A multi-degree-of-freedom low-frequency vibration isolator based on the coupling of vibration mode and pendulum mode

A modal coupling and vibration modal technology, applied in springs/shock absorbers, magnetic springs, mechanical equipment, etc., can solve problems such as the inability to meet multi-degree-of-freedom low-frequency vibration suppression, avoid interference caused by magnetic fields, and achieve high reliability. , the effect of reducing the natural frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

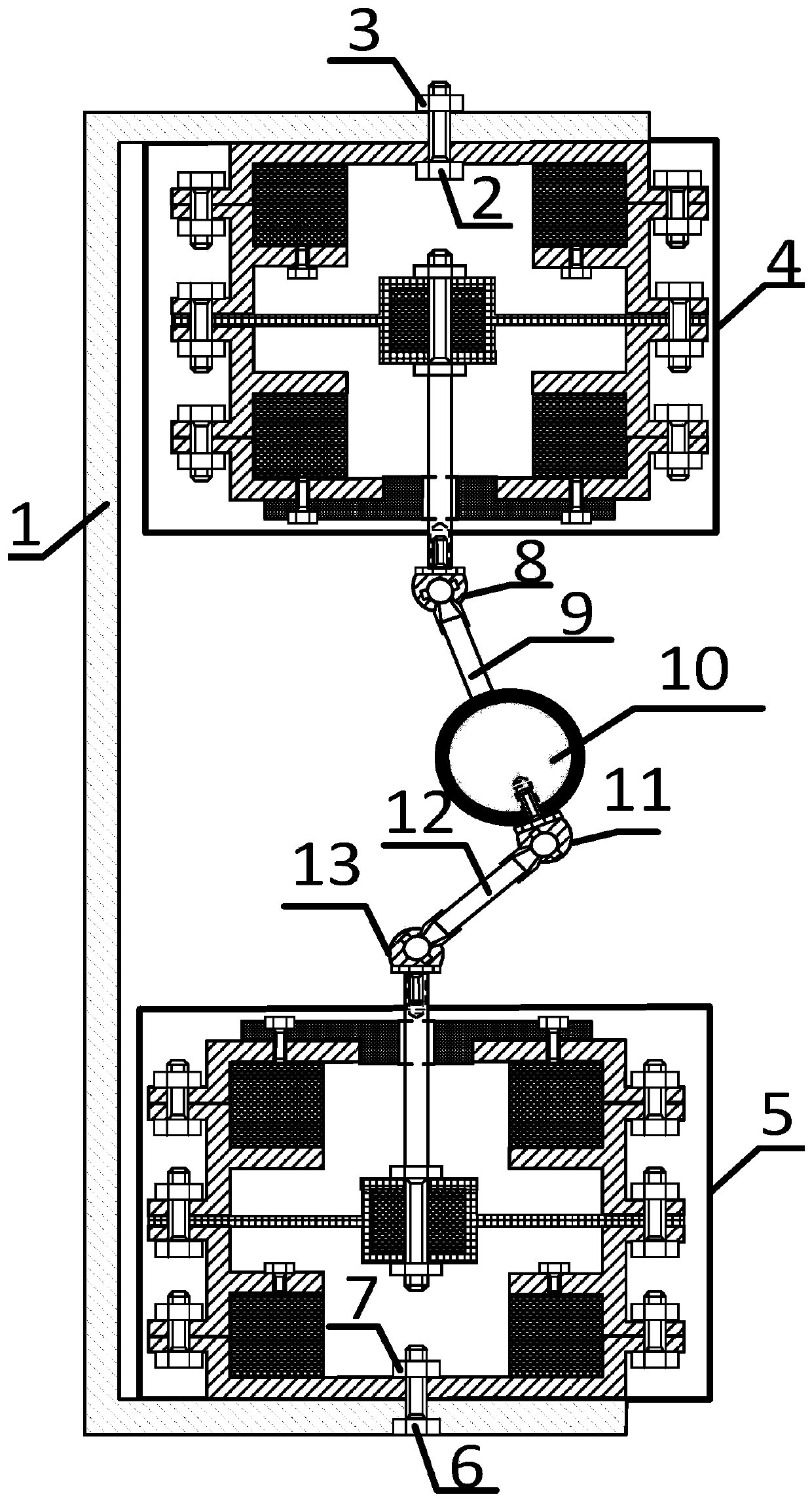

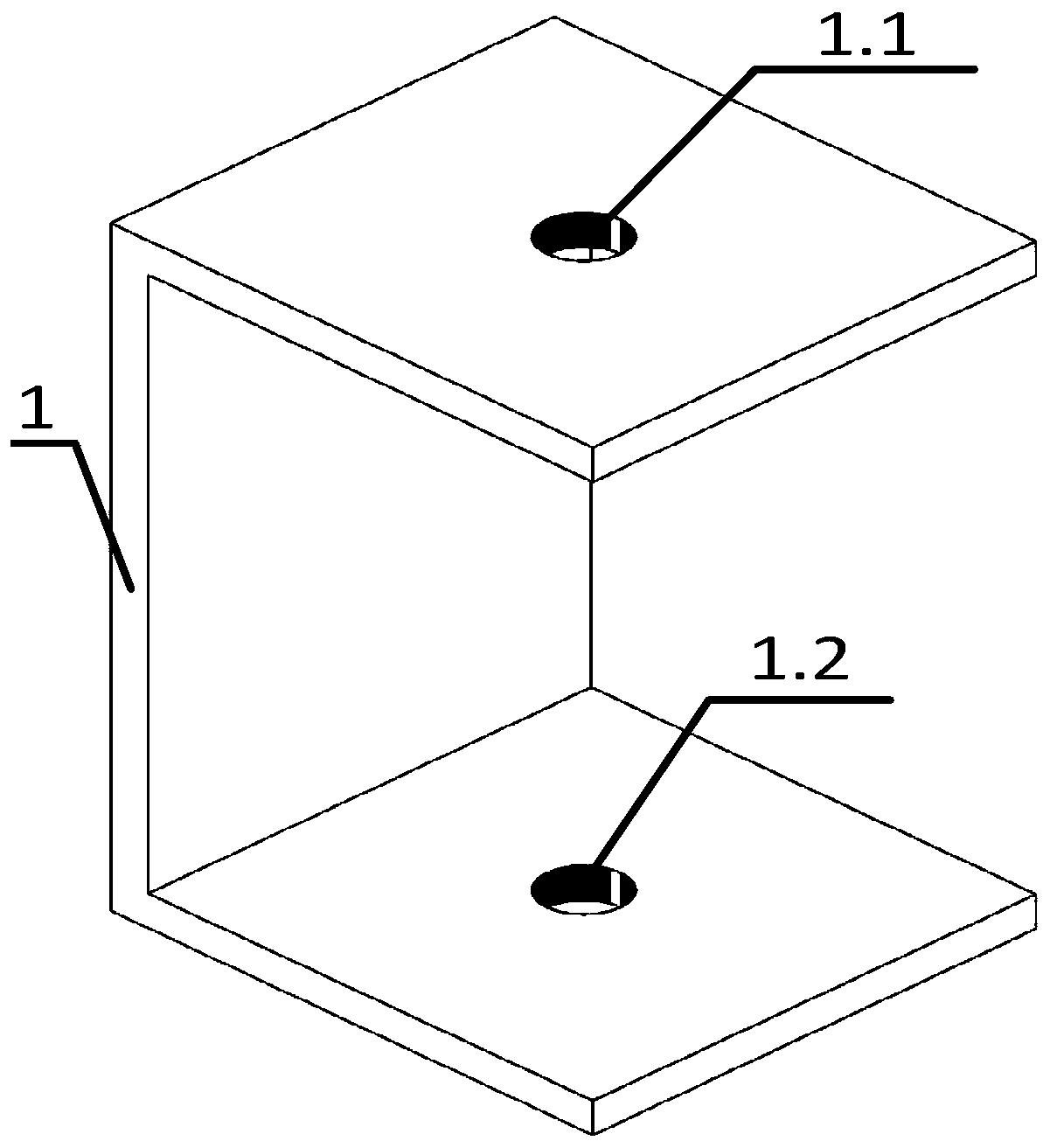

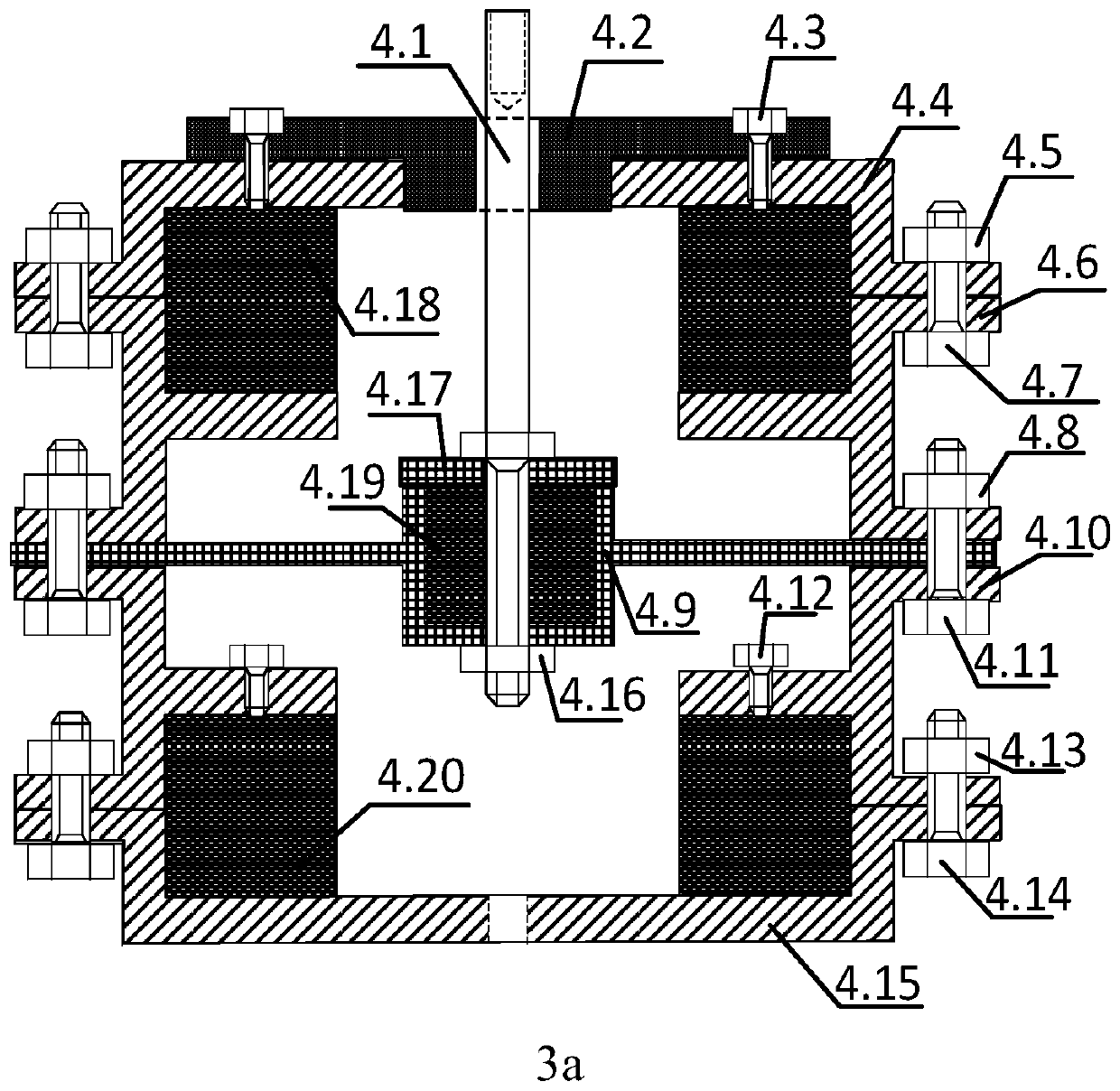

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention is a multi-degree-of-freedom low-frequency vibration isolator based on vibration mode and pendulum mode coupling, including a support frame 1, a first high static-low dynamic stiffness vibration isolator 4 installed symmetrically up and down on the support frame 1 and The second high static-low dynamic stiffness vibration isolator 5; the first high static-low dynamic stiffness vibration isolator 4 passes through the first bottom hole 4.15-1 and the upper end of the support rod frame 1 through the first bolt 2 The hole 1.1 is connected and fastened with the first nut 3; the second high static-low dynamic stiffness vibration isolator 5 passes through the second bottom hole 5.15-1 and the lower end through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com