Micro convex array type thermoelectric generator heat exchange module

A technology of heat exchange modules and thermoelectric generators, which is applied in the direction of generators/motors, electrical components, etc., to achieve the effects of improving heat exchange efficiency, simple structure, and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and embodiments.

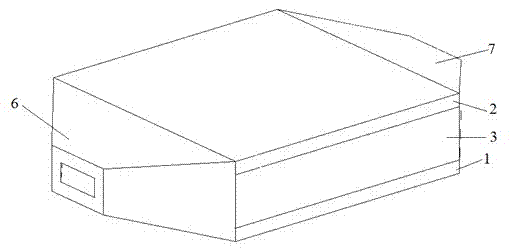

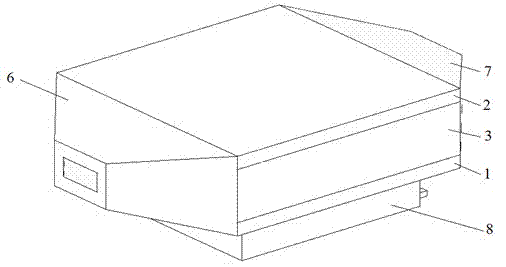

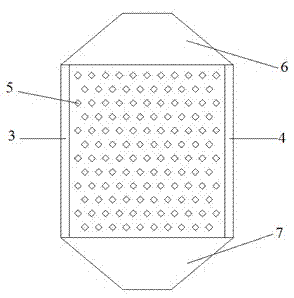

[0020] Such as Figure 1 ~ Figure 5 As shown, the present invention includes a heat exchange module bottom plate 1, an upper cover plate 2, a left side plate 3, a right side plate 4, a micro boss array 5, an inlet 6 and an outlet 7; the micro boss array 5 is installed on The upper end surface of the heat exchange module bottom plate 1, the upper end of the micro boss array 5 is in contact with the lower end surface of the upper cover plate 2, and the left side plate 3 and the right side plate 4 are respectively installed on the left and right sides of the thermoelectric generator heat exchange module bottom plate 1. On the side, the inlet 6 and outlet 7 are respectively installed at the front and back of the thermoelectric generator heat exchange module; the hot fluid enters the thermoelectric generator heat exchange module from the inlet 6 and flows through the micro-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com