Dynamic calibration method for high-frequency force balance

A calibration method and balance technology, applied in aerodynamic tests, machine/structural component testing, instruments, etc., can solve problems affecting signal separation effect, rough approximation, modal damping ratio identification error, etc., and achieve reliable separation effect , good power calibration effect, and simplified test steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

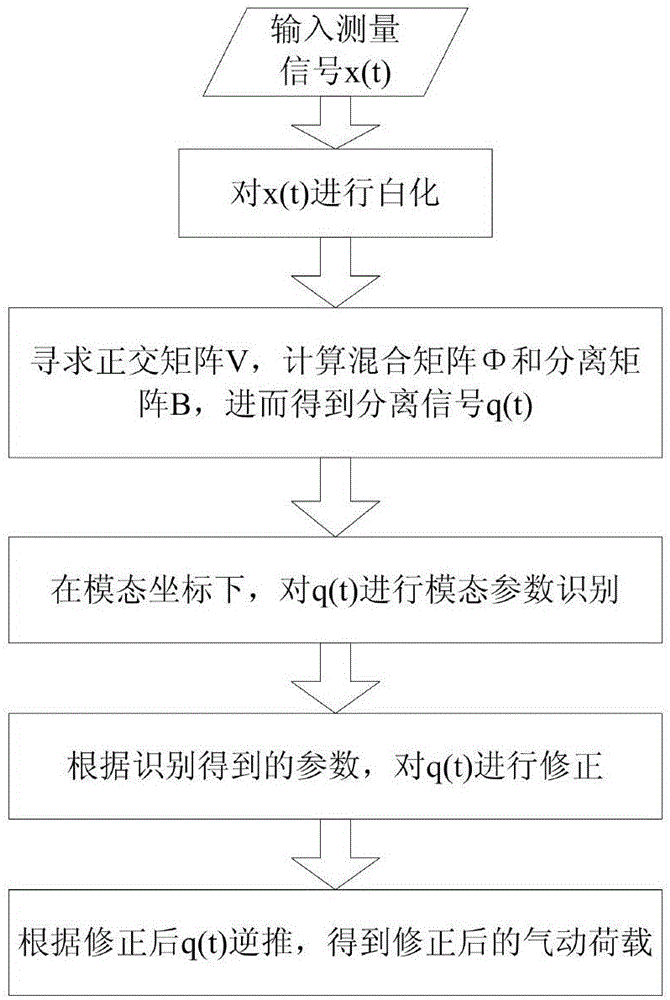

[0069] A dynamic calibration method for high-frequency base force balances for proportional damping, such as figure 1 , including the following steps:

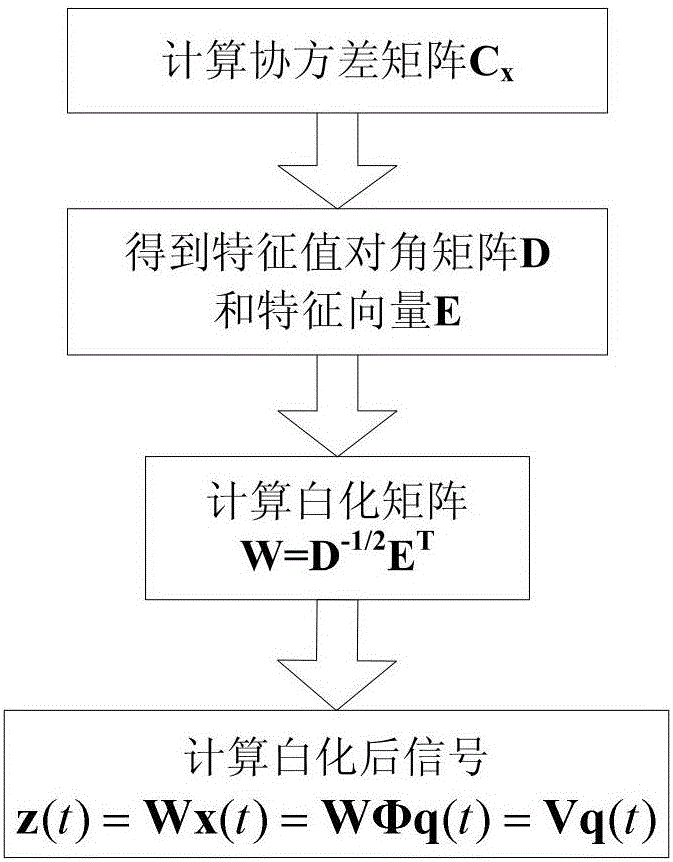

[0070] Step 1: Whiten the measured signal x(t) to obtain the whitened signal z(t);

