Method for preparing graphene aerogel and graphene/ metallic oxide aerogel

A graphene airgel and graphene technology, applied in the direction of graphene, hybrid/electric double-layer capacitor manufacturing, hybrid capacitor electrodes, etc., can solve the problems of not using cross-linking agents, and achieve low price, environmental friendliness, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

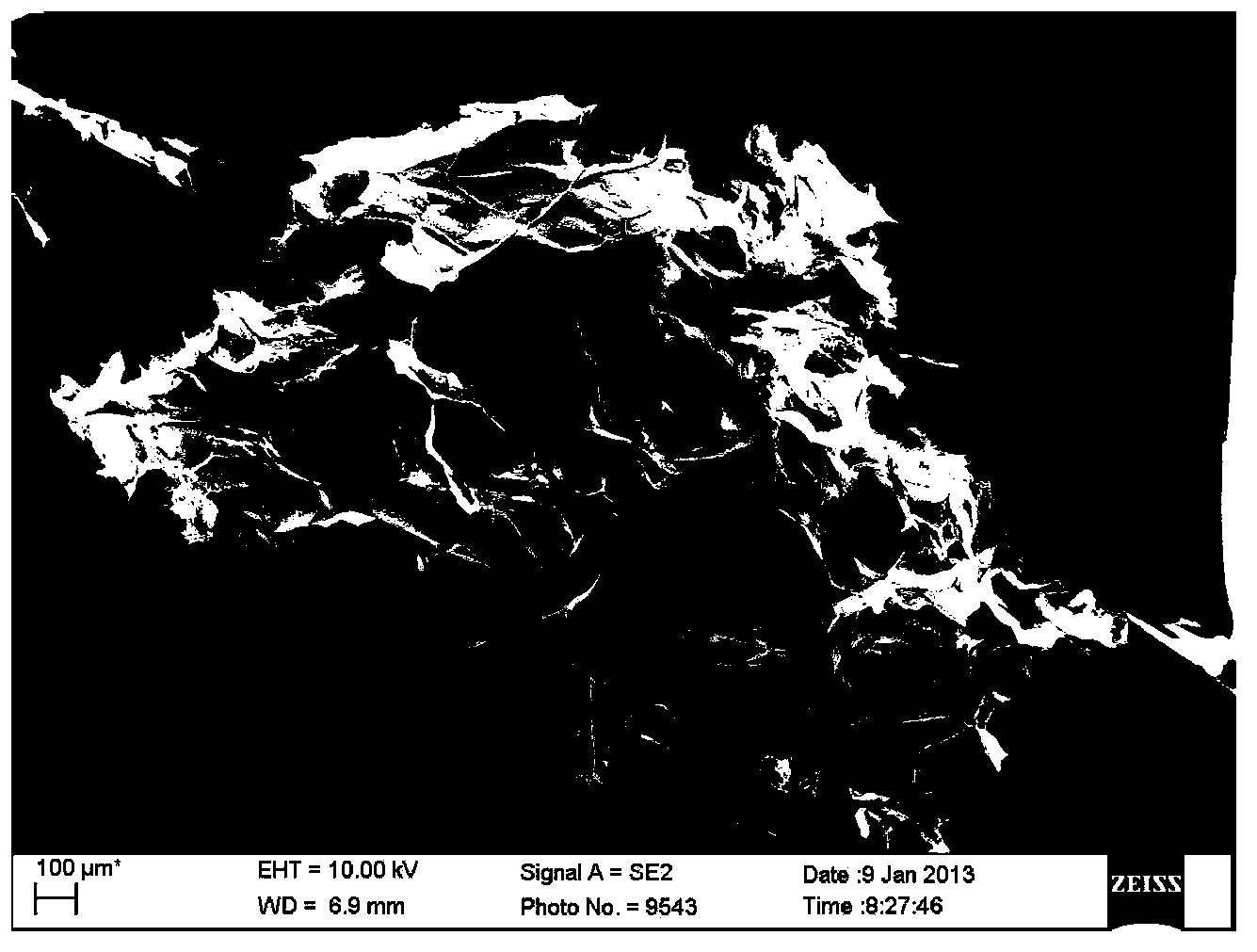

[0038] Firstly, the graphite oxide was ground to refine the particles, and then mixed with deionized water to form a graphite oxide aqueous solution with a concentration of 2 mg / mL. Then 2 mL of methanol was added to 15 mL of the aqueous solution of graphite oxide. Mechanically stir the obtained mixture for 1 hour and ultrasonically oscillate for 2 hours for dispersion treatment, then put it into a 25mL hydrothermal reaction kettle, place the assembled reaction kettle at a temperature of 120°C for 2 hours, and obtain graphene after cooling down naturally liquid gel. The prepared graphene liquid gel is dried by freeze-drying technology, and then the graphene aerogel is obtained. The obtained graphene airgel was placed in N 2 Calcination at 200°C for 1 h under gas protection for optimization treatment to obtain the final graphene airgel.

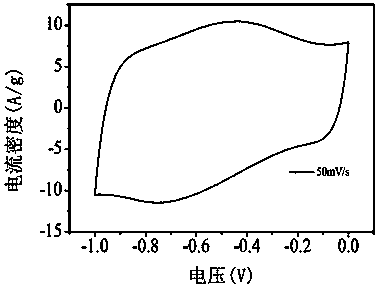

[0039] The obtained graphene airgel material is cut into thin slices of about 0.2 mg with a knife and placed in two pieces of nickel foam ...

Embodiment 2

[0041] Firstly, the graphite oxide was ground to refine particles, and then mixed with deionized water to prepare a graphite oxide aqueous solution with a concentration of 4 mg / mL. Then 4 mL of ethanol was added to 15 mL of the aqueous solution of graphite oxide. Mechanically stir the obtained mixture for 1 hour and ultrasonically oscillate for 2 hours for dispersion treatment, then put it into a 25mL hydrothermal reaction kettle, place the assembled reaction kettle at a temperature of 140°C for 2 hours, and obtain graphene after cooling down naturally liquid gel. The prepared graphene liquid gel is dried by freeze-drying technology, and then the graphene aerogel is obtained. The obtained graphene airgel was placed in N 2 Calcination at 220°C for 2 h under gas protection for optimization treatment to obtain the final graphene airgel.

[0042] The obtained graphene airgel material is cut into thin slices of about 0.2 mg with a knife and placed in two pieces of nickel foam as...

Embodiment 3

[0044] Firstly, the graphite oxide was ground to refine the particles, and then mixed with deionized water to prepare a graphite oxide aqueous solution with a concentration of 6 mg / mL. Then 4 mL of propanol was added to 25 mL of the aqueous solution of graphite oxide. The obtained mixture was mechanically stirred for 2 hours and ultrasonically oscillated for 4 hours for dispersion treatment, and then put into a 50mL hydrothermal reaction kettle. After the assembled reaction kettle was placed at a temperature of 180°C, it was kept for 2 hours, and graphene was obtained after cooling down naturally. liquid gel. The prepared graphene liquid gel is dried by freeze-drying technology, and then the graphene aerogel is obtained. The obtained graphene airgel was placed in N 2 Calcination at 400°C for 3 h under gas protection was carried out for optimization, and the final graphene airgel was obtained.

[0045] The obtained graphene airgel material is cut into thin slices of about 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com