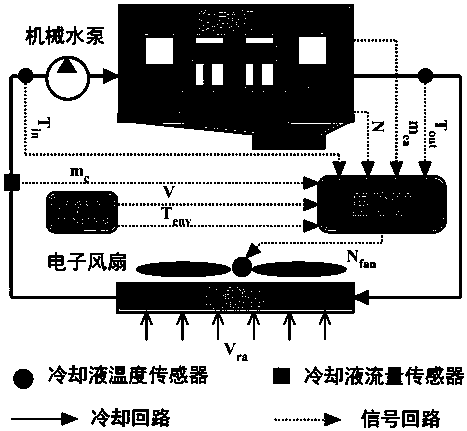

Automobile engine thermal management system modeling and control method

A technology of thermal management system and automobile engine, applied in the direction of cooling of engine components, machine/engine, engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

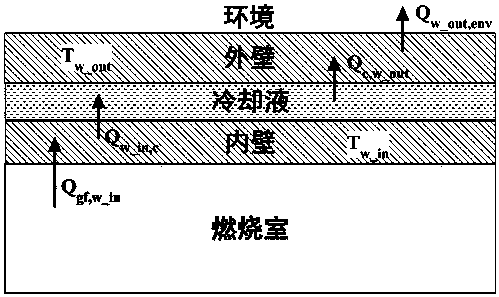

Method used

Image

Examples

Embodiment Construction

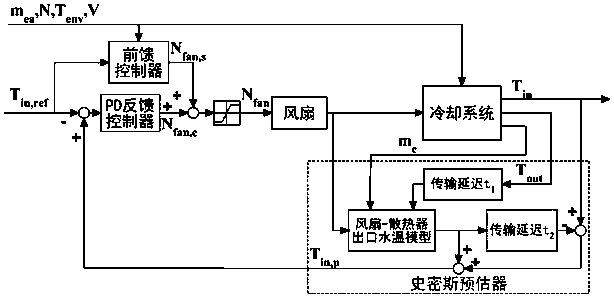

[0197] The control of the engine thermal management system described in the present invention is realized through software co-simulation, and the software adopts Matlab / Simulink and GT-Power. Among them, GT-Power software is a commercial engine one-dimensional simulation software, the main function is to provide a high-fidelity engine thermal management system model, instead of the real engine thermal management system as the controlled object. MATLAB / Simulink software is used to build the controller and observer.

[0198] Functionally, the present invention includes the following parts: an inverse dynamics feed-forward controller module, a Smith predictor module, a PD feedback controller module, and an engine thermal management system module. The role of each part is explained in detail below:

[0199] The inverse dynamics feed-forward controller module calculates the fan speed to achieve the target coolant temperature according to the current measurement signal as the feed-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com