Graphene/silicon lithium ion battery cathode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., to achieve high specific capacity, simple preparation process, and high cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

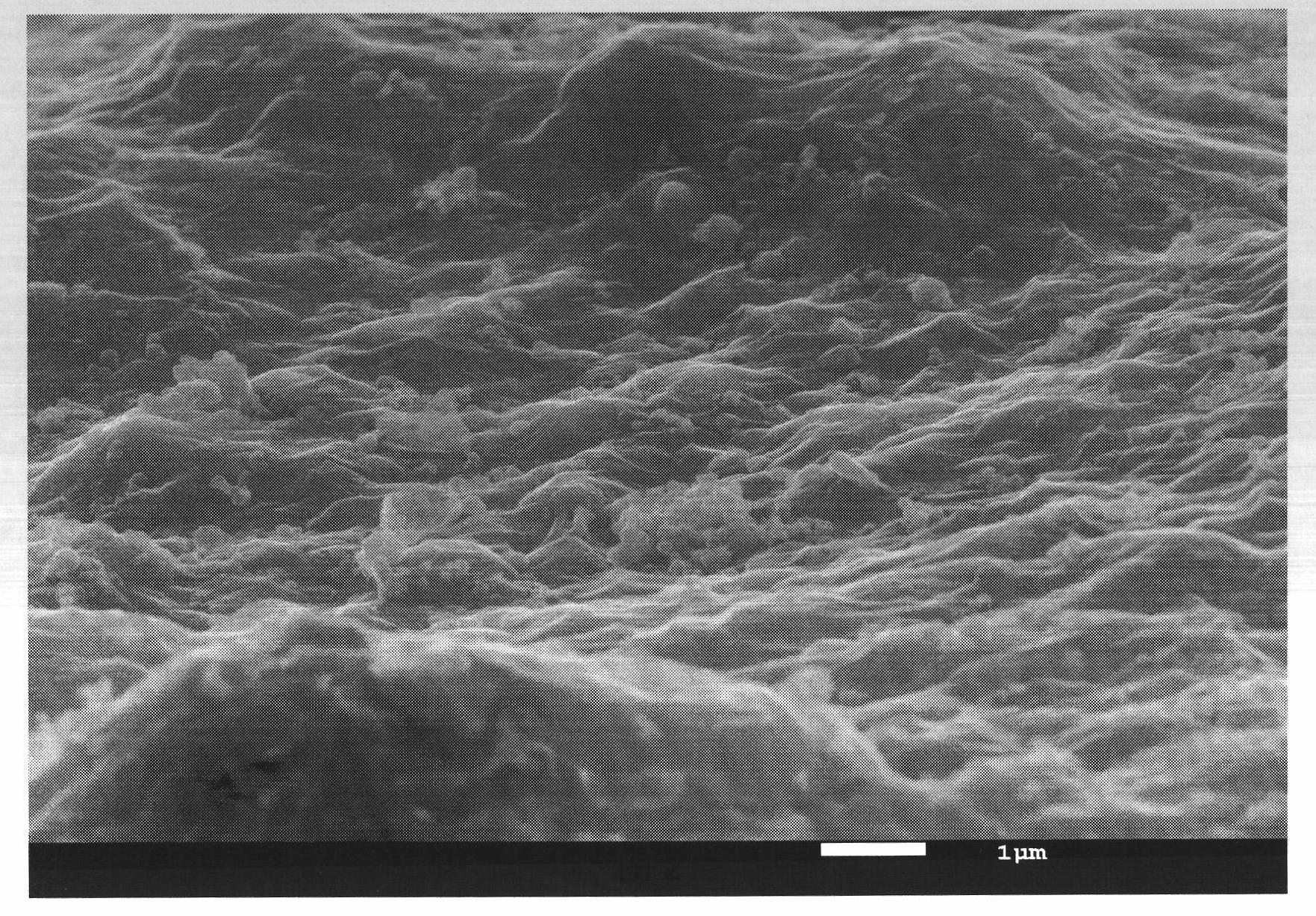

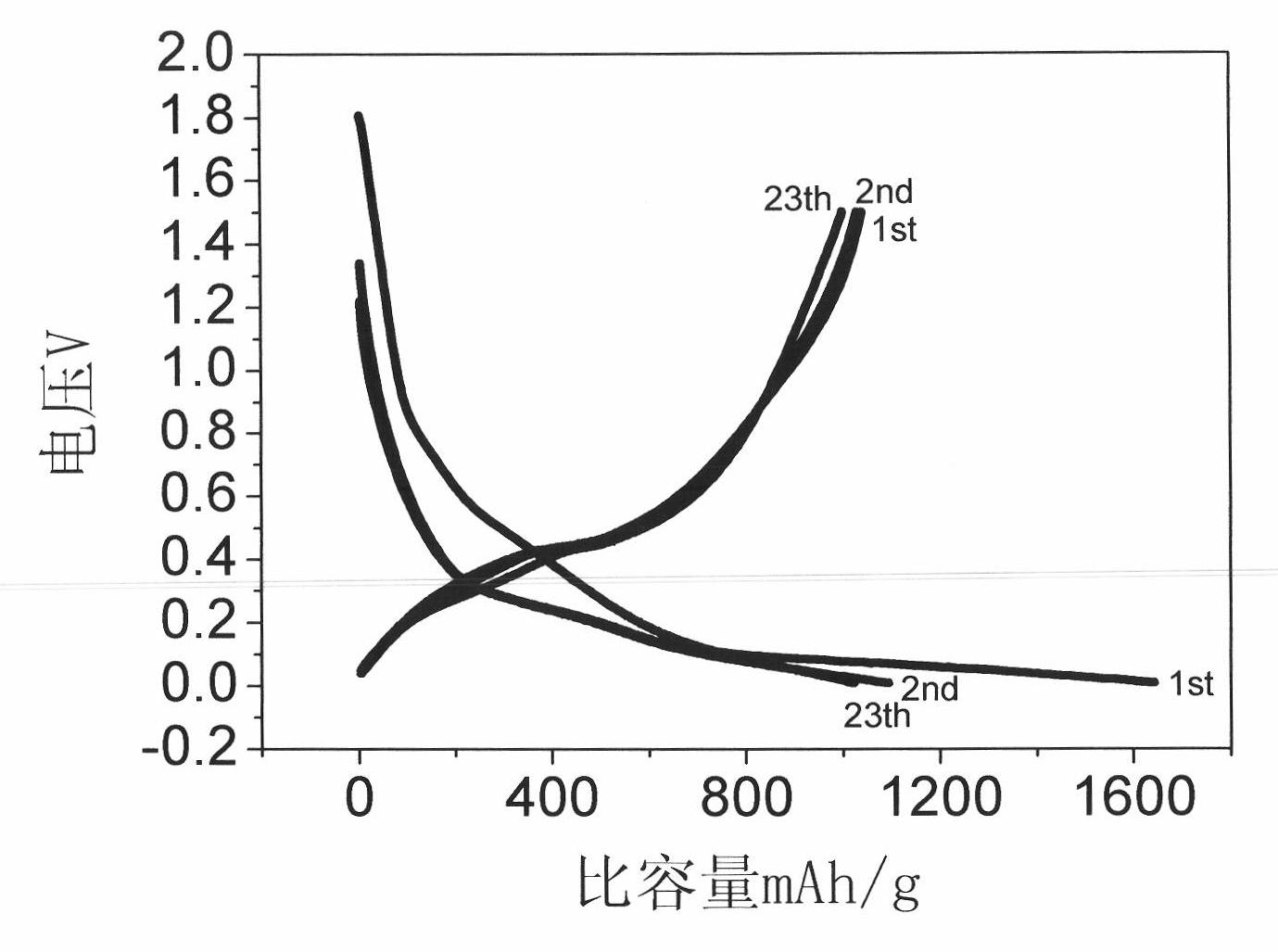

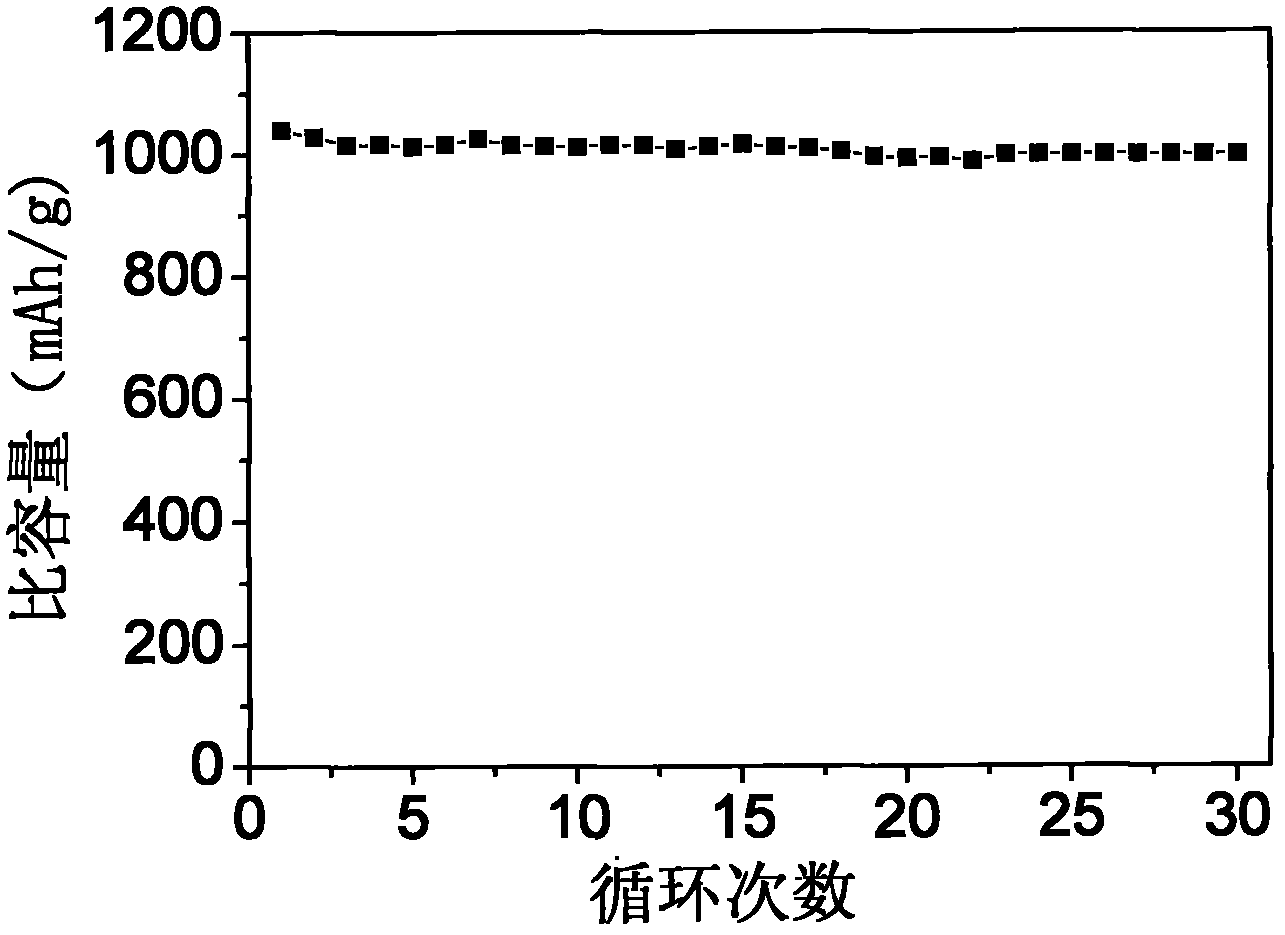

[0024] Example 1: Graphene / Silicon Composite Material I for Lithium-ion Battery Anode Material

[0025] Cool the concentrated sulfuric acid to 0°C, then add graphite and sodium nitrate, stir until uniform, gradually add potassium permanganate, stir for 3h, raise the temperature to 35°C, continue to stir for 0.5h, and then gradually add deionized With water, the temperature was raised to 98°C, reacted at this temperature for 15 minutes, moved to room temperature, added 5% hydrogen peroxide, stirred for 1 hour, then added 1M hydrochloric acid and mixed and stirred. The resulting product was washed with distilled water to neutrality to obtain graphite oxide. The graphite oxide is ultrasonically peeled off for 