Numerical control tool system for providing vibration reduction by utilizing microcosmic friction and mass distribution

A technology of mass distribution and tool system, applied in the direction of tools, milling cutters, drilling tool accessories, etc. for lathes, it can solve the problems of changing friction phenomenon, unable to provide shock absorption function stably, and optimize static stiffness and dynamic stiffness. , Easy to operate, improve the effect of shock absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

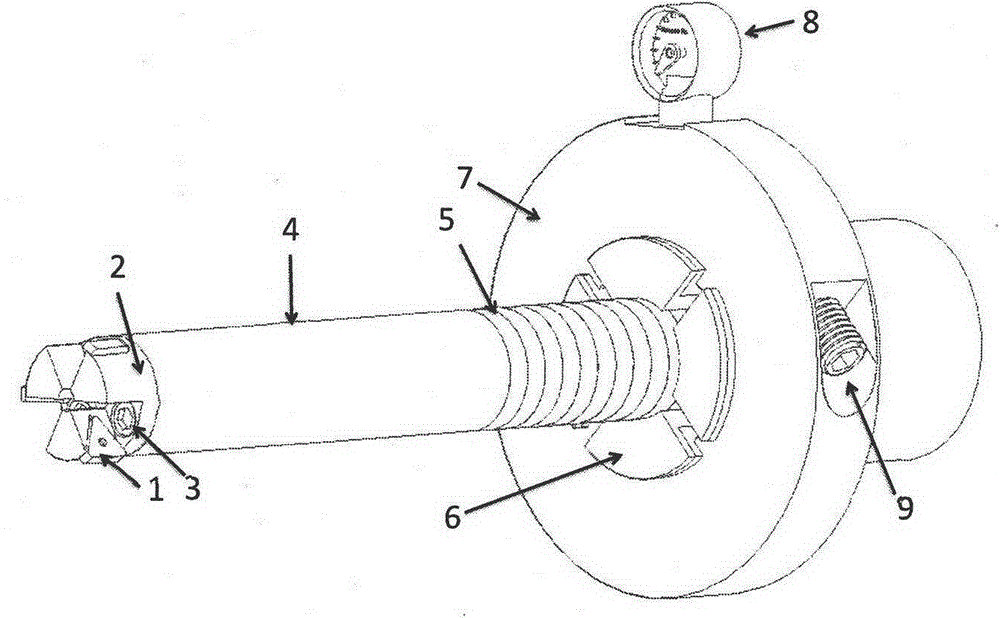

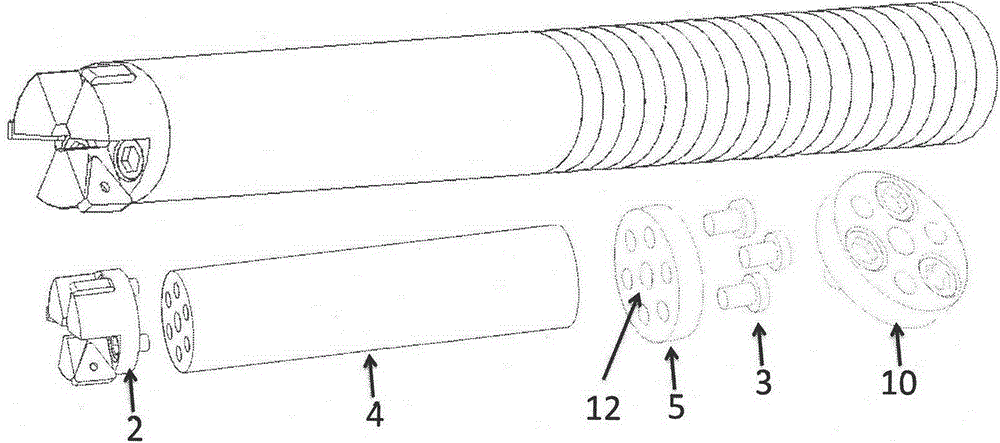

[0022] Embodiment of the present invention: adopt the present invention, a numerically controlled cutting tool system that utilizes microscopic friction and mass distribution to provide shock absorption. The inner and outer walls of the member 7 expand and deform. The expansion and deformation of the inner wall of the hydraulic fastener 7 squeezes the powerful spring 6, thereby forming the clamping and fixing of the knife bar structure. The pressure of the hydraulic grease 13 is indicated by the hydraulic gauge 8, and a suitable hydraulic grease pressure is selected according to different cutting forces.

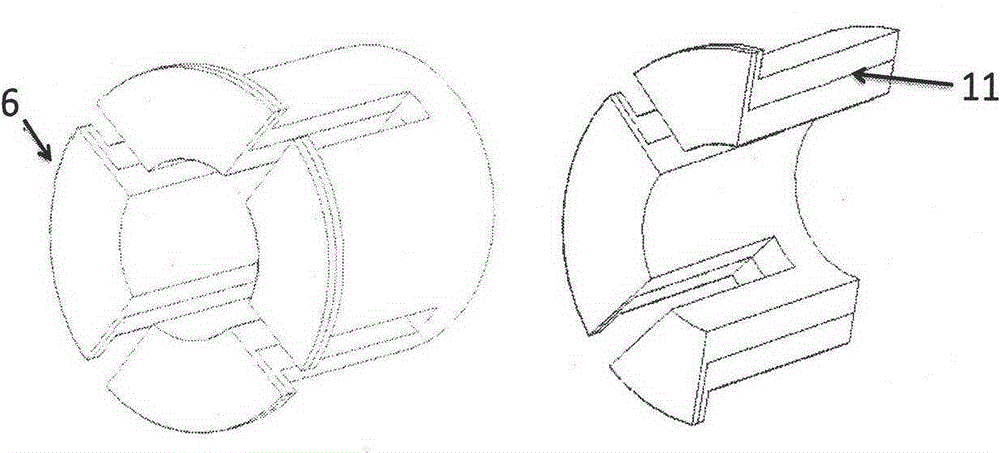

[0023] The strong spring 6 is made up of several thin-walled parts, and the thin-walled parts assembly joint surface 11 is formed between several thin-walled parts. By adjusting the expansion deformation of the inner wall of the hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com