[0071] Step 2: Seek the orthogonal matrix V so that z(t)=Vq(t), and then calculate the separation signal q(t);

[0072] Step 3: Under the modal coordinates, identify the natural frequency and modal damping ratio of the separated signal;

[0073] Step 4: Correct the separation signal according to the identified parameters;

[0074] Step 5: Inversely infer from the corrected separation signal to obtain the corrected aerodynamic load.

[0075] Specifically, let the mixed model be

[0076] x(t)=Φq(t) (1)

[0077] where x(t), Φ and q(t) are the model base load (overturning moment, torque and shear force), mixing matrix and source signal (ie, modal response signal) measured by HFFB, respectively. The source signal q(t) obtains the observed sig...

Embodiment 2

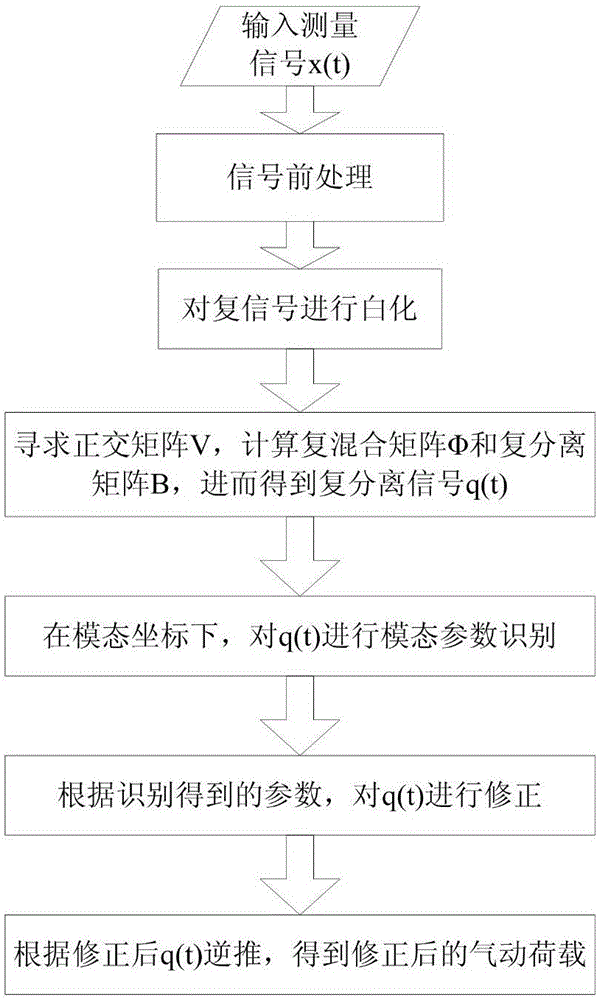

[0145] A method for dynamic calibration of high-frequency base force balances for non-proportional damping, such as figure 2 , including the following steps:

[0146] Step 1: Signal preprocessing: shift the phase of the measurement signal x(t) by 90° to get x 90 (t), and then assemble the two into a complex signal;

[0147] Step 2: Whiten the assembled complex signal;

[0148] Step 3: Find the orthogonal matrix V, calculate the complex mixing matrix Φ and the complex separation matrix B, and then obtain the complex separation signal q(t);

[0149] Step 4: Under the modal coordinates, perform modal parameter identification on the complex separation signal;

[0150] Step 5: Correct the complex separation signal according to the identified parameters;

[0151] Step 6: Inversely infer from the corrected complex separation signal to obtain the corrected aerodynamic load.

[0152] For non-proportional damping, some improvements need to be made on the basis of the method in Exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com