Volume heat exchange heat absorber for solar heat generation system

A technology for solar thermal power generation and heat sinks, applied in the field of heat sinks, can solve the problems that the heat sinks are not well resolved, the glass plate is softened, melted, and the thermal stress of the heat sink is high, so as to avoid local ablation and improve the The effect of heat diffusing ability and enhancing heat transfer ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

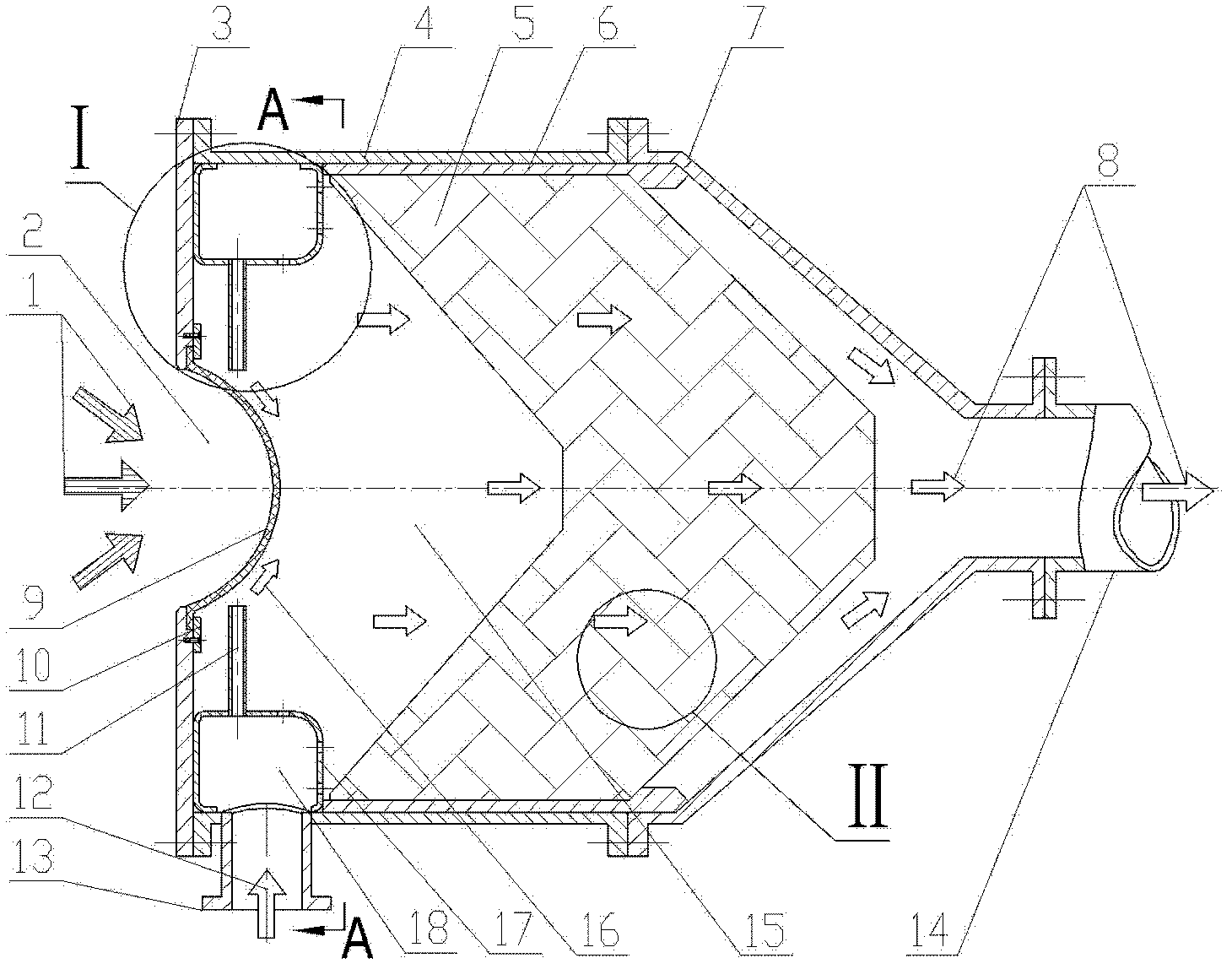

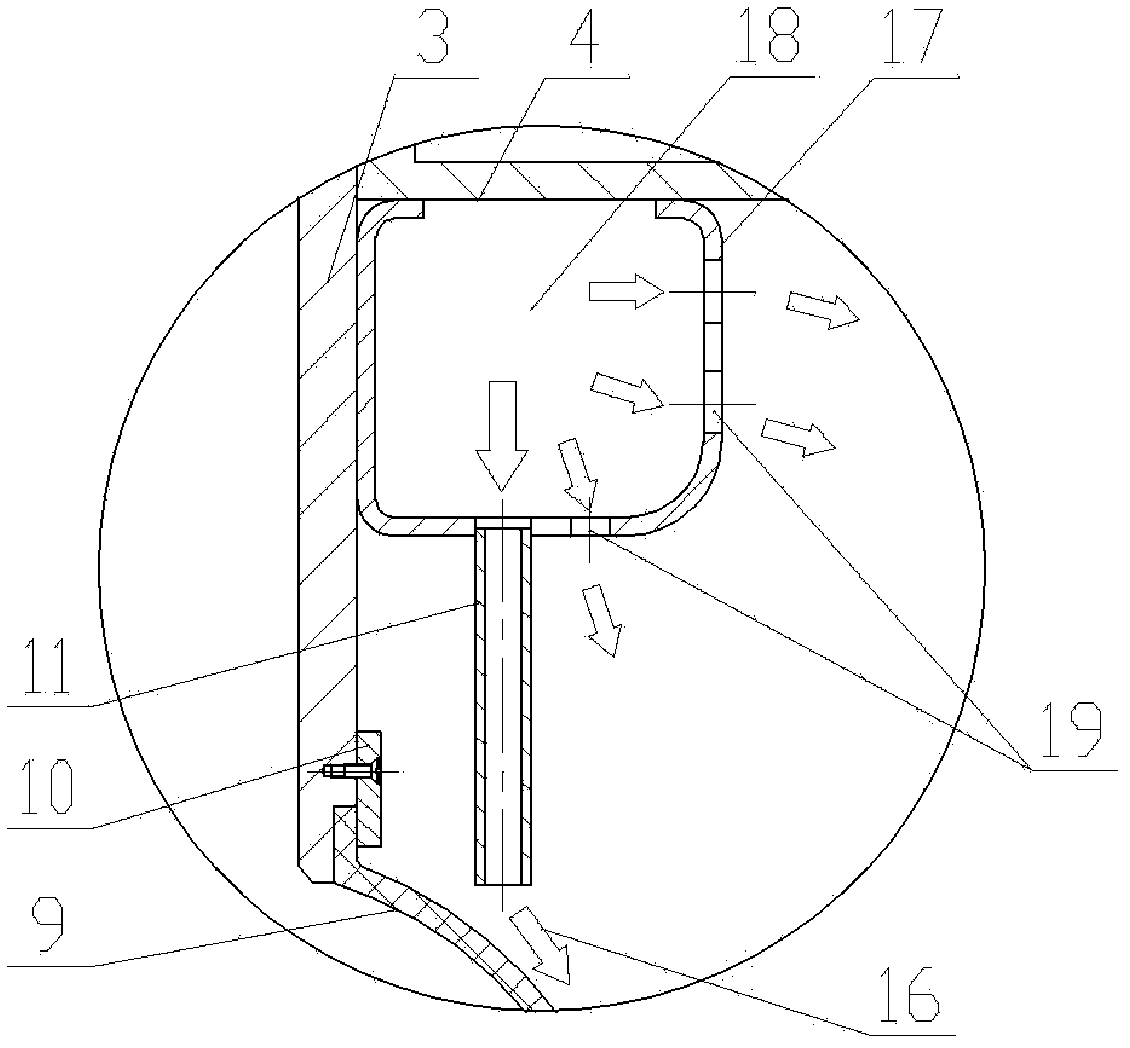

[0047] A volumetric heat exchanger absorber for solar thermal power generation systems, such as figure 1 As shown, it includes the shell of the heat absorber composed of the straight section 4 of the shell and the cone section 7 of the shell. The rear end of the cone section 7 of the shell is tightly connected with the exhaust pipe 14. The air pipe 13 is provided with a front end cover 3 at the front end, and a cavity is jointly formed by the front end plate 3 , the shell straight section 4 , and the shell cone section 7 , and the shell cone section 7 is connected with the exhaust pipe 14 .

[0048] A lighting port 2 is opened in the middle of the front end plate 3 , and the daylighting port 2 is covered by a glass cover plate 9 , and the pressure ring 10 fastened to the inside of the front end plate 3 is pressed against the glass cover plate 9 .

[0049] Such as figure 1 and figure 2 As shown, the inner side of the straight section 4 of the housing is provided with a porou...

Embodiment 2

[0052] Such as Figure 6 and Figure 7 As shown, the difference from Embodiment 1 is that at least one cooling air duct 24 is provided on the outside of the front end plate 3, and the external cooling air flow 25 flowing in the cooling air duct 24 can be introduced from the upstream cold air inlet. 13 or the cold air 12 of annular flow passage 18, also can be that extra air pump provides cold air. The outlet of the cooling air duct 24 is provided with a nozzle 27 , and the outlet of the nozzle 27 is located at the edge of the lighting opening 2 . One of the outlet shapes of the nozzle 27 is as Figure 8 As shown, it is designed in a flat shape, with several guide vanes 26 built in, so that the cooling air flow ejected from it is close to the outer wall surface of the glass cover plate 9 and at the same time satisfies the designed flow field distribution characteristics. The role of this part of the cooling air flow is: on the one hand, it plays a role in cooling the glass c...

