Porous medium liquid-cooling cooling device, manufacturing method and use method thereof

A technology of porous media and manufacturing method, which is applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc. Small convection heat transfer thermal resistance, improved heat dissipation effect, and the effect of enhancing heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

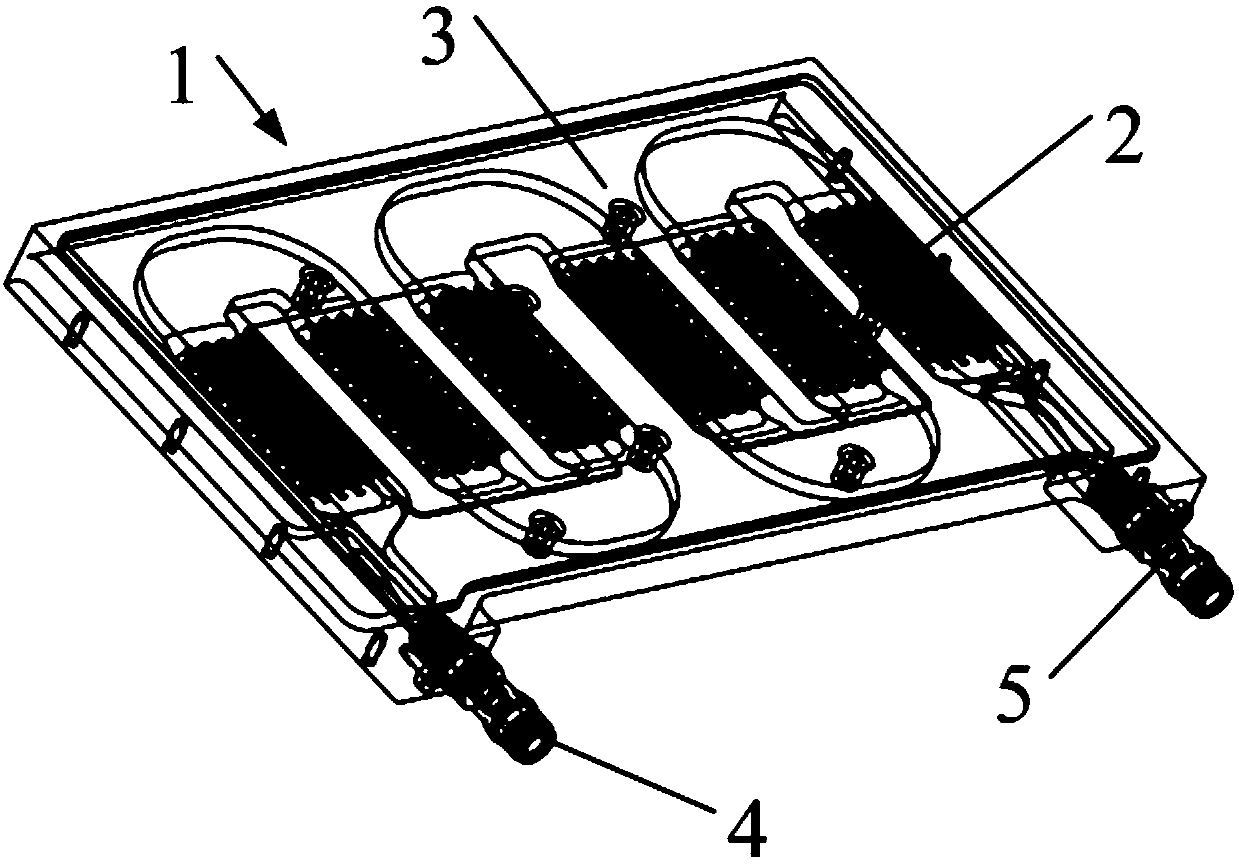

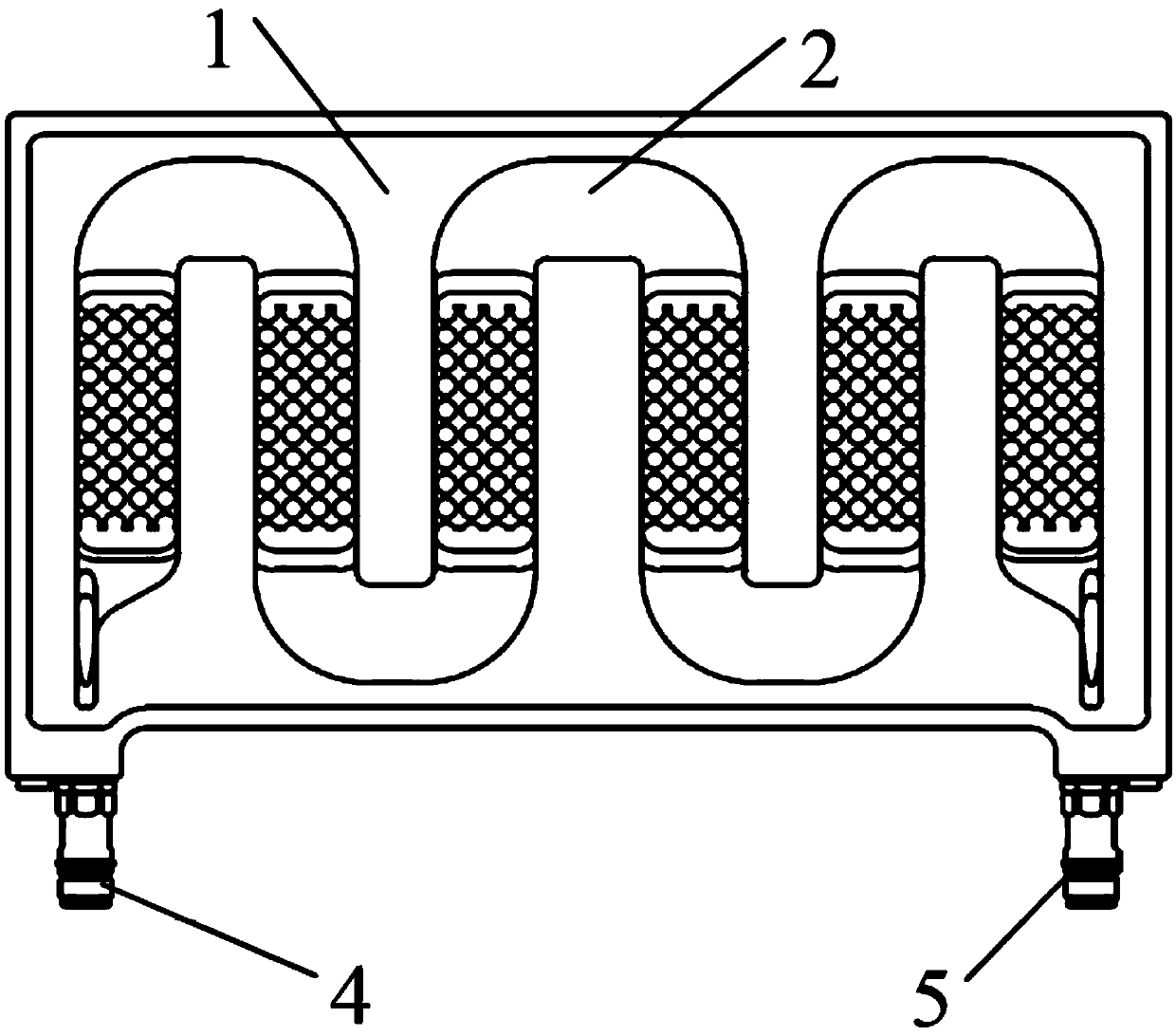

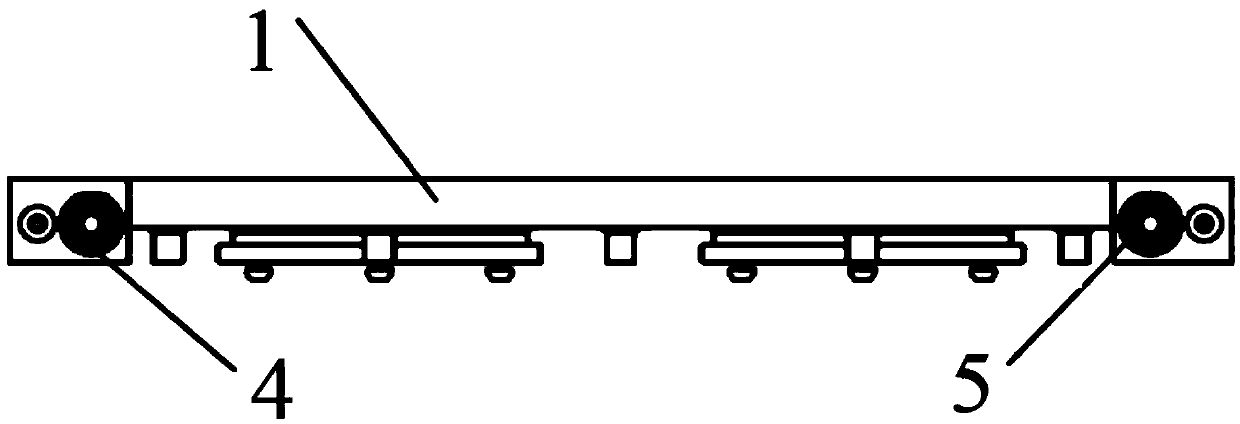

[0037] The invention provides a porous medium liquid cooling device, such as Figures 1 to 3 As shown, it includes: a base plate 1 , a porous medium module 2 and a cover plate 3 .

[0038] The substrate 1 is provided with a heat dissipation medium diversion groove, one end of the heat dissipation medium diversion groove is provided with a heat dissipation medium inlet joint 4, and the other end of the heat dissipation medium diversion groove is provided with a heat dissipation medium outlet joint 5; the porous medium module 2 It is filled into the heat dissipation medium diversion groove, so that the heat dissipation medium flows inside the heat dissipation medium diversion groove, causing disturbance; the cover plate 3 is covered on the base plate 1, and is sealed and connected with the base plate 1, so that the heat dissipation medium diversion groove forms a heat dissipation The medium guide chamber, the heat dissipation medium flows inside the heat dissipation medium guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com