Flutter stability domain modeling approach for face cutting process

A modeling method and plane cutting technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems that affect the processing quality of parts and aggravate tool wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

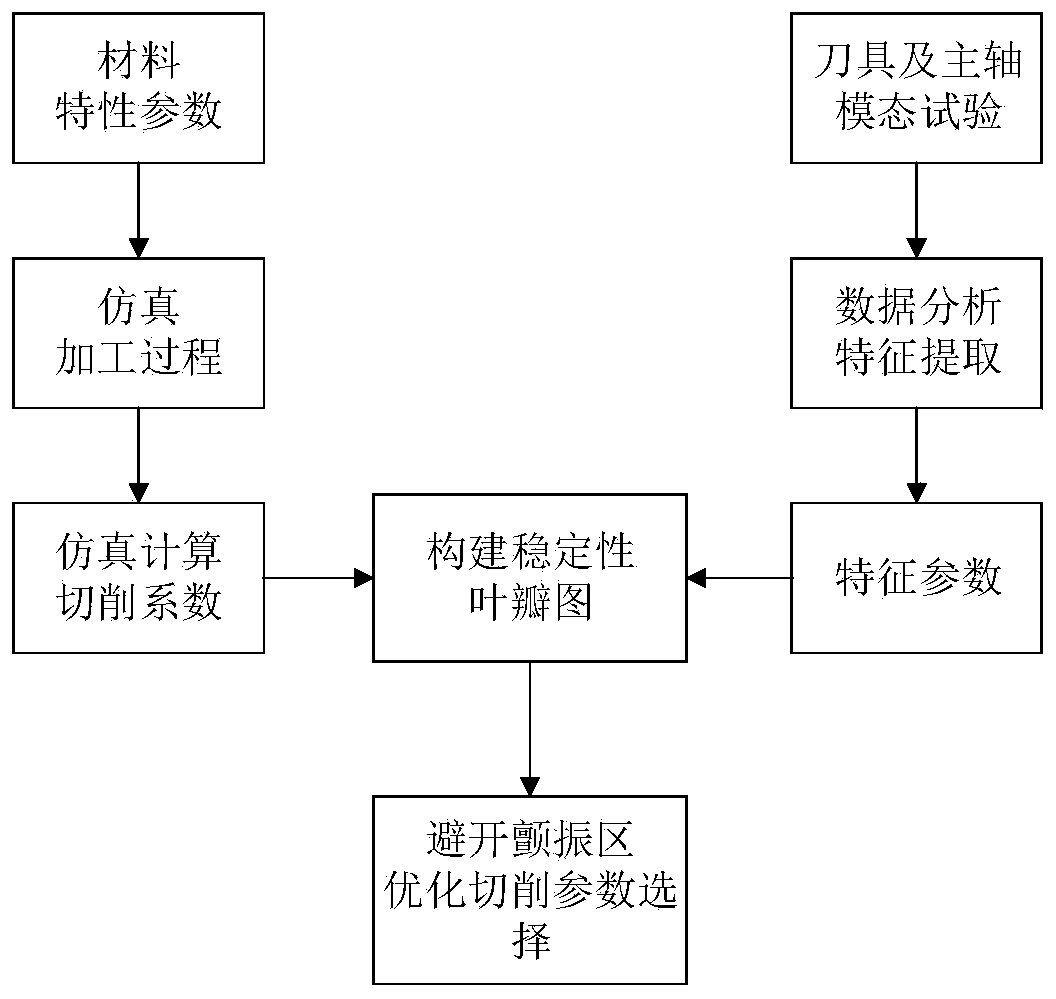

[0053] Such as figure 1 and figure 2 As shown, among them, the material characteristic parameters include the material of the workpiece and the cutting tool, calculate the total cutting force in the cutting process, and use the regression to fit the cutting coefficient. Combined with the characteristic parameters obtained from the modal experiment, the stability lobe diagram is drawn, which is used to select the cutting parameters, including the number of revolutions, depth of cut and so on.

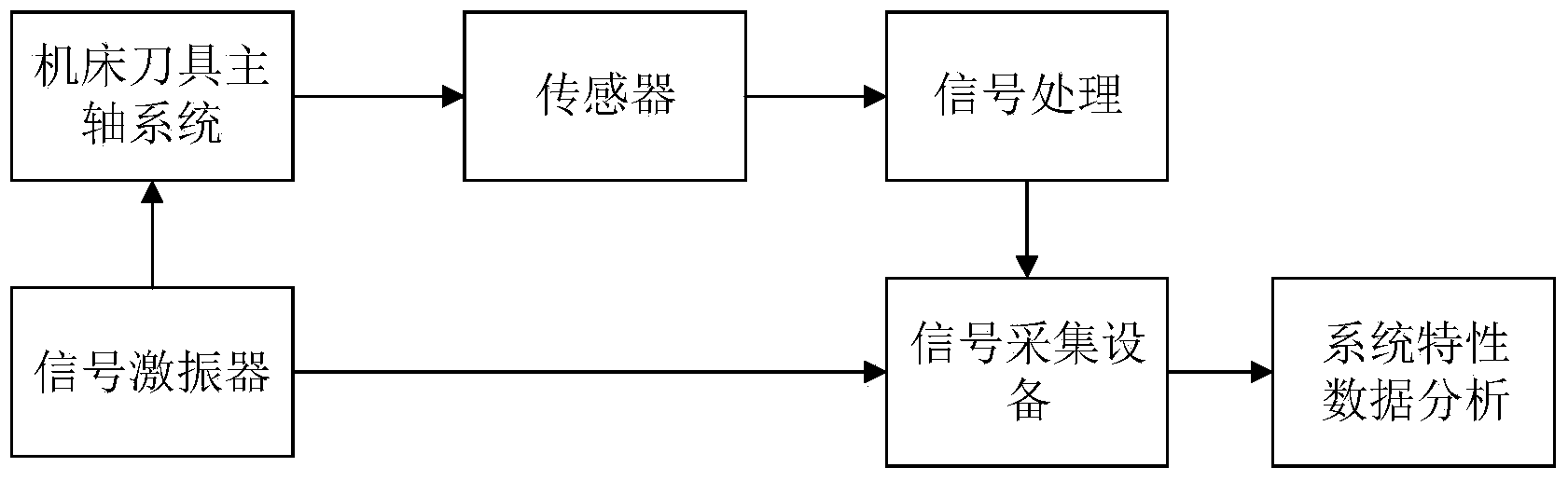

[0054] Use the exciter (hammer or exciter) to excite the tool system of the machine tool spindle, process the excitation signal and the collected response signal to the signal acquisition device, use FFT transformation and model fitting, and analyze it by computer The characteristic parameters of the system, including multi-order natural fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com