Device for using flue gas waste heat of rotary cement kiln to preheat air

A cement rotary kiln and flue gas waste heat technology, applied in the field of preheating air devices, can solve the problems of unsuitable combustion air preheating, large blower power increase, and affecting combustion efficiency, so as to facilitate temperature rise and suppress ash Resistance, the effect of improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

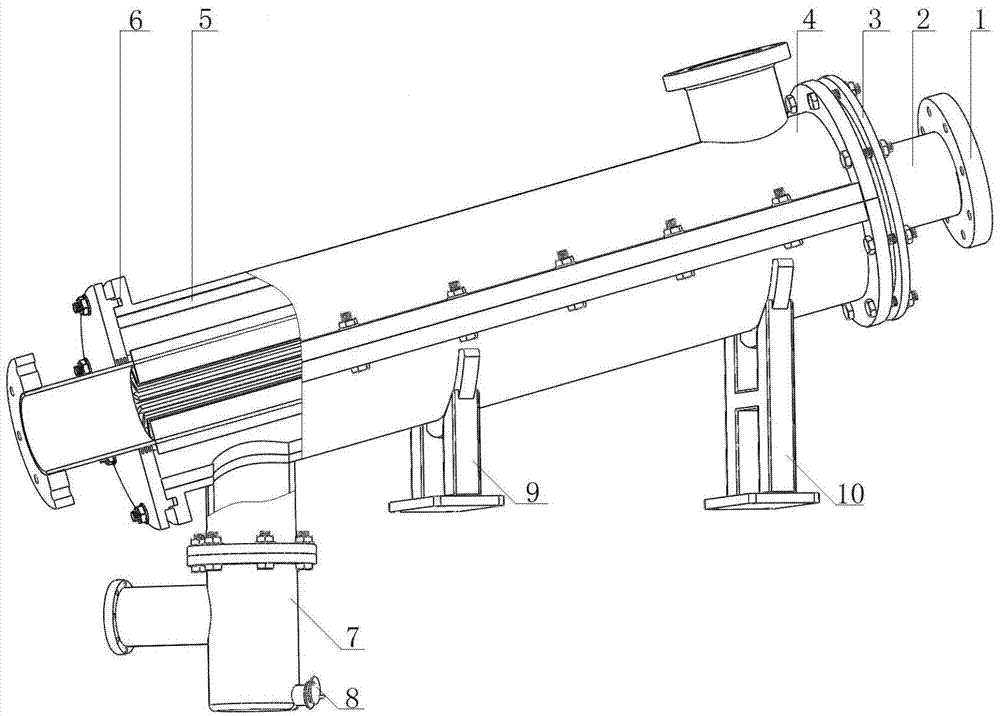

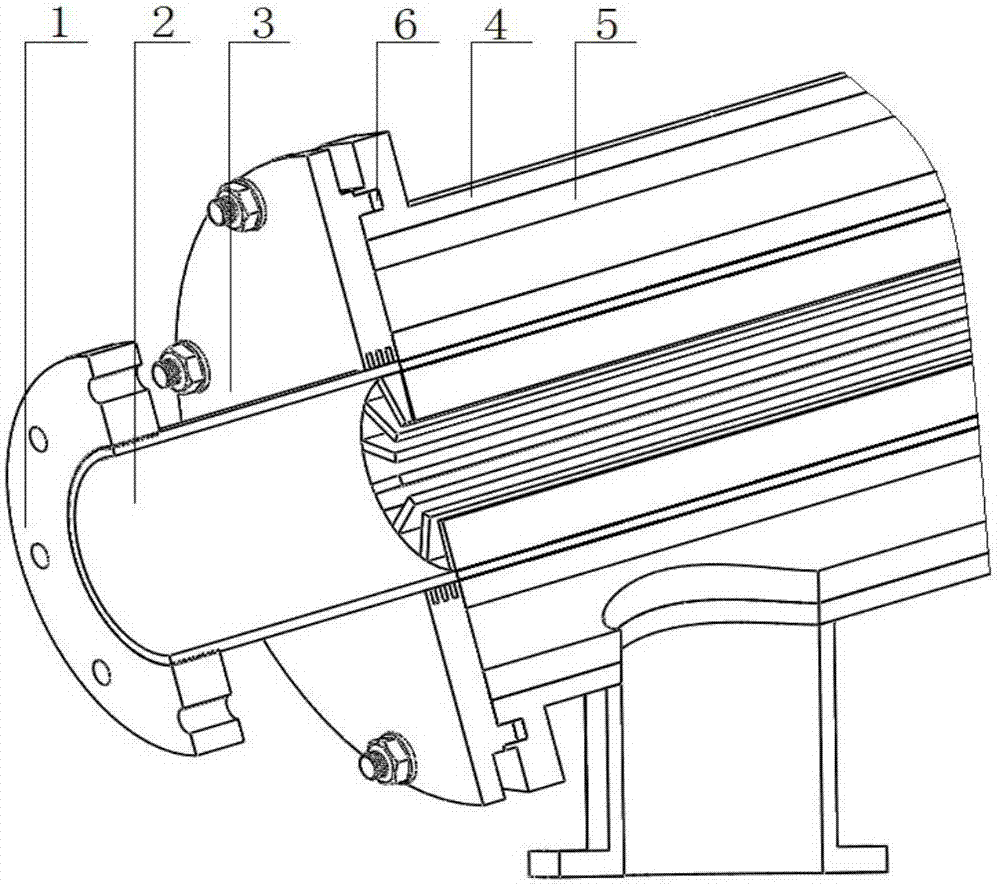

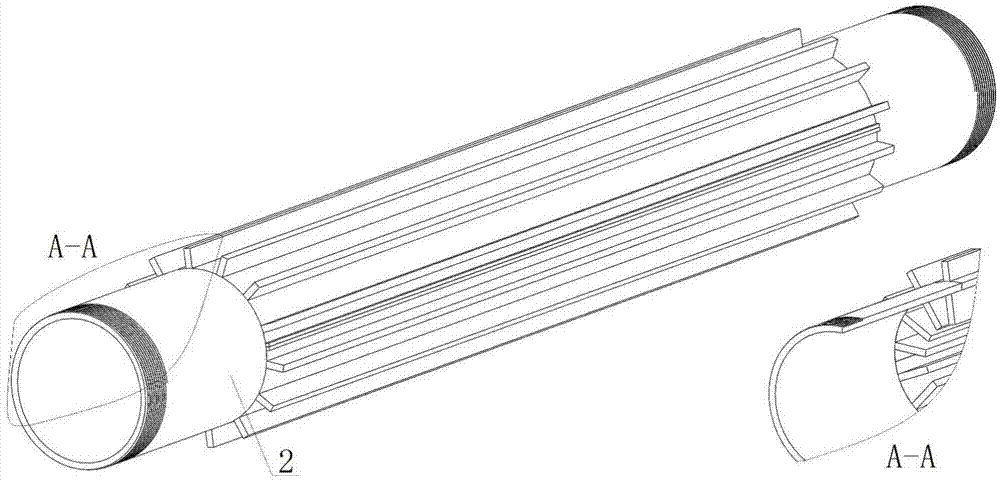

[0019] Such as Figure 1~5 As shown, a device for preheating air by using the waste heat of flue gas from a cement rotary kiln, the device includes: threaded flange 1, ribbed pipe 2, flange 3, shell 4, refractory lining 5, sealing ring 6, gravity dust removal Joint 7, dust removal end cover 8, low support 9 and high support 10, the shell 4 is formed by two semicircular steel shells connected by bolts, and its inner surface is provided with a refractory lining 5, the refractory lining material is Waxstone brick; the ribbed tube 2 is inside the shell 4, and the ribbed tube 2 is welded by two semicircular ring-shaped steel structures and two sections of threaded plain tubes, the two ends of the ribbed tube are bare tubes, and the The pipe passes through the flange with holes and is screwed with the threaded flange. The inner and outer surfaces of the ribbed pipe 2 are welded with 14 straight fins along the axial direction. The air flows inside the ribbed pipe 2. The outer surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com