Vertical shaft tunnel boring machine by shaft sinking method and construction method of tunnel boring machine

A technology for roadheaders and shafts, which is applied in shaft equipment, sinking, and earthwork drilling and mining, and can solve problems such as high risk, low degree of mechanization, and low efficiency, and achieve fast construction speed, convenient operation, and wide adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

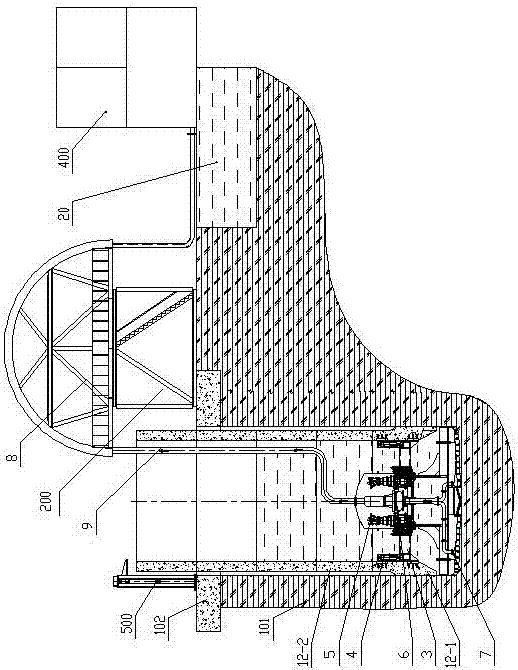

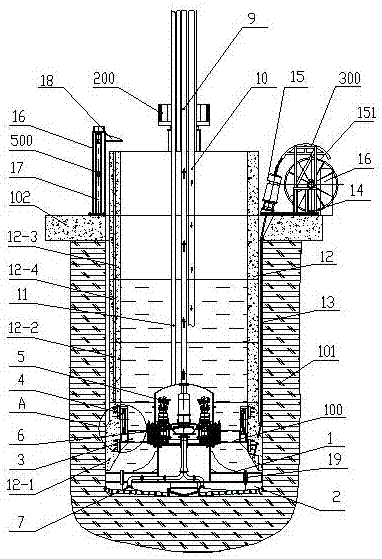

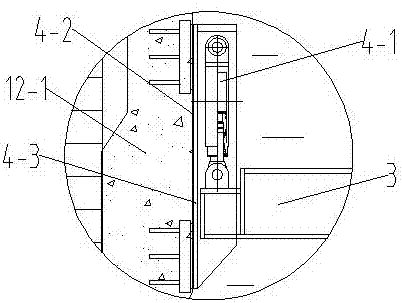

[0026] Embodiment 1: as Figure 1-3 As shown, a caisson shaft boring machine includes a drive system, a control system, and a detection system. The drive system provides the total power for the entire device, the control system controls the execution of the entire device's actions, and the detection system monitors the working status of the entire device at any time. ; Also includes interconnected tunneling mechanism 100, pipe arrangement 200, wellbore lifting mechanism 300 and slurry separation system 400 and auxiliary pressurization mechanism 500, pipe arrangement 200, wellbore lifting mechanism 300 and slurry separation system 400 and The auxiliary pressurization mechanism 500 is located on the wellhead ring beam 102 on the ground 101. The auxiliary pressurization mechanism 500 can apply downward pressure on the standard pipe joint to make it sink smoothly. The wellbore lifting mechanism controls the sinking speed of the wellbore ; A pipe-discharging mechanism 200 is arrang...

Embodiment 2

[0037] Example 2, such as Figure 1-3 As shown, a caisson method shaft boring machine, the shaft lifting mechanism 300 includes a lifting bracket 14, a lifting jack 15 and a lifting pump station 16, the lifting jack 15 is connected with the lifting pump station 16, and the lifting bracket 14 is provided with a On the reel 151 wound with the steel strand 13, the steel strand 13 passes through the lifting jack 15 and is connected with the bottom pipe joint 12-1 at the bottom of the well shaft 12, which can intermittently and continuously lift larger heavy objects until the design required Height, the system can realize synchronous lifting of multiple units. This device has the characteristics of stable lifting, safety, adjustable speed, reasonable structure design, flexible hoisting, and convenient maintenance.

[0038] Further, the auxiliary pressurization mechanism 500 includes a pressurization support 16, a pressurization cylinder 17 is provided at the bottom of the pressuriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com