Method for calculating quenching medium heat exchange coefficient by combining finite element method with inverse heat conduction method

A quenching medium and heat transfer coefficient technology, which is applied in the fields of calculation, electrical digital data processing, special data processing applications, etc., can solve the problems of inability to accurately control the quenching cooling rate of industrial parts, the error of heat transfer coefficient, and the difficulty in measuring the cooling rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

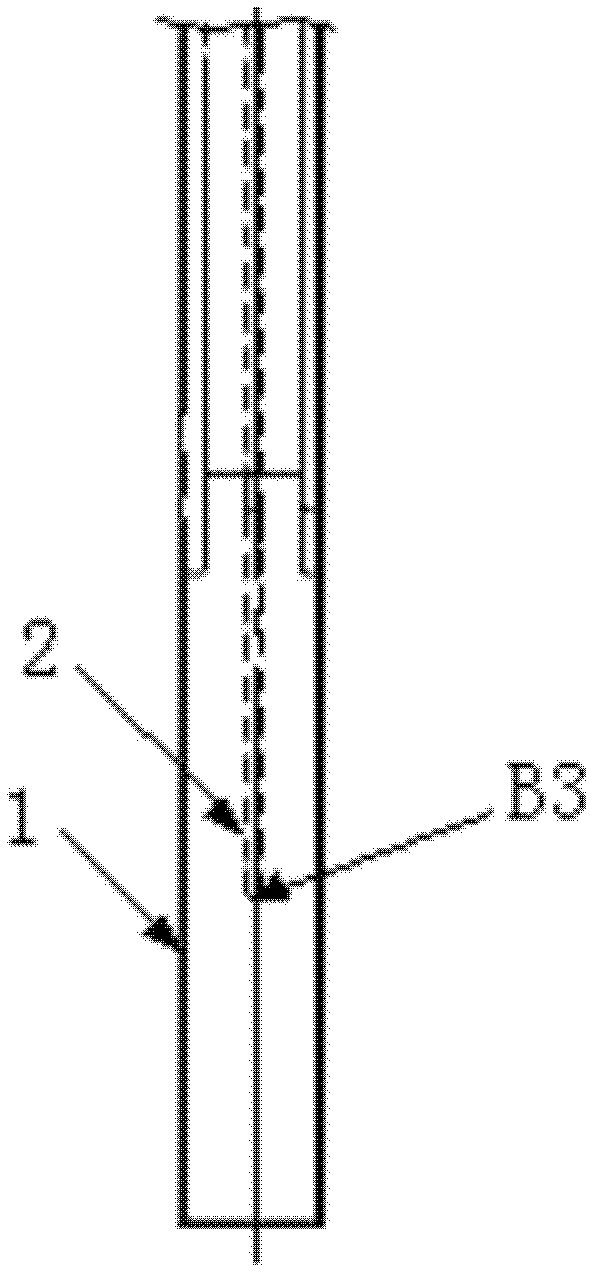

[0041] Specific implementation mode one: combine Figure 1 to Figure 7 Describe this embodiment, the method for calculating the heat transfer coefficient of the quenching medium in combination with the finite element method and the reverse heat transfer method of this embodiment, the specific process of the method for calculating the heat transfer coefficient of the quenching medium is:

[0042] Step 1. Heat the probe body 1 with the thermocouple 2 inserted inside it in the heating furnace to 860°C and keep it evenly, and then quickly quench it into the quenching medium with a transfer time of no more than 2s. The temperature of the quenching medium is set to T w , using a computer system to record the temperature of the internal feature point B3 of the probe body 1 measured by the thermocouple 2, and draw a cooling curve, that is, to obtain the cooling curve of the quenching medium at this temperature;

[0043] Step 2. Based on the ABAQUS finite element platform, use the fini...

specific Embodiment approach 2

[0070] Embodiment 2: The quenching medium in the step 1 of this embodiment is water, No. 20 engine oil or UCON-A (water-soluble polymer) quenching agent.

