Mechanical arm pose precision testing system

A technology of precision testing and manipulators, applied in measuring devices, instruments, optical devices, etc., can solve problems such as immature technology, short action time, incomplete gravity compensation, etc., and achieve simple test steps, reliable test data, and easy implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

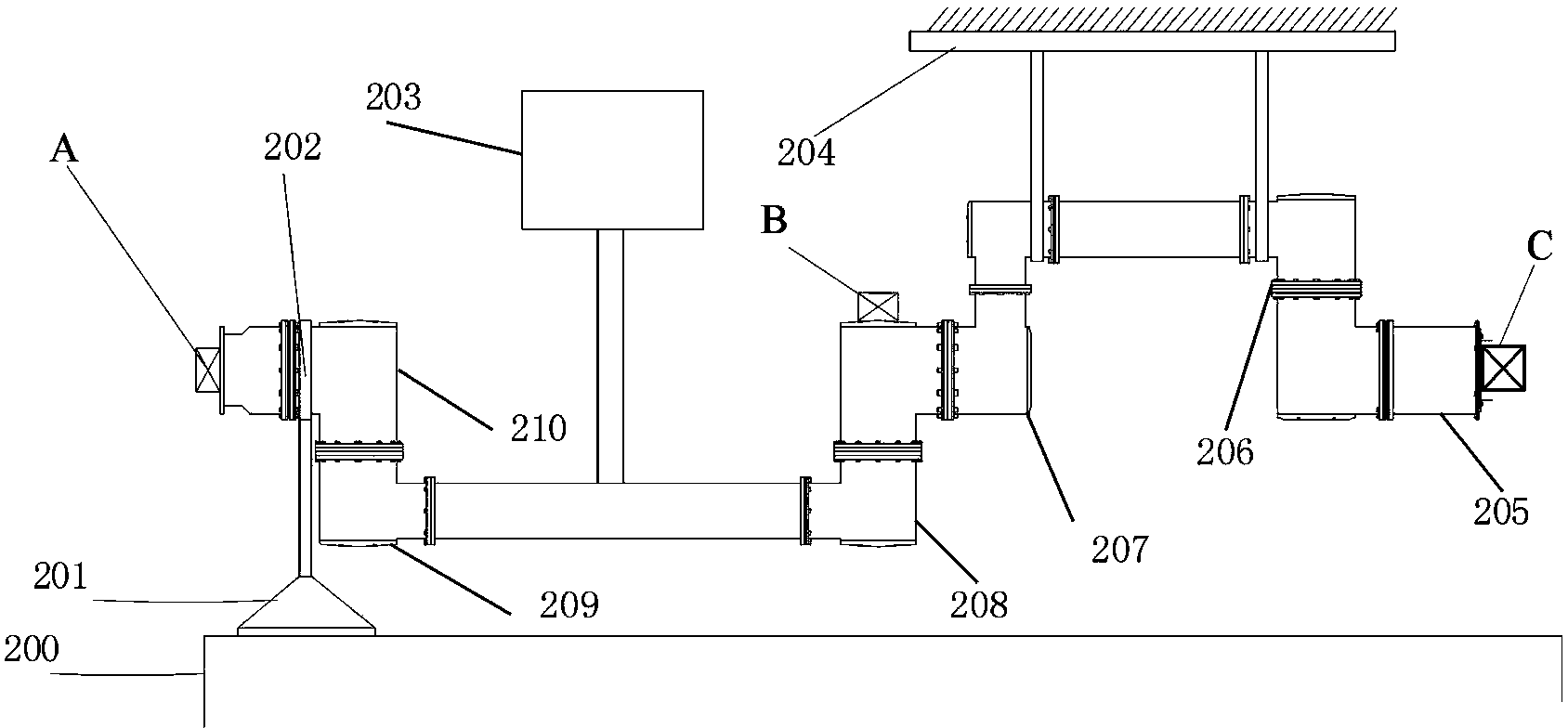

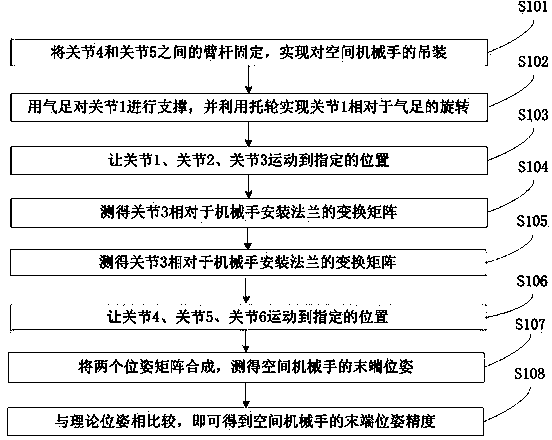

[0028] exist figure 1 Among them, the manipulator posture accuracy test system includes air floating platform 200, air foot 201, support wheel 202, air pump, manipulator support frame 204, balance weight 203, 6D laser tracker, arm bar, first joint 205, second The second joint 206, the third joint 207, the fourth joint 208, the fifth joint 209, and the sixth joint 210; the air foot 201 is an air jet port, and the air pump is used to provide aerodynamic force;

[0029] The air flotation platform is used to exert reaction force on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com