Embodiment 3

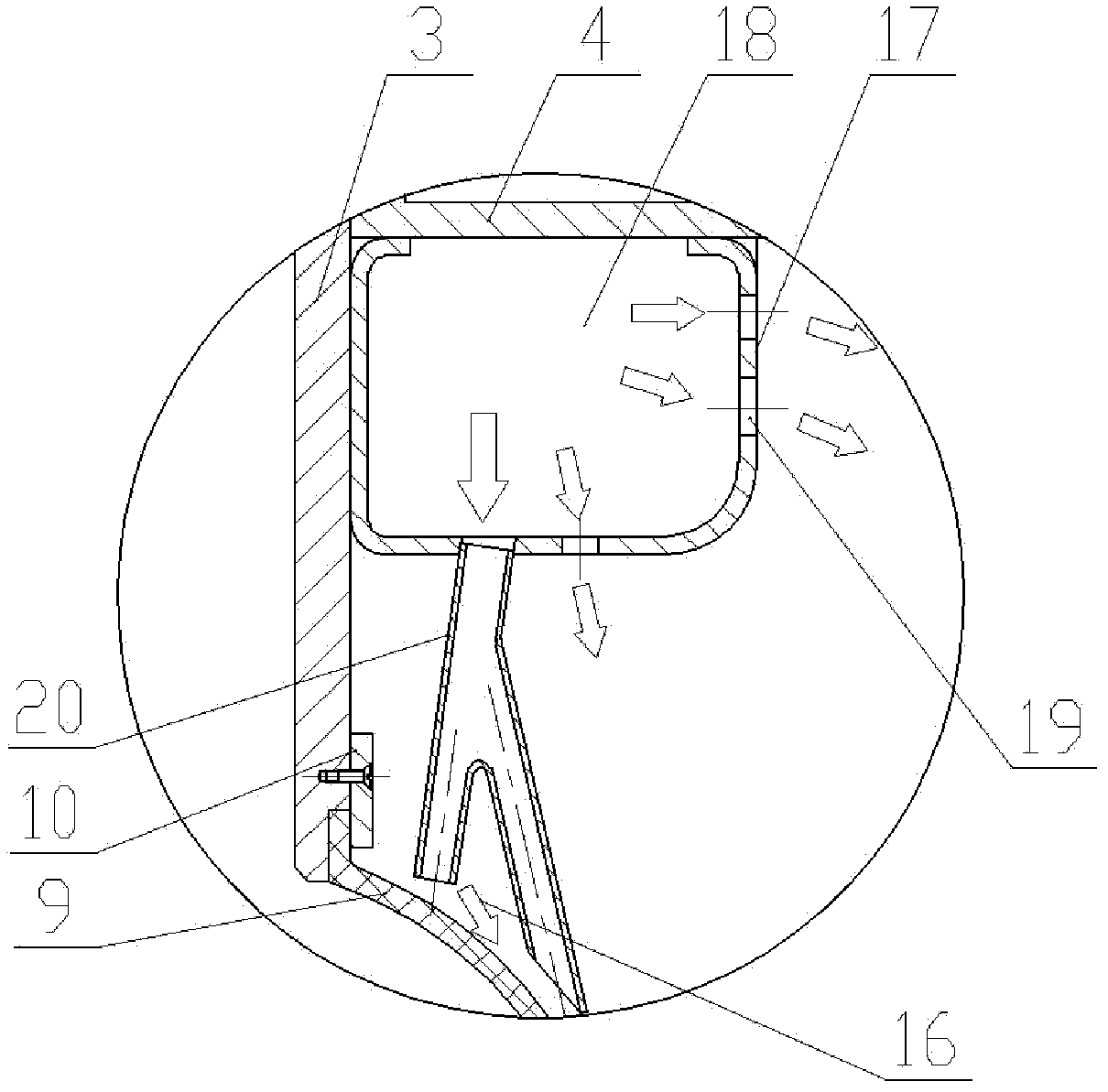

[0054] Such as Figure 9 and Figure 10 As shown, the differences between this embodiment and Embodiment 1 are: 1. The porous wall 17 is canceled, and a cold air jacket 28 is arranged on the front side of the front end plate 3, and the cold air jacket 28 and the front end plate 3 form an annular space 31 , the annular space surrounded by the cold air jacket 28 and the front end plate 3 replaces the annular flow channel 18, the air inlet pipe 13 is connected to the cold air jacket 28, and at least one row of air inlet holes 29 is opened on the front end plate 3, The heat collecting cavity 15 communicates with the annular space 31 through the air inlet 29; 2. On the front end plate 3, several guide tubes 30 passing through the front end plate 3 are arranged, and the outlet of the guide tube 30 is also located on the glass cover plate Near the inner wall of 9, one or several holes can be opened on the side of the guide tube 30 facing the glass cover plate 9, so as to organize th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com