specific Embodiment approach 3

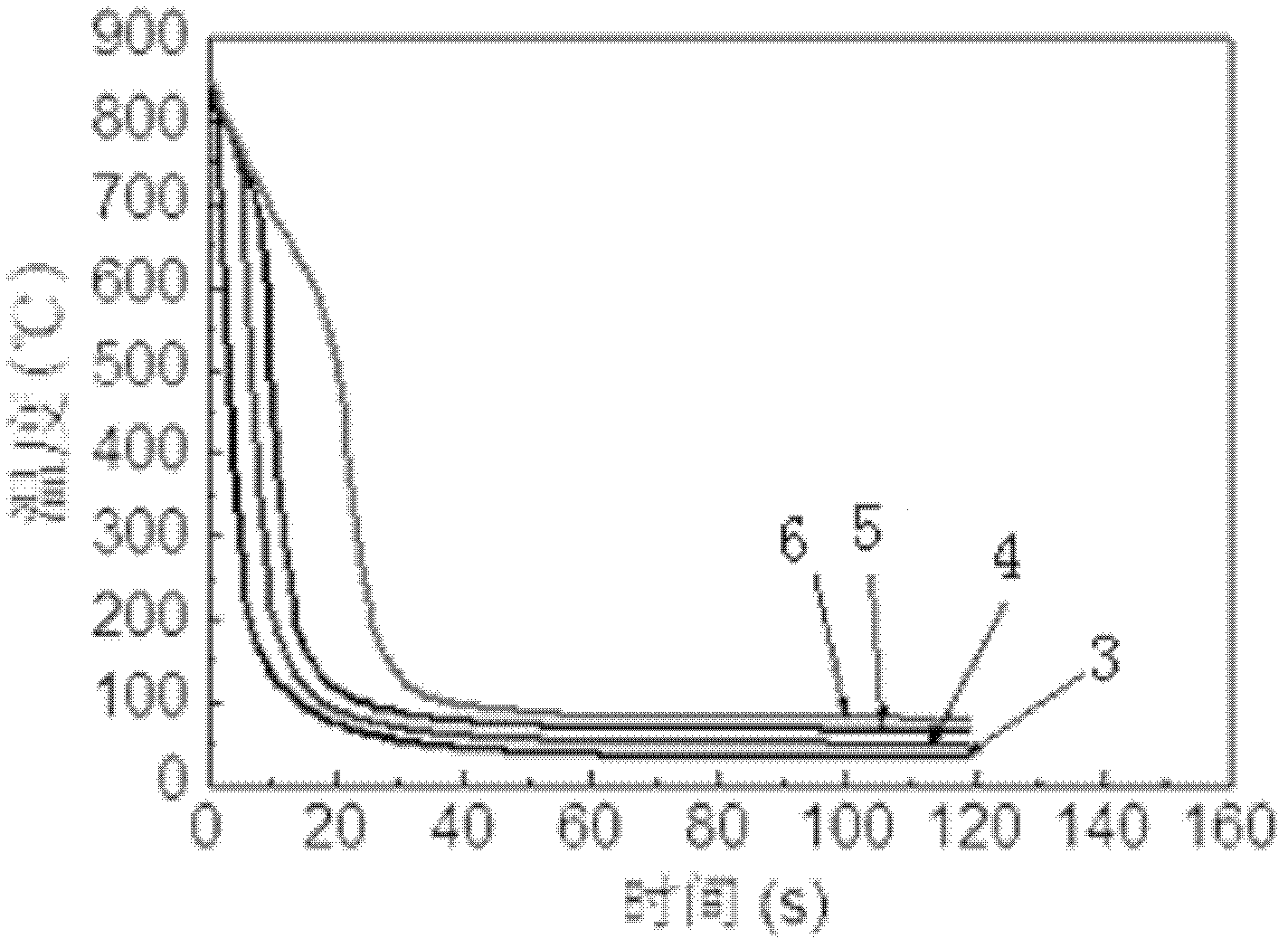

[0071] Embodiment 3: When the quenching medium in step 1 of this embodiment is water, the temperature of the quenching medium is set to 25°C, 45°C, 60°C or 80°C. Determine the temperature of the quenching medium according to the physical properties of the quenching medium and the actual operating temperature. For the cooling curve, see figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com