / g, the first week charge and discharge capacity test results are as follows: Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com