Experimental device and method for researching thermo-acoustic instability longitudinal and tangential mode coupling mechanism

A modal coupling and experimental device technology, applied in the direction of internal combustion engine testing and other directions, can solve the problems of high cost, complex structure, difficulty in revealing the longitudinal and tangential modal coupling mechanism of the annular combustion chamber, etc., and achieves low cost, convenient processing, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

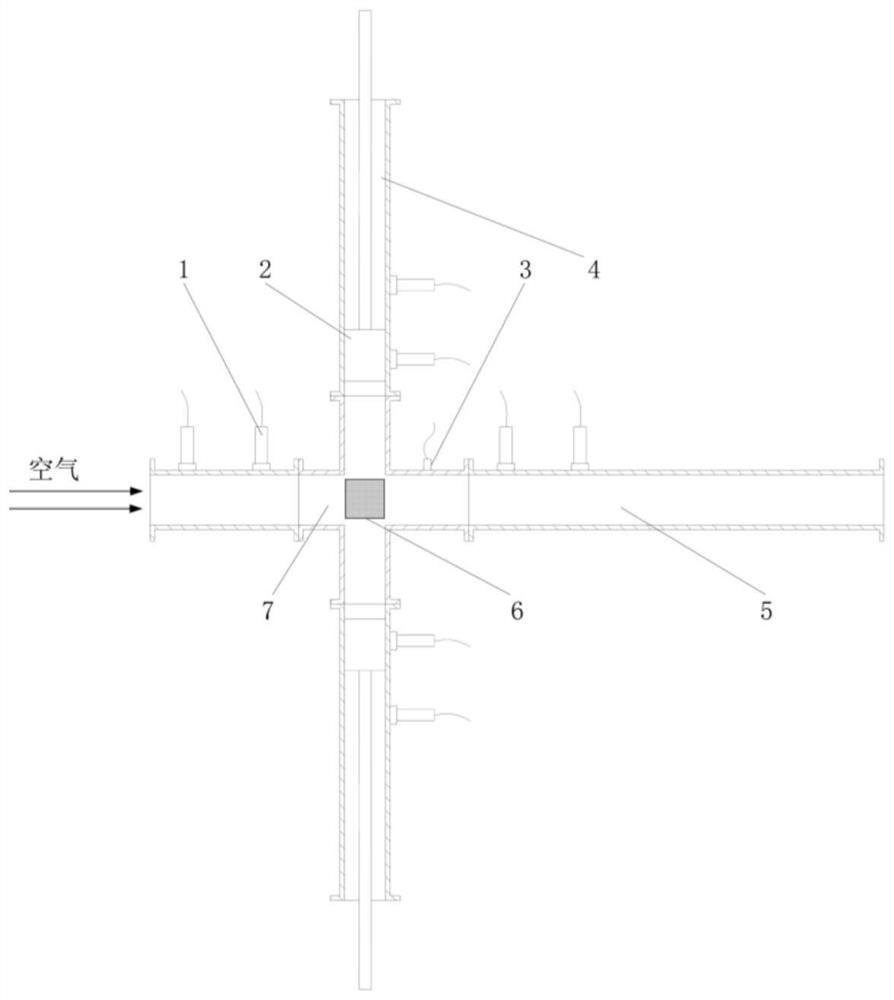

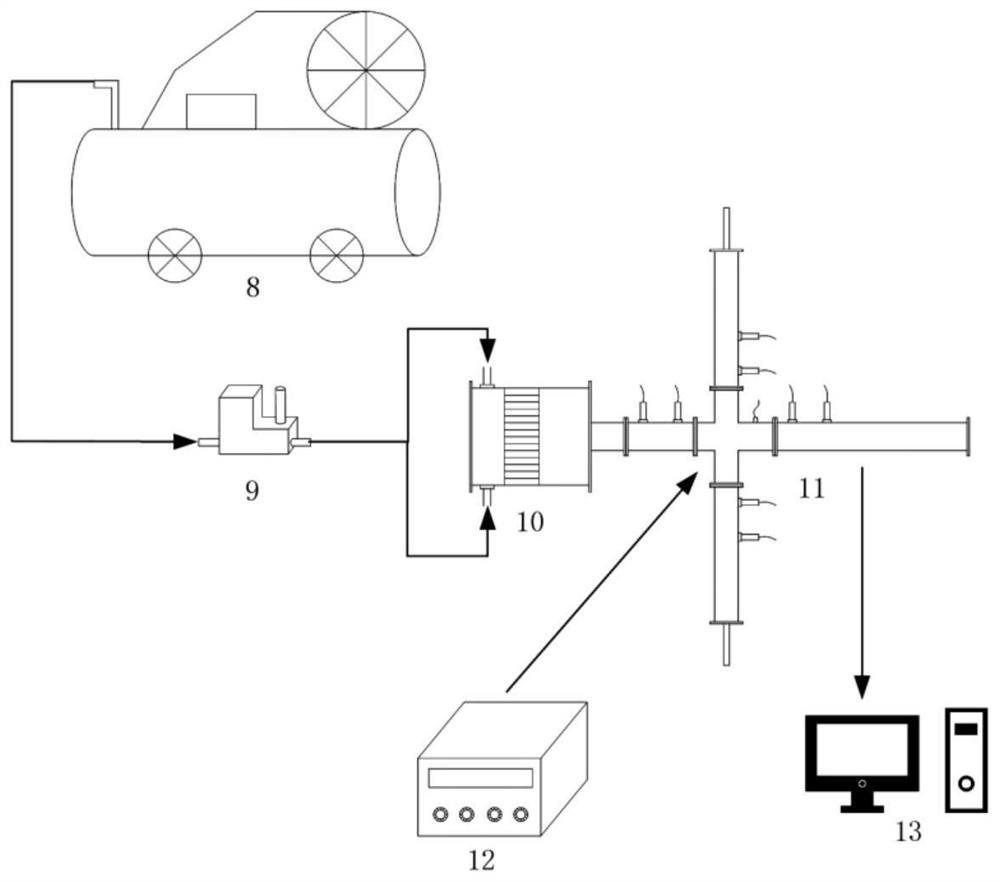

[0025] In this example, an experimental platform for research on the coupling of longitudinal and tangential modes of thermoacoustic instability is built, such as figure 2 As shown, the gas output by the air compressor 8 passes through the gas mass flowmeter 9 and the rectifying chamber 10 and then enters the cross-shaped combustion chamber 11. The electric heater 6 in the combustion chamber is powered by a DC stabilized power supply 12, and the data of the pressure sensor 1 It is finally summarized on the computer 13. By changing the position of the tangential piston 2 and adding the longitudinal square tube 5 to achieve different lengths of the combustion chamber, by changing the average air flow rate and the power of the electric heater, the coupling mechanism of thermoacoustic instability longitudinal and tangential modes was studied.

[0026] In this embodiment, the inner and outer wall sections of the longitudinal square tube are squares of 68×68 and 80×80 respectively,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com