Micro-channel pipeline heat exchanger

A micro-channel heat exchanger and micro-channel technology, applied in indirect heat exchangers, heat exchanger types, lighting and heating equipment, etc., can solve the problems of high cost, complex manufacturing process, easy cracking and leakage, etc. The effect of water flow convection heat transfer area, increasing convection heat transfer area, and enhancing flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further described in conjunction with the following examples.

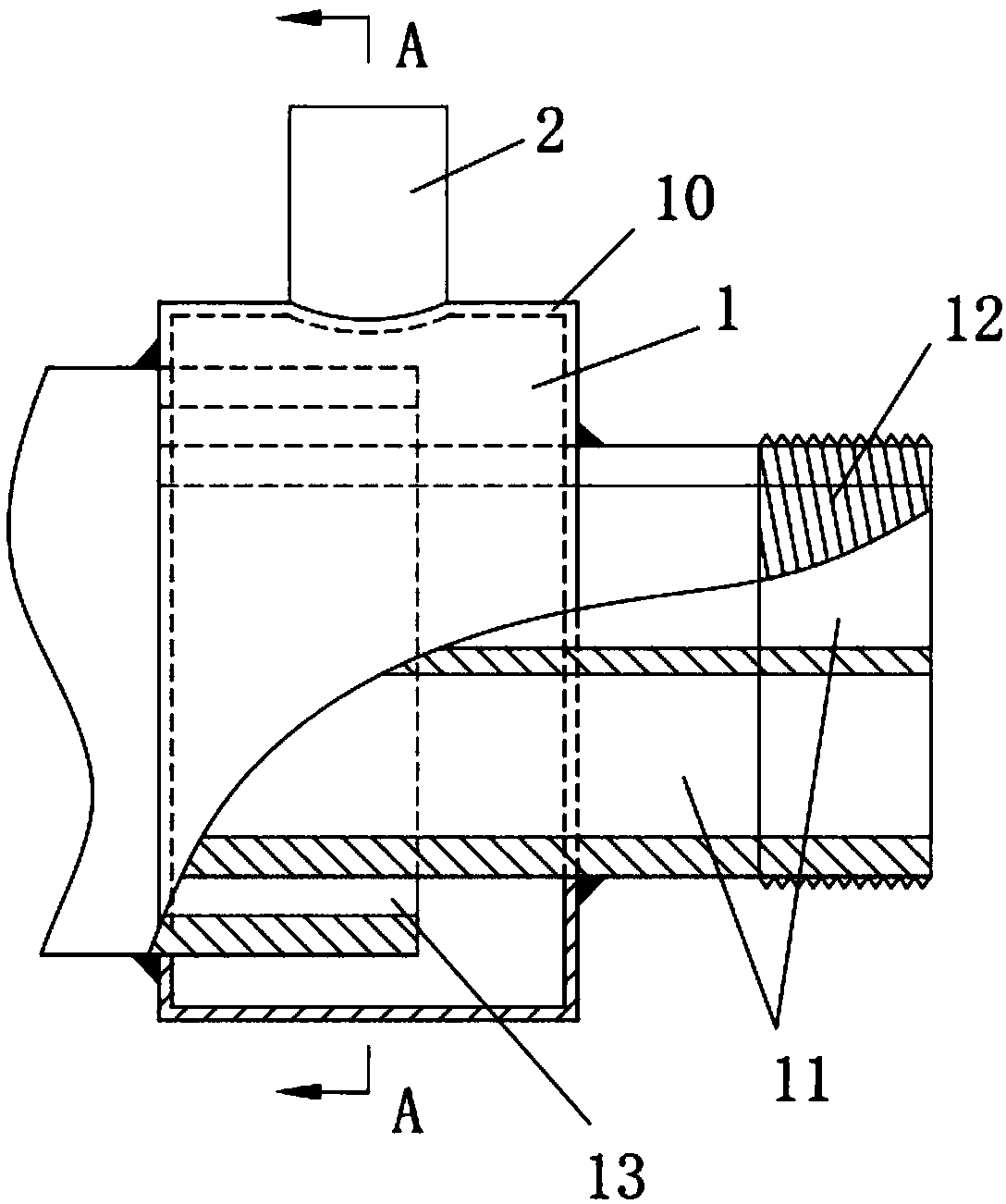

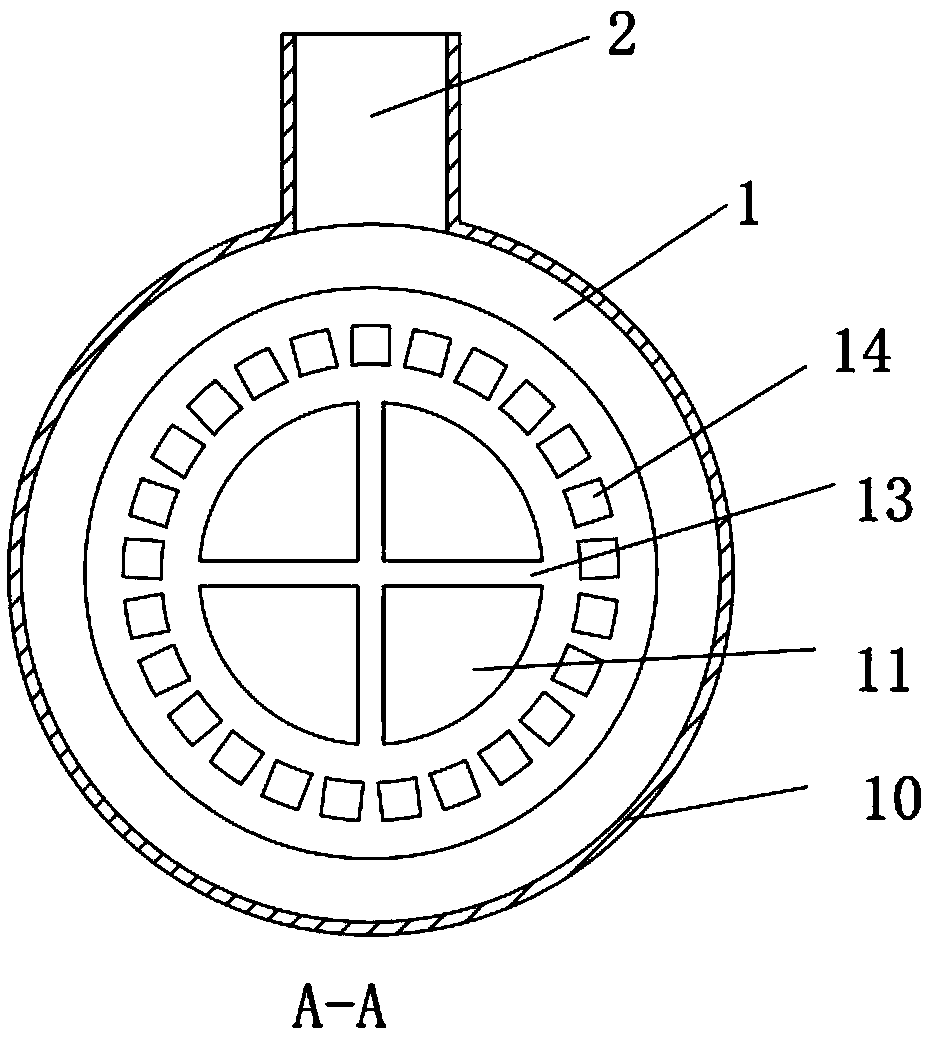

[0017] The specific embodiment of a kind of microchannel 14 pipeline heat exchangers of the present invention, as Figure 1-Figure 2 As shown, the microchannel 14 pipe heat exchanger includes a heat exchanger pipe 1 and an end joint 2 of the heat exchanger pipe 1, and the heat exchanger pipe 1 includes an outer wall 10 and an inner pipe 11, so The inner pipe 11 is a water flow channel, and the inner pipe 11 is extended with a water pipe connector 12. The outer surface of the water pipe connector 12 is provided with an external thread, and the external thread is a mechanically processed connecting thread. 12 is threadedly connected with the external circulating water pipe joint to prevent leakage. The water path flows into the inner pipe 11 through the external circulating water pipe joint. The inner pipe 11 is provided with a connecting rib 13 in the radial direction, and the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com