Indoor testing device and method for solidified residual soil by virtue of microorganism grouting technique

An indoor test and residual soil technology, which is used in soil material testing, material inspection products, preparation of test samples, etc., can solve the problems of unevenness, insufficient precision, waste of resources, etc. The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment the method of the present invention is described in further detail. It should be noted that the protection scope of the present invention shall include but not be limited to the technical content disclosed in this embodiment.

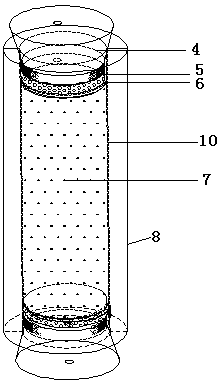

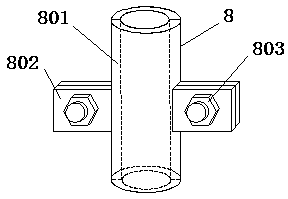

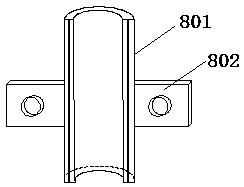

[0028] The indoor test device for the microbial grouting technology of the present invention to consolidate residual soil comprises an iron stand 14 and a stainless steel split mold 8 clamped and fixed on the iron stand, wherein the stainless steel split mold 8 is filled with residual soil particles 7, and the stainless steel split mold 8 A coarse sand cushion 6 and a gauze cushion 5 are arranged in the split mold 8 above and below the residual soil particles, and the stainless steel split mold ports are respectively plugged with an upper single-hole rubber plug 4 and a lower single-hole rubber plug 15 , the lower single-hole rubber plug penetrates the lower drainage tube 11, the lower drainage tube is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com