Hard rock composite TBM (Tunnel Boring Machine) suitable for composite stratum and tunneling mode thereof

A composite stratum and composite technology, applied in underground chambers, shaft linings, tunnel linings, etc., can solve problems that cannot meet the construction requirements of complex strata, and achieve the effect of expanding the scope of geological adaptation, economical and practical, and extensive geological adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

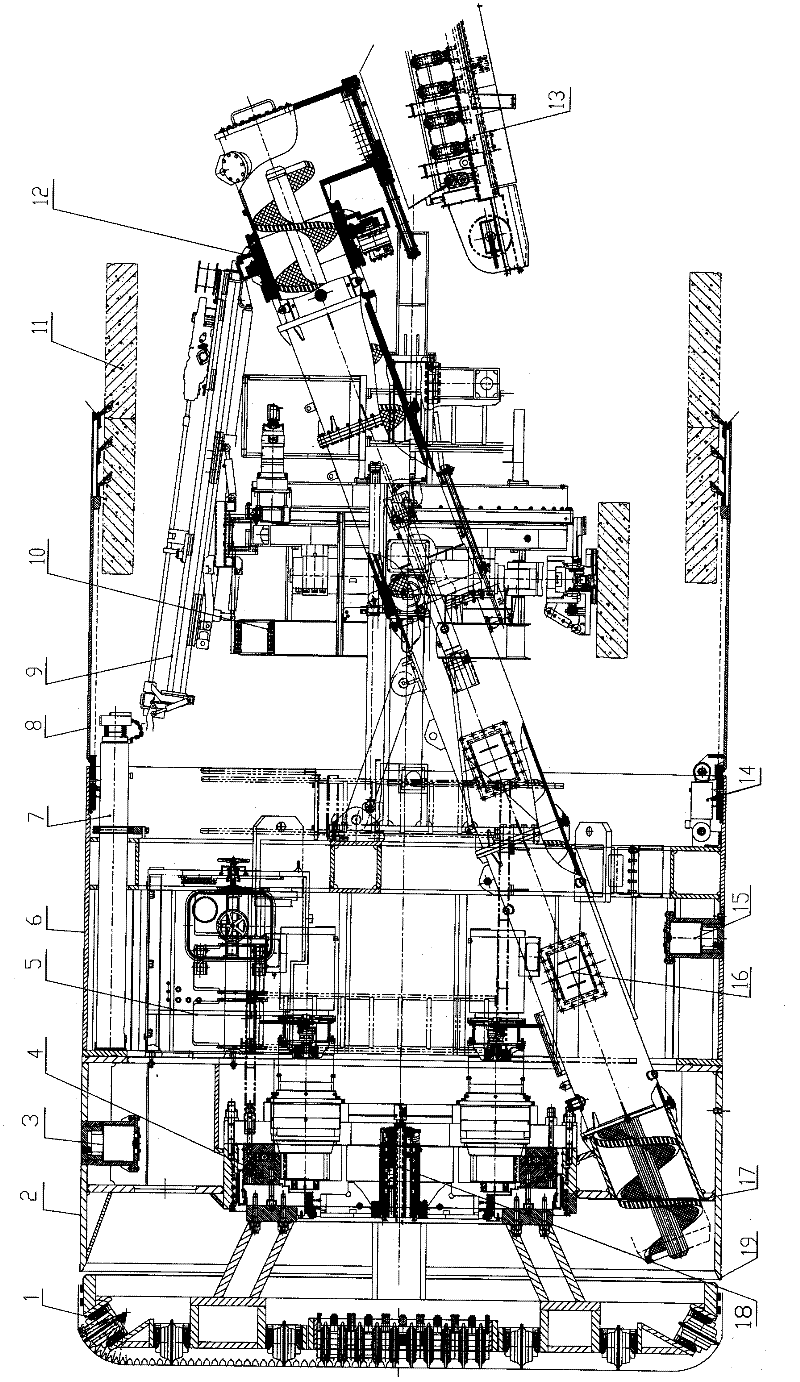

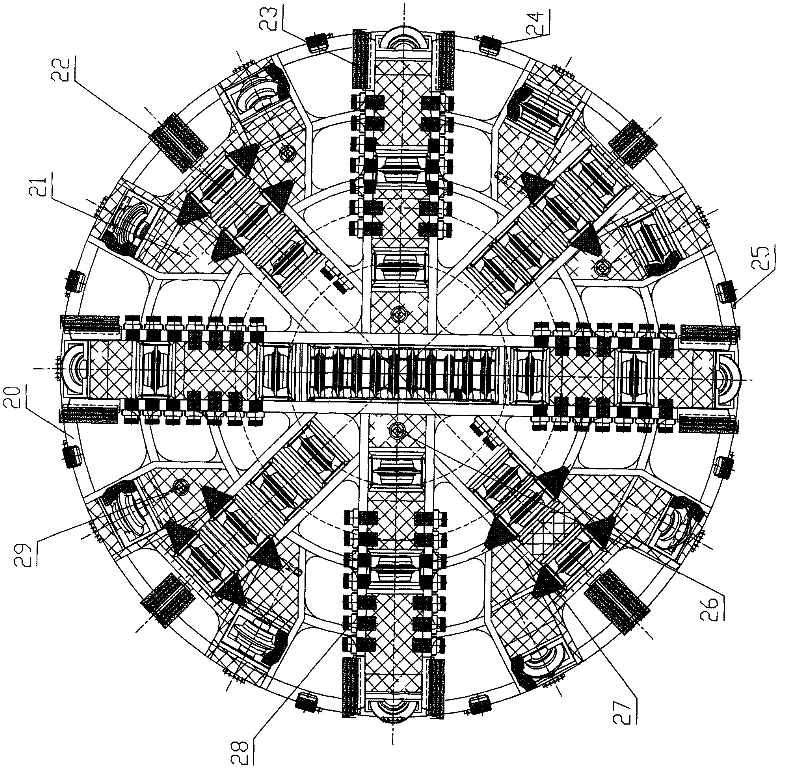

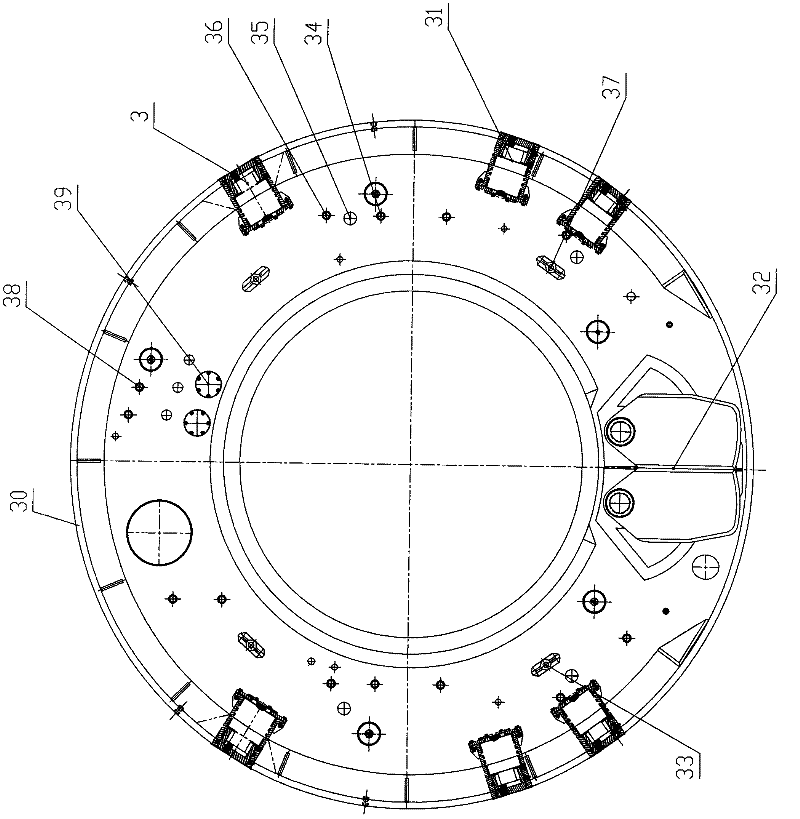

[0022] Below in conjunction with accompanying drawing, the present invention will be further described:

[0023] Such as figure 1 , figure 2 As shown, a hard rock composite TBM suitable for complex formations includes a cutter head 1 located at the front of the shield body, a front shield 2 connected to the cutter head 1, and a middle shield 6 connected to the front shield 2, and a middle shield 6 connected to the middle shield. The tail shield 8 connected to the shield 6 is characterized in that: the cutterhead 1 is a composite cutterhead, including a cutterhead steel structure 20, on which a wear-resistant panel 21 and a gauge knife 24 and The wear-resistant block 25 on the periphery of the cutter head located next to the gauge knife 24, the wear-resistant panel 21 is provided with a hob 22, a side scraper 23 and a scraper 28, and a hob protection block 27 is arranged around the hob 22 to meet the two-way Side scraper 23 and scraper 28 for rotary excavation; front shield ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com