Device and method for utilizing cyclic cooling water in cooling tower of steel plant to generate power

A technology for circulating cooling water and power generation devices, which is applied to electromechanical devices, hydroelectric power generation, and devices for coating liquid on the surface. It can solve the problems of low interlayer shear strength, large power generation resistance, and high density. It is easy to implement, Energy saving and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

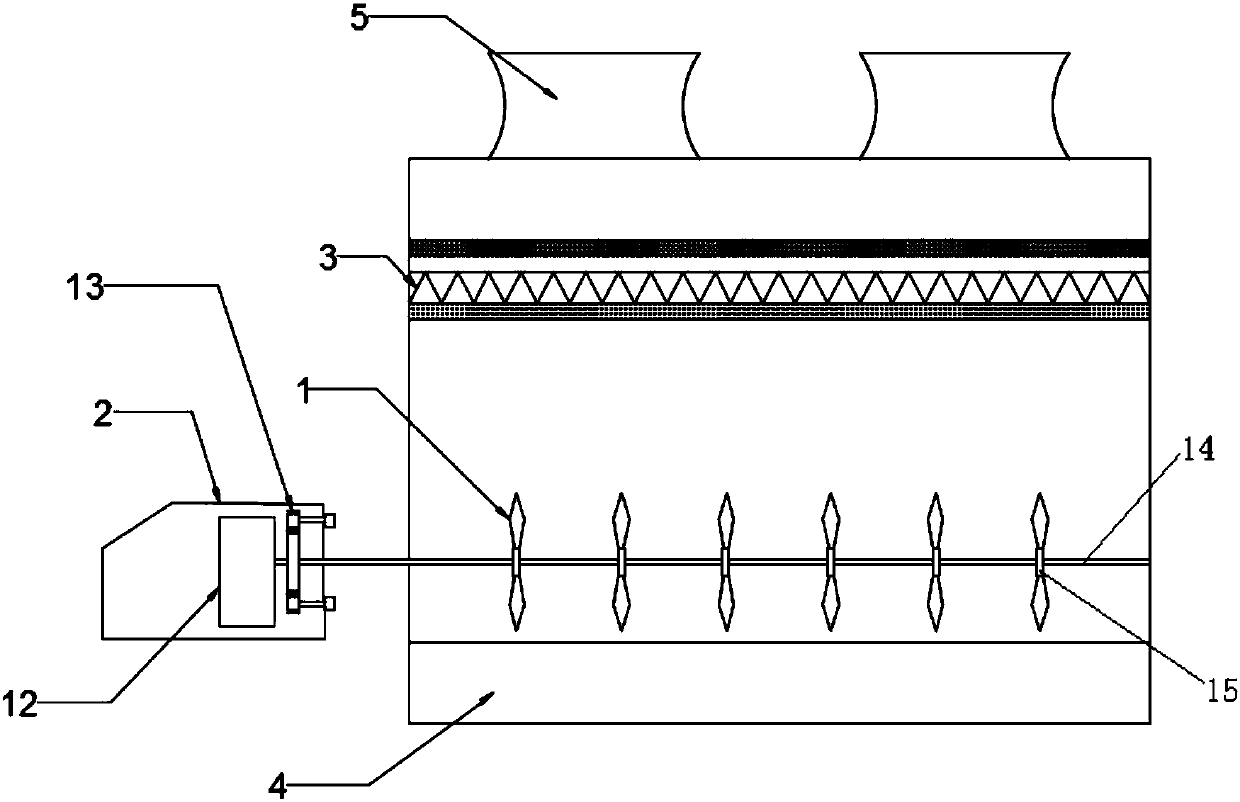

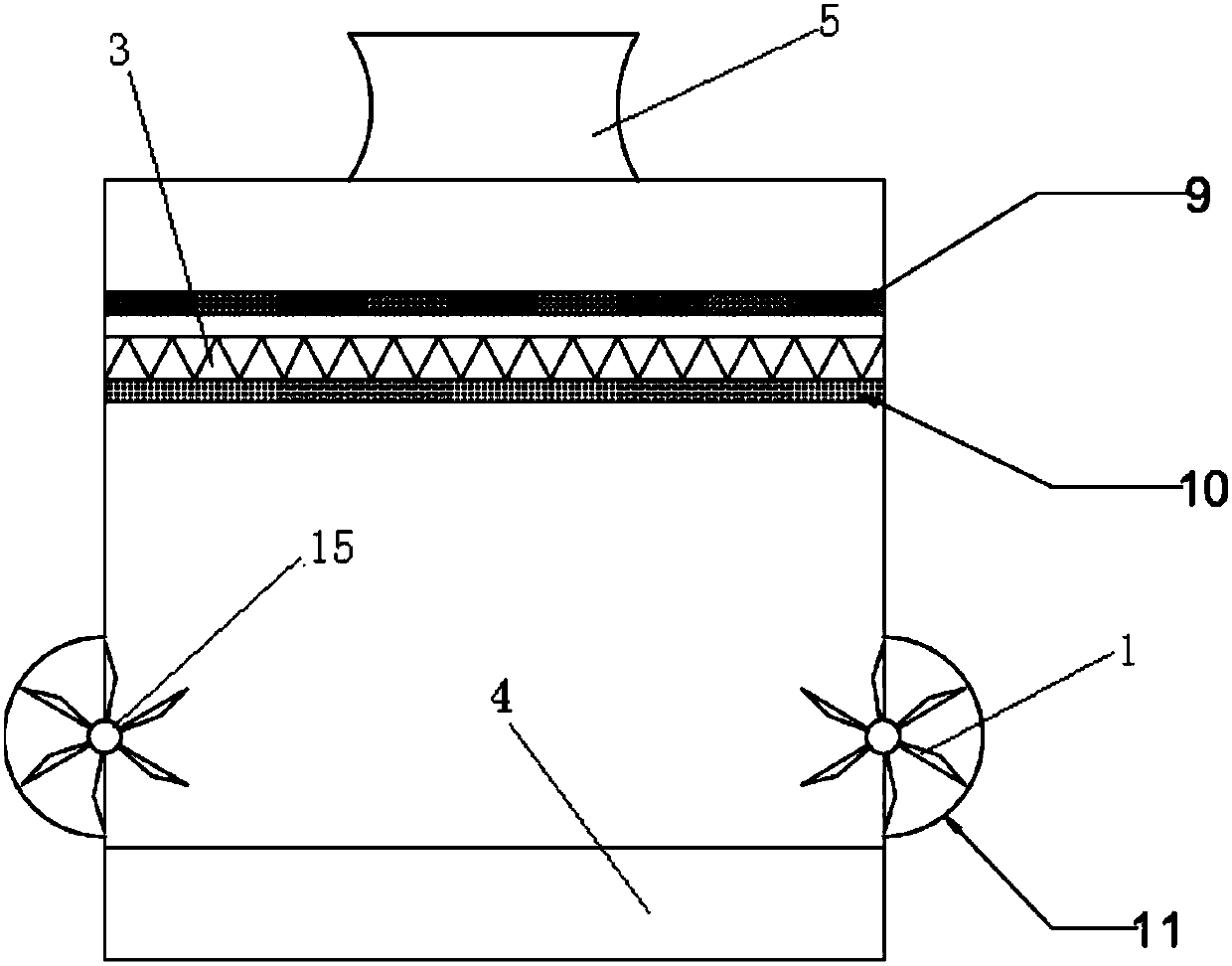

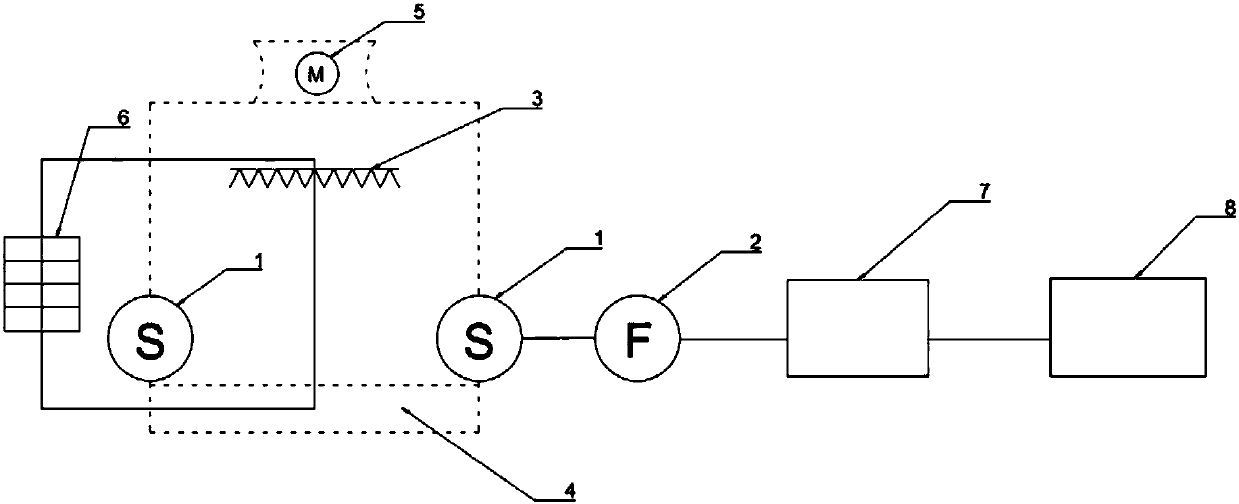

[0044] Taking a cooling tower in a steel factory as an example, the cooling water flux is 6000t / h, the height of the water distribution pipe is 8m, the cooling water temperature is 60°C-95°C, and the gravitational potential energy of the water passing within 1h is 4.8×10 5 kJ, the comprehensive utilization coefficient is 0.3 (the specific energy utilization coefficient varies with the cooling tower and cooling water composition), that is, 1.44×10 5 The energy of kJ is converted into mechanical energy, and this part of mechanical energy is used for power generation, and its power generation efficiency is 85%.

[0045] Therefore, it can generate 34kwh per hour.

[0046] In some embodiments, the power generation method improves the cooling efficiency, and the cooling process does not use a fan to draw air, and the required temperature drop can also be achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com