Waist-form tunnel boring machine

A tunnel boring machine and waist-shaped technology, which can be used in tunnels, mining equipment, earthwork drilling and mining, etc., and can solve problems such as inability to carry out full-section excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

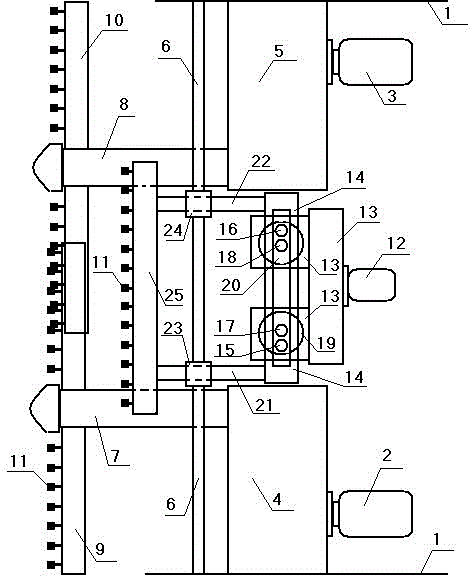

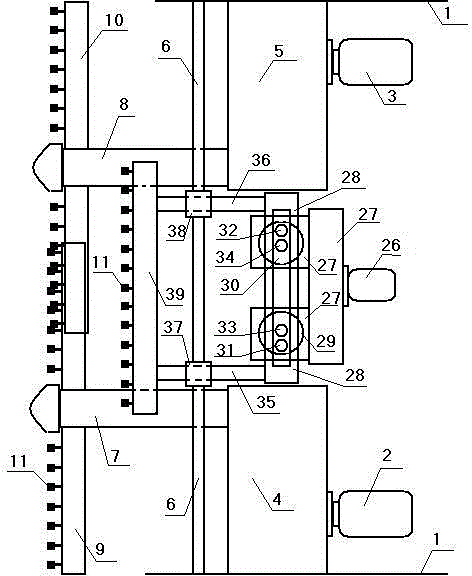

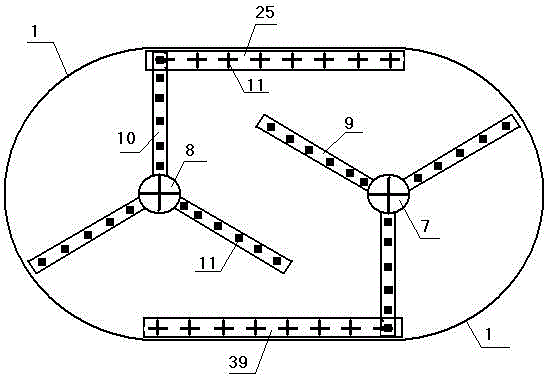

[0013] The accompanying drawing is a specific embodiment of the present invention, which is provided side by side with a first main cutter head 9 and a second main cutter head 10, and the first main cutter head is driven by a first motor 2 through a first power box 4 and a first main shaft 7 Driven to rotate, the second main cutter head is driven to rotate by the second motor 3 through the second power box 5 and the second main shaft 8. The top of the first main shaft and the second main shaft is provided with a first impact tool bar 25, and the right side of the first impact tool bar A first square shaft 21 and a second square shaft 22 are fixed, the right end of the first square shaft and the right end of the second square shaft are respectively fixed on the front end and the rear end of the first rectangular plate 14, and a rectangular hole is arranged in the middle of the first rectangular plate , the first pin shaft 15 is inserted into the rectangular hole, the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com