Method for executing layout optimization on model analysis measurable nodes of numerical control machining equipment

A technology of mechanical processing and experimental modal analysis, applied in the direction of adaptive control, general control system, control/adjustment system, etc., can solve the problem that the optimization of measuring point layout cannot be fully and effectively realized, and the measuring point cannot meet the requirements of identifying the mode shape To optimize the number of measuring points and the location of measuring points, improve test efficiency, and overcome low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be specifically described below in conjunction with the accompanying drawings.

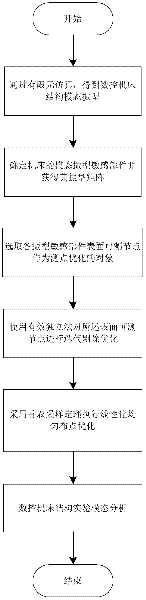

[0027] figure 1 It is a flow block diagram of a method for performing layout optimization on experimental modal analysis measurement points of a numerically controlled machine tool according to the present invention. Such as figure 1 As shown in, the following will take the analysis of the structural experimental modal analysis of the XHK5140 vertical CNC machining center as an example to specifically illustrate the process steps of the present invention:

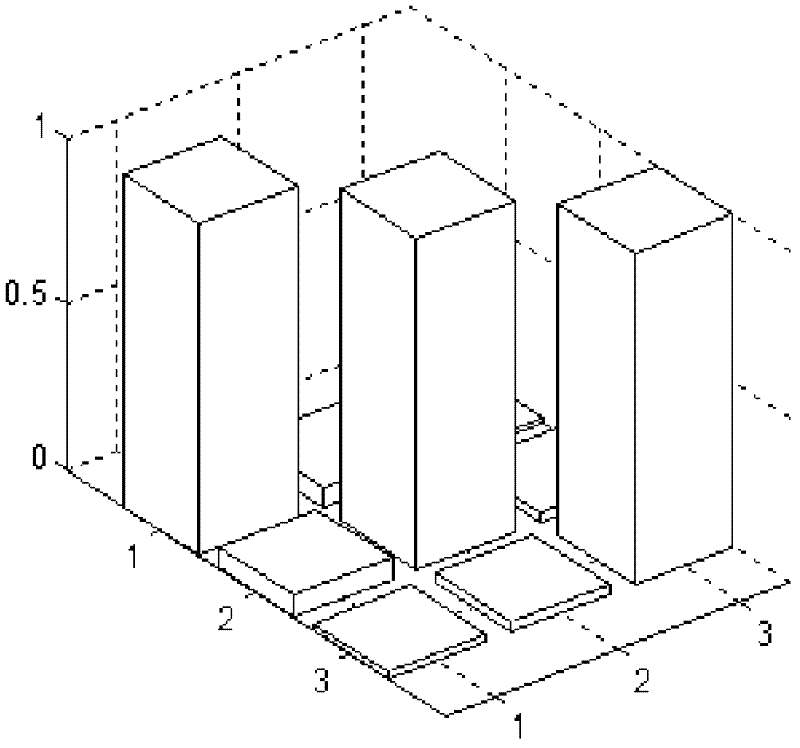

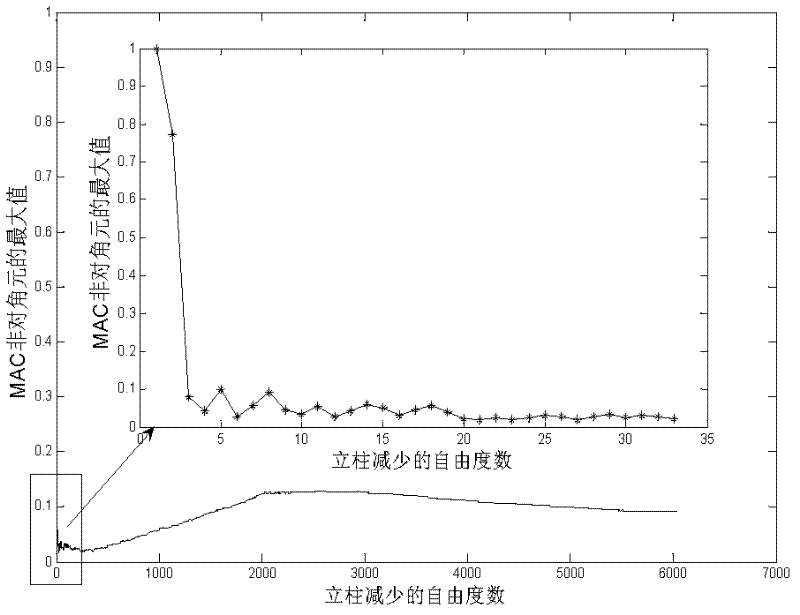

[0028] Firstly, through finite element simulation, the overall structural mode shape and corresponding mode shape matrix are obtained. The specific process is as follows: the size of the XHK5140 CNC machining center is obtained through actual measurement, and then the 3D modeling is carried out by the computer in the finite element analysis software MSC Patran, and finally the mesh division and modal analysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com