2 hours to obtain the graphene oxide material. The graphene oxide and silicon powder (~50nm) are mixed and ultrasonically dispersed at a mass ratio of 1:1 to uniformity, and then suction filtered into a cake. The filter cake is 95% Ar and 5% H 2 In a mixed atmosphere, the tempe...

Embodiment 2

[0026] Example 2: Graphene / silicon composite material II for lithium ion battery anode material

[0027] The graphene oxide material was prepared as described in Example 1. The graphene oxide and silicon powder (~50nm) were mixed and ultrasonically dispersed at a mass ratio of 5:1 to uniformity, and then suction filtered into a cake. The filter cake was heated to 90% Ar And 10% H 2 In a mixed atmosphere, the temperature was kept at 700° C. for 3 hours to obtain a graphene / silicon composite material II. The test conditions of the electrode material are as described in Example 1. When charging and discharging at a current density of 50 mA / g, the initial discharge capacity can reach 980 mAh / g, and the capacity after 30 cycles is still 930 mAh / g. When charging and discharging at a high current density of 500mA / g, its specific capacity is 760mAh / g after many cycles.

Embodiment 3

[0028] Example 3: Graphene / silicon composite material III for lithium ion battery anode material

[0029] The graphene oxide material was prepared as described in Example 1. The graphene oxide and silicon powder (~50nm) were mixed and ultrasonically dispersed at a mass ratio of 10:1 to uniformity, and then suction filtered into a cake. The filter cake was heated to 90% Ar And 10% H 2 In a mixed atmosphere, the temperature is kept at 700° C. for 3 hours to obtain the graphene / silicon composite material III. The test conditions of the electrode material are as described in Example 1. When charging and discharging at a current density of 50 mA / g, the initial discharge capacity can reach 880 mAh / g, and the capacity after 30 cycles is still 850 mAh / g. When charging and discharging at a high current density of 500mA / g, its specific capacity is 680mAh / g after many cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com