Tube shell type pulsating heat pipe heat exchanger

A pulsating heat pipe and heat exchanger technology, applied in the field of heat exchange devices, can solve the problems of large size and weight of heat pipes, complicated manufacturing process, failure and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

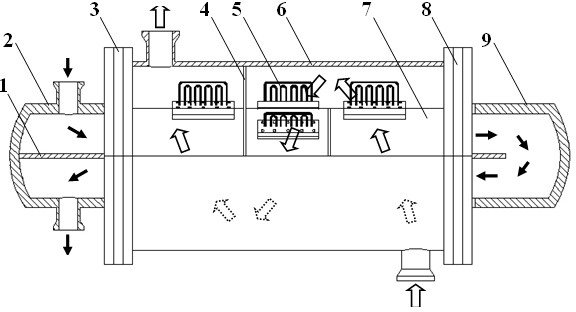

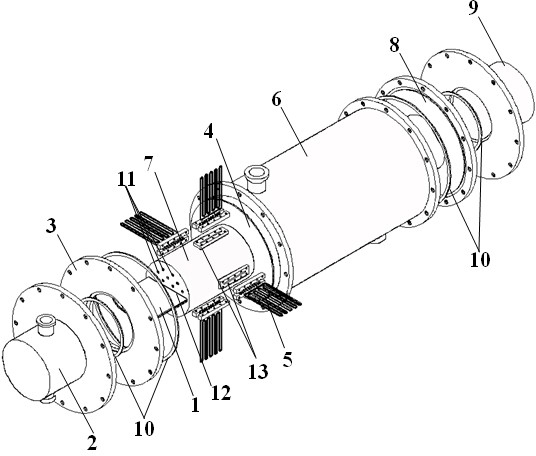

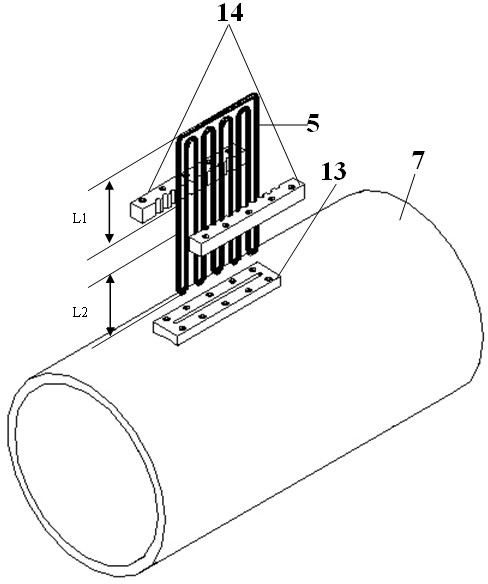

[0024] figure 1 and figure 2 A three-dimensional structure schematic diagram and an assembly schematic diagram of the present invention are provided respectively. It can be seen from the figure that the shell-and-tube pulsating heat pipe heat exchanger proposed by the present invention mainly includes a shell side 6, a tube side 7, sealing flanges 3, 8 and sealing heads 2, 9 arranged at both ends of the shell side. Such as figure 1 and figure 2 As shown, a partition 1 is used in the middle of the tube pass 7 to divide the tube pass 7 into two upper and lower return passages, and the partition plate 1 and the tube pass 7 are connected by expansion joints. 7 Honeycomb holes 11 through which fluid passes and through grooves 12 through which the partition plate 1 passes and is fixed are respectively processed on the wall surfaces at both ends separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com