Method for online estimation of IGBT element junction temperature

A component and finite element technology, applied in the field of IGBT temperature detection, can solve the problems of long response time, difficulty in obtaining thermal coupling parameters, increasing stray capacitance parameters, etc., and achieve the effect of high accuracy and fast prediction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

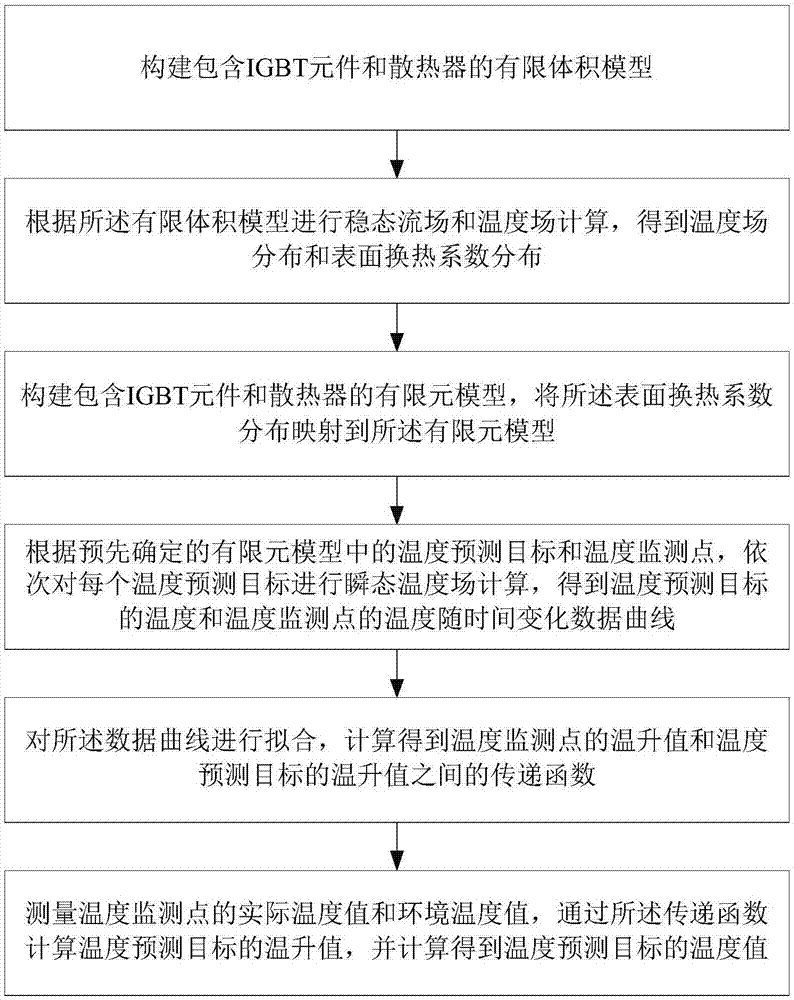

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

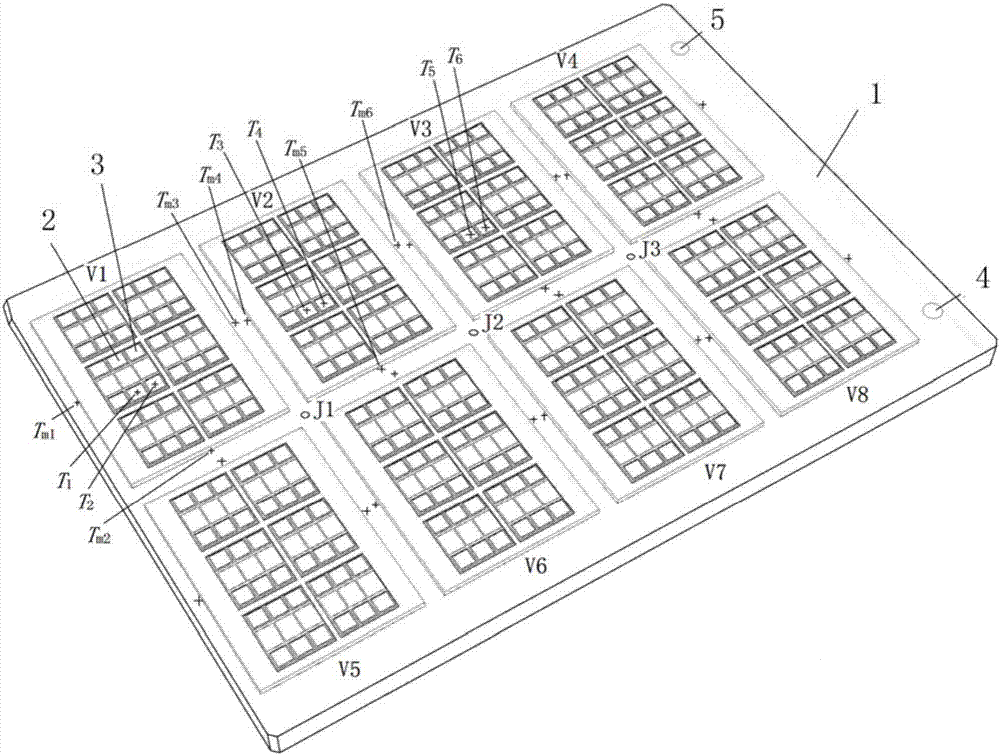

[0039]In practical applications, IGBT devices are usually multiple IGBT components installed on a radiator, and form a converter module with drive circuits, protection circuits, capacitors, sensors, and busbars. According to the functional requirements of the converter module, such as inverter, four-quadrant rectification, chopping, etc., the number of IGBT components is generally 4, 6 or 8. The cooling methods used mainly include forced air cooling, water cooling, and heat pipe cooling. According to Newton’s cooling formula, these cooling methods are reflected on the radiator by the difference in the distribution of surface heat transfer coefficients (also known as convective heat transfer coefficients), such as water cooling methods. The surface heat transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com