Device for online detection for stress of hobbing cutter of tunnel boring machine

A roadheader, full-section technology, applied in the direction of measuring force components, etc., can solve the problem of easy damage of the hob, achieve the effect of prolonging the service life and ensuring the driving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

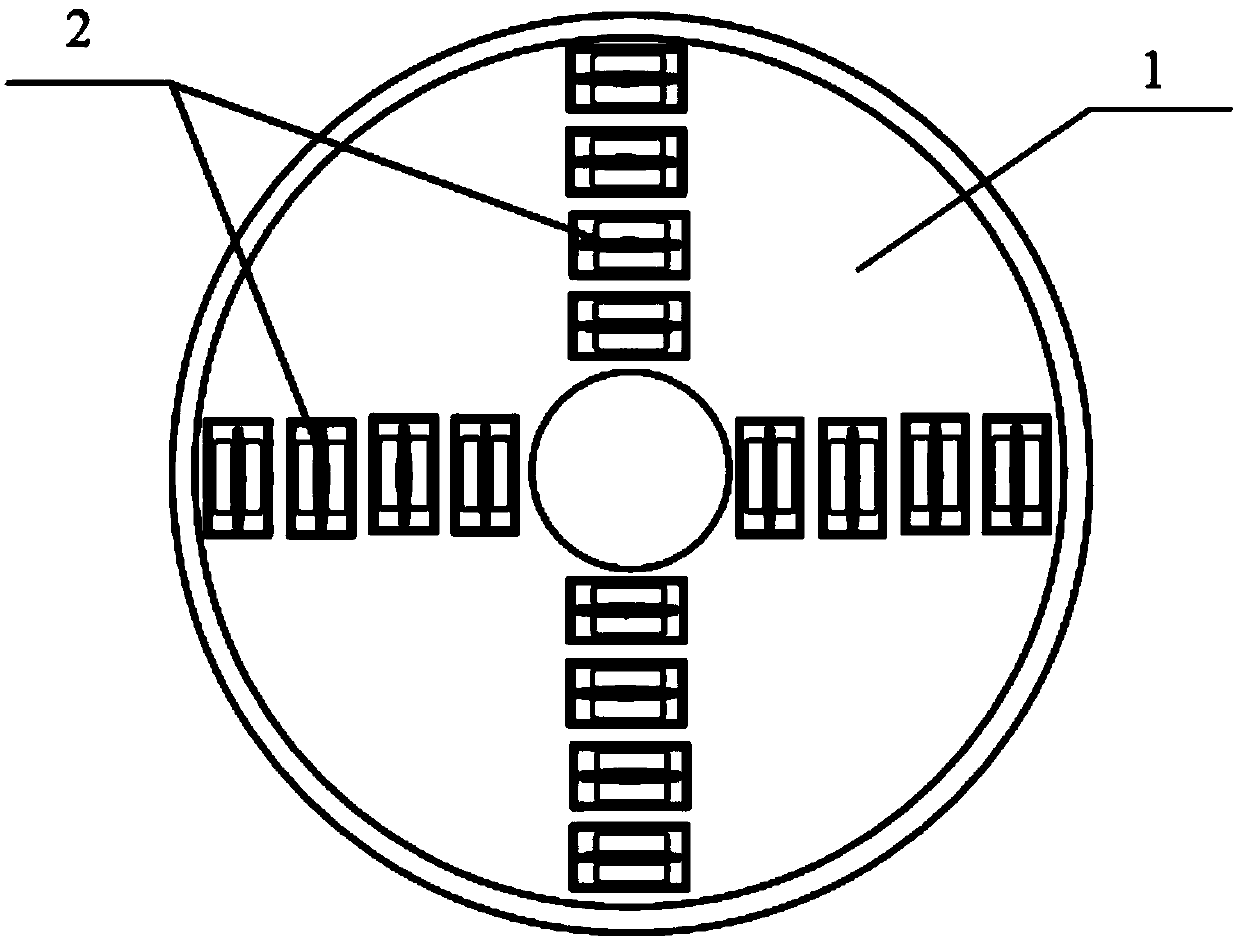

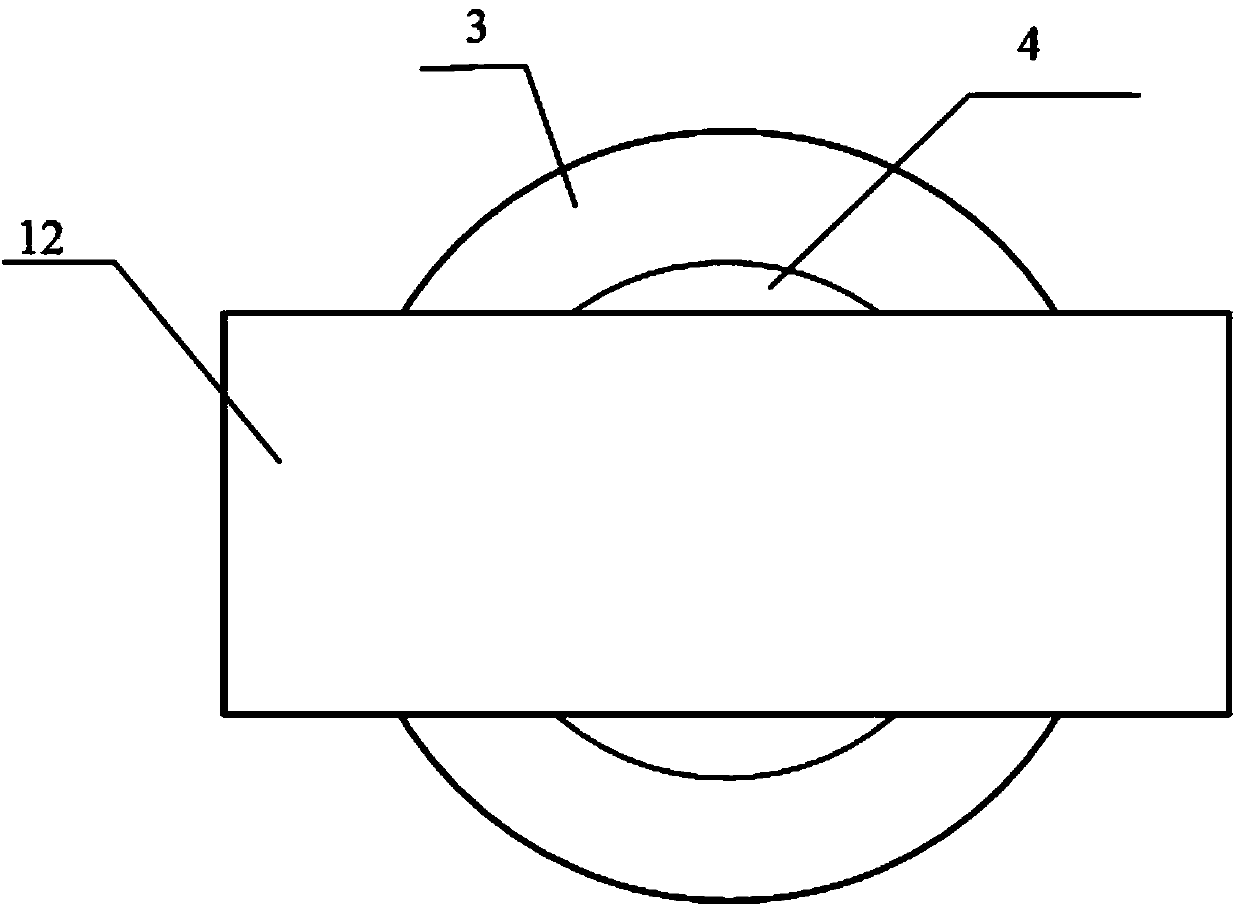

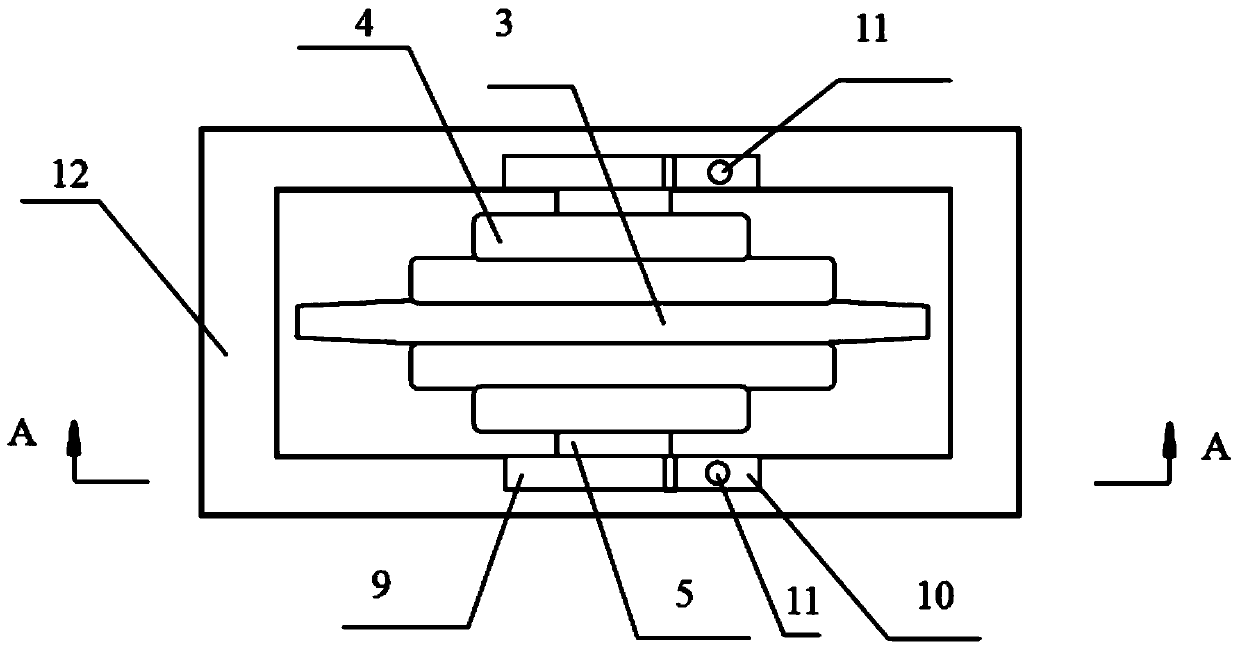

[0024] see Figure 1 to Figure 10 , a plurality of hob devices 2 are installed on the cutter head 1 of the full-section hard geological roadheader. The hob blade 3 is in the shape of a flat disc, also called a cutter ring. The hob blade 3 is supported on the tool central axis 5 through a bearing 4 Above, the two ends of the central axis 5 of the tool are respectively provided with a shaft end supporting structure.

[0025] The present invention is a device for on-line detection of hob stress of a full-section hard geological roadheader, comprising a shaft end support structure of the tool central axis 5, a sensor for detecting hob stress, a signal amplifier, a transmitting antenna, a signal receiving device and Monitor computer.

[0026] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com