Method and apparatus for determining center of casting impeller

An impeller and theoretical center technology, applied in the field of machining and manufacturing parts in the mechanical field, can solve problems such as product scrap, impeller dynamic balance cannot meet requirements, and it is difficult to accurately determine the actual center of the impeller, etc., to improve accuracy and improve yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

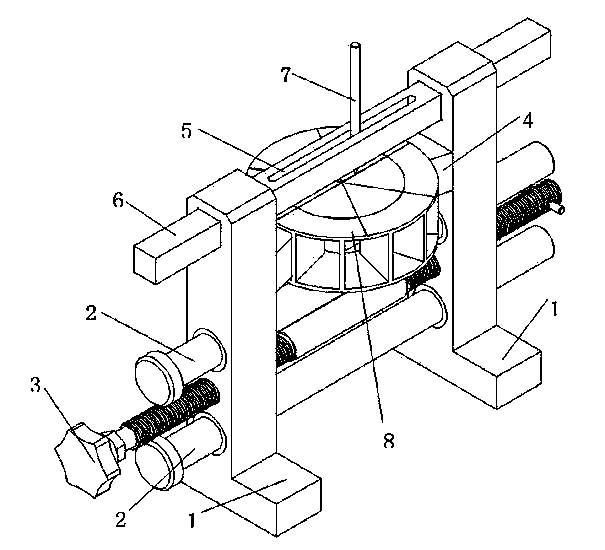

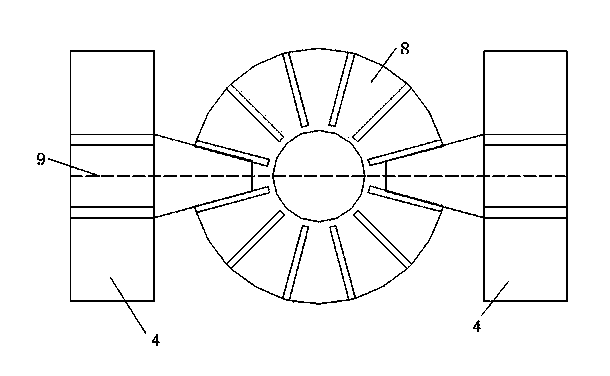

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] A method for determining the center of a casting impeller, select a movable wedge with the same shape and angle as the blade of the impeller; the movable wedge is installed on an adjustable and movable support frame; manually adjust the adjusting screw so that the position of the movable wedge is in line with the The impeller fits completely and the workpiece is clamped; the stylus slides left and right in the center reference groove to draw a theoretical center line on the workpiece; loosen the workpiece and turn the workpiece so that the workpiece rotates at an angle and fits closely with the movable wedge. Clamp the workpiece, draw another theoretical center line on the workpiece, and the two theoretical center lines intersect at one point; repeat the above steps of rotating the workpiece angle to draw the theoretical center line; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com