Fuel cell flow field plate and fuel cell

A fuel cell and flow field plate technology, which is applied to fuel cells, fuel cell components, circuits, etc., can solve the problems of uneven gas distribution, low electrode surface utilization rate, low reaction gas flow rate, etc., and achieves increased convective conversion Thermal area, reduced assembly workload, and uniform temperature field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

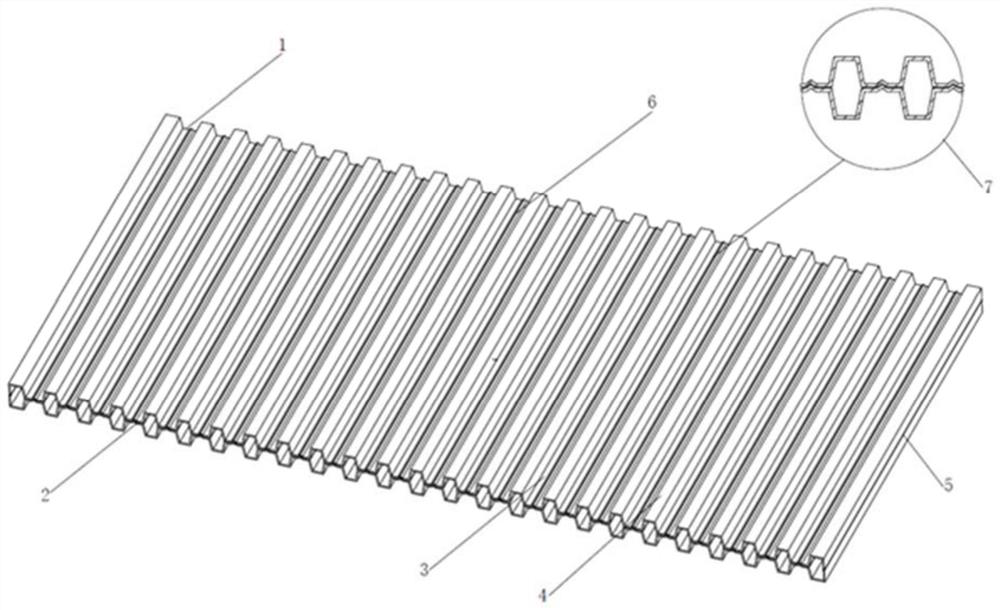

[0033] like figure 1 As shown, a fuel cell flow field plate provided by the present invention is mainly suitable for hydrogen-air fuel cells and hydrogen-oxygen fuel cells, the flow field plate is made of metal material, the cathode plate includes an air inlet, Gas outlet, flow channel, ridge, groove at the bottom of the flow channel groove, the anode plate includes air inlet, gas outlet, flow channel, ridge, and boss at the bottom of the flow channel groove. The air inlet and the air outlet are connected through flow channels on the flow field plate. The flow channel adopts parallel flow channel, the cross section of the flow channel adopts trapezoidal cross section, and the groove and boss at the bottom of the flow channel are triangular. When the battery is assembled, the groove of the cathode plate and the boss of the anode plate cooperate with each other to fix the two plates so that they cannot move. When the flow field plate of the present invention is in operation, t...

