Fastening system capable of compensating tolerance

A fastening and tolerance technology, applied in the field of fastening structures that compensate for tolerances, can solve the problems of difficult control and large assembly size errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

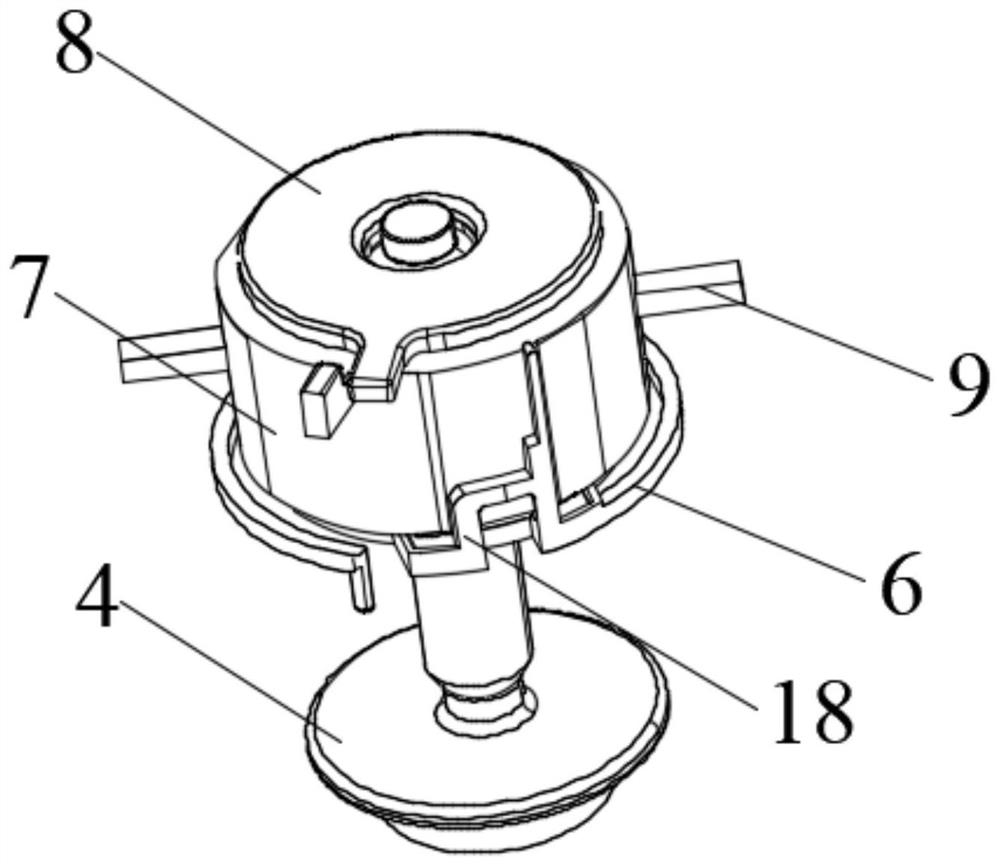

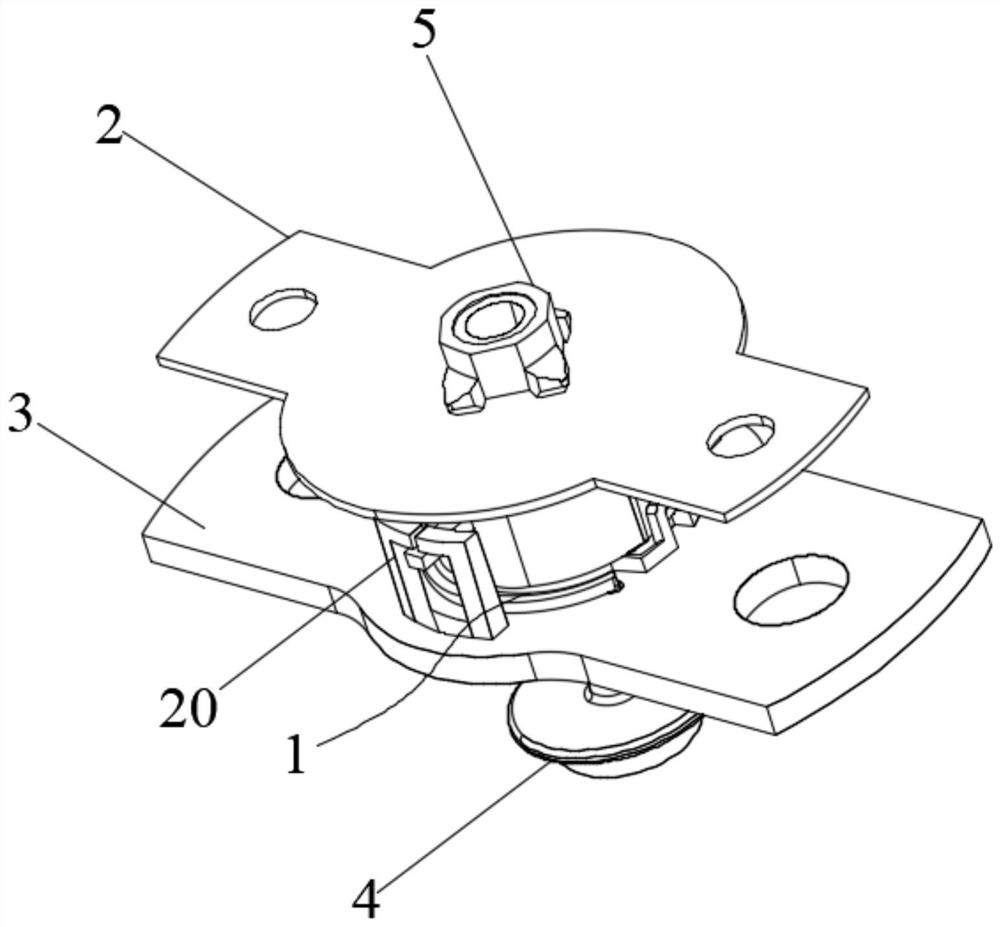

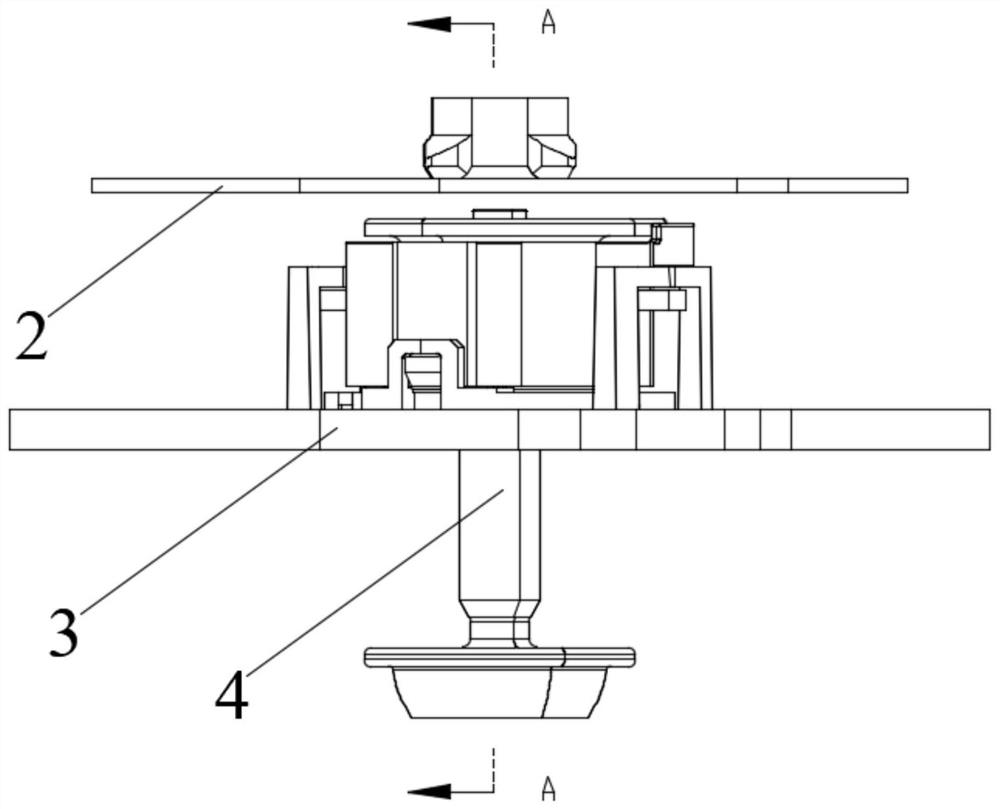

[0026] Such as Figure 1 to Figure 9 As shown, the present invention is a fastening structure for compensating tolerances, which includes a fastening system 1, the fastening system 1 is assembled between the mounting sheet metal 2 and the fastened workpiece 3, and the mounting bolts 4 are sequentially screwed into the fastened workpiece 3. Fastening system 1. After the sheet metal 2 is installed, it is locked by the projection welding nut 5. The fastening system 1 includes a limit piece 6, an installation connection piece 7, and an adjustment piece 8. The limit piece 6 is limited and assembled on the fastened On the workpiece 3, the installation connector 7 is assembled on the limiter 6, the adjustment member 8 is screwed into the installation connector 7, and the installation bolt 4 passes through the limiter 6 and the adjustment member successively after being penetrated by the fastened workpiece 3 8. To install the sheet metal 2, the limiter 6 is provided with a first clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com