Quantitative evaluation test method for coal core damage

A technology of quantitative evaluation and testing method, applied in the quantitative evaluation and testing of coal core damage, testing the field of coal core damage, can solve the problems that X-ray and CT measurement cannot be carried out in real time, complicated operation and high cost, and achieve accurate and intuitive calculation methods. Simple equipment and simple test steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

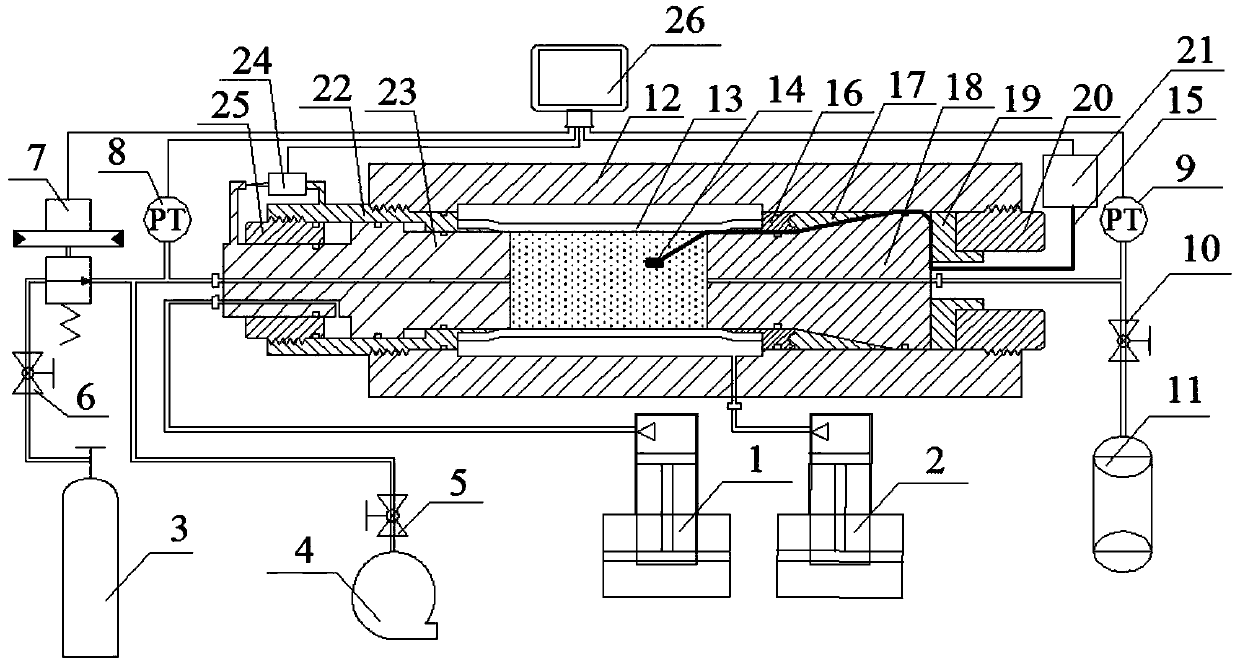

[0091] A quantitative evaluation test method for coal core damage, the test steps in creep damage are as follows:

[0092]① Process the coal rock sample into a cylindrical coal core with a diameter of 50 mm and a length of 100 mm; put the coal core in an oven at 45°C for 24 hours for drying; select four flat areas on the outer surface of the core of the coal core to avoid the existence of micro-cracks Grind the position to be pasted with sandpaper, clean up the floating dust, apply the adhesive, cover the strain gauge 14, press the strain gauge 14, and paste the remaining strain gauges 14 in sequence after the adhesive solidifies; welding;

[0093] ② Put the coal core into the rubber sleeve 13 and place it in the pressure chamber 12; pass the strain gauge lead wire 15 through the plug II 18 to ensure that the strain gauge lead wire 15 is not bent; connect the strain gauge lead wire 15 to the strain collector 21 , connecting the strain collector 21 and the displacement sensor ...

Embodiment 2

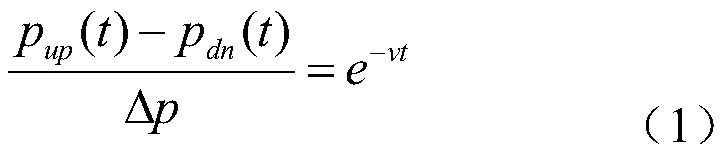

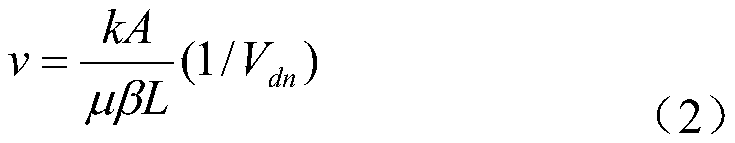

[0124] A quantitative evaluation test method for coal core damage, the test steps in the cycle pulse air pressure anti-reflection are as follows:

[0125] ① Process the coal rock sample into a cylindrical coal core with a diameter of 50 mm and a length of 100 mm; put the coal core in an oven at 45°C for 24 hours for drying; select four flat areas on the outer surface of the core of the coal core to avoid the existence of micro-cracks Grind the position to be pasted with sandpaper, clean up the floating dust, apply the adhesive, cover the strain gauge 14, press the strain gauge 14, and paste the remaining strain gauges 14 in sequence after the adhesive solidifies; welding;

[0126] ② Put the coal core into the rubber sleeve 13 and place it in the pressure chamber 12; pass the strain gauge lead wire 15 through the plug II 18 to ensure that the strain gauge lead wire 15 is not bent; connect the strain gauge lead wire 15 to the strain collector 21 , connecting the strain collecto...

Embodiment 3

[0161] A quantitative evaluation test method for coal core damage, the test steps of which are damaged by triaxial stress loading are as follows:

[0162] ① Process the coal rock sample into a cylindrical coal core with a diameter of 50 mm and a length of 100 mm; put the coal core in an oven at 45°C for 24 hours for drying; select four flat areas on the outer surface of the core of the coal core to avoid the existence of micro-cracks Grind the position to be pasted with sandpaper, clean up the floating dust, apply the adhesive, cover the strain gauge 14, press the strain gauge 14, and paste the remaining strain gauges 14 in sequence after the adhesive solidifies; welding;

[0163] ② Put the coal core into the rubber sleeve 13 and place it in the pressure chamber 12; pass the strain gauge lead wire 15 through the plug II 18 to ensure that the strain gauge lead wire 15 is not bent; connect the strain gauge lead wire 15 to the strain collector 21 , connecting the strain collecto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com