Embodiment 2

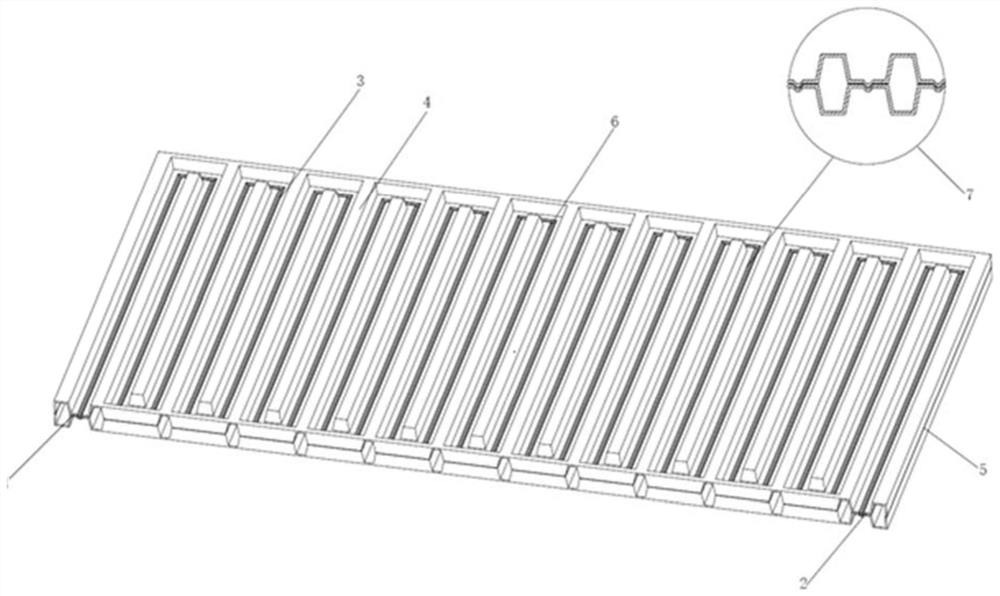

[0035] like figure 2 As shown, a fuel cell flow field plate provided by the present invention is mainly suitable for hydrogen-air fuel cells and hydrogen-oxygen fuel cells, the flow field plate is made of metal material, the cathode plate includes an air inlet, Gas outlet, flow channel, ridge, groove at the bottom of the flow channel groove, the anode plate includes air inlet, gas outlet, flow channel, ridge, and boss at the bottom of the flow channel groove. The air inlet and the air outlet are connected through flow channels on the flow field plate. The flow channel adopts a serpentine flow channel, the cross section of the flow channel adopts a trapezoidal cross section, and the groove and the boss at the bottom of the flow channel are arc-shaped. When the battery is assembled, the groove of the cathode plate and the boss of the anode plate cooperate with each other to fix the two plates so that they cannot move. When the flow field plate of the present invention is in o...

Embodiment 3

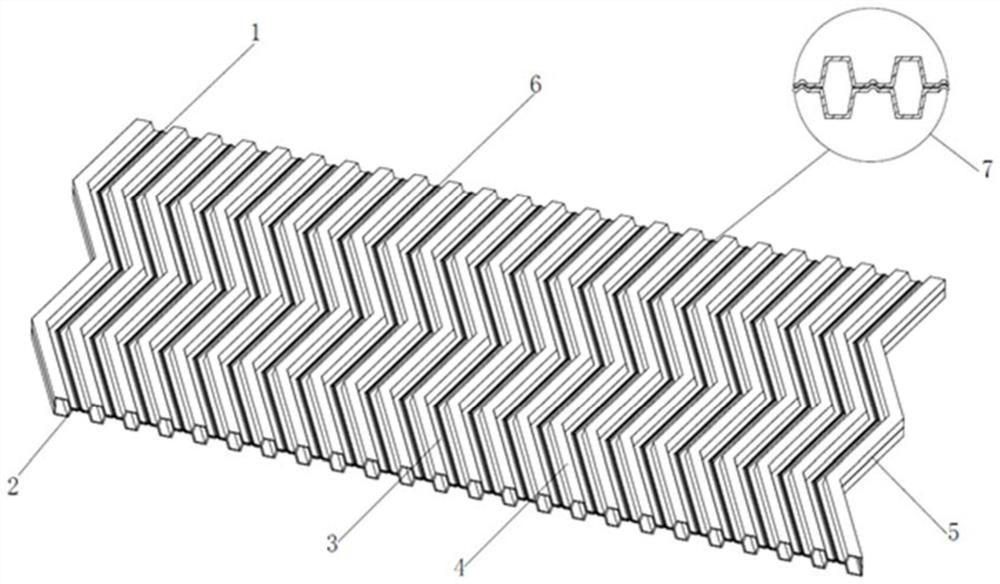

[0037] like image 3 As shown, a fuel cell flow field plate provided by the present invention is mainly suitable for hydrogen-air fuel cells and hydrogen-oxygen fuel cells, the flow field plate is made of metal material, the cathode plate includes an air inlet, Gas outlet, flow channel, ridge, groove at the bottom of the flow channel groove, the anode plate includes air inlet, gas outlet, flow channel, ridge, and boss at the bottom of the flow channel groove. The air inlet and the air outlet are connected through flow channels on the flow field plate. The flow channel adopts a folded flow channel, the cross section of the flow channel adopts a trapezoidal cross section, and the groove and the boss at the bottom of the flow channel are trapezoidal. When the battery is assembled, the groove of the cathode plate and the boss of the anode plate cooperate with each other to fix the two plates so that they cannot move. When the flow field plate of the present invention is in opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com