Method for determining interface heat exchange coefficient of large-sized steel ingot

A technology of interface heat transfer coefficient and steel ingot, applied in the direction of material thermal conductivity, material thermal development, etc., can solve the problems of difficult determination of interface heat transfer coefficient and large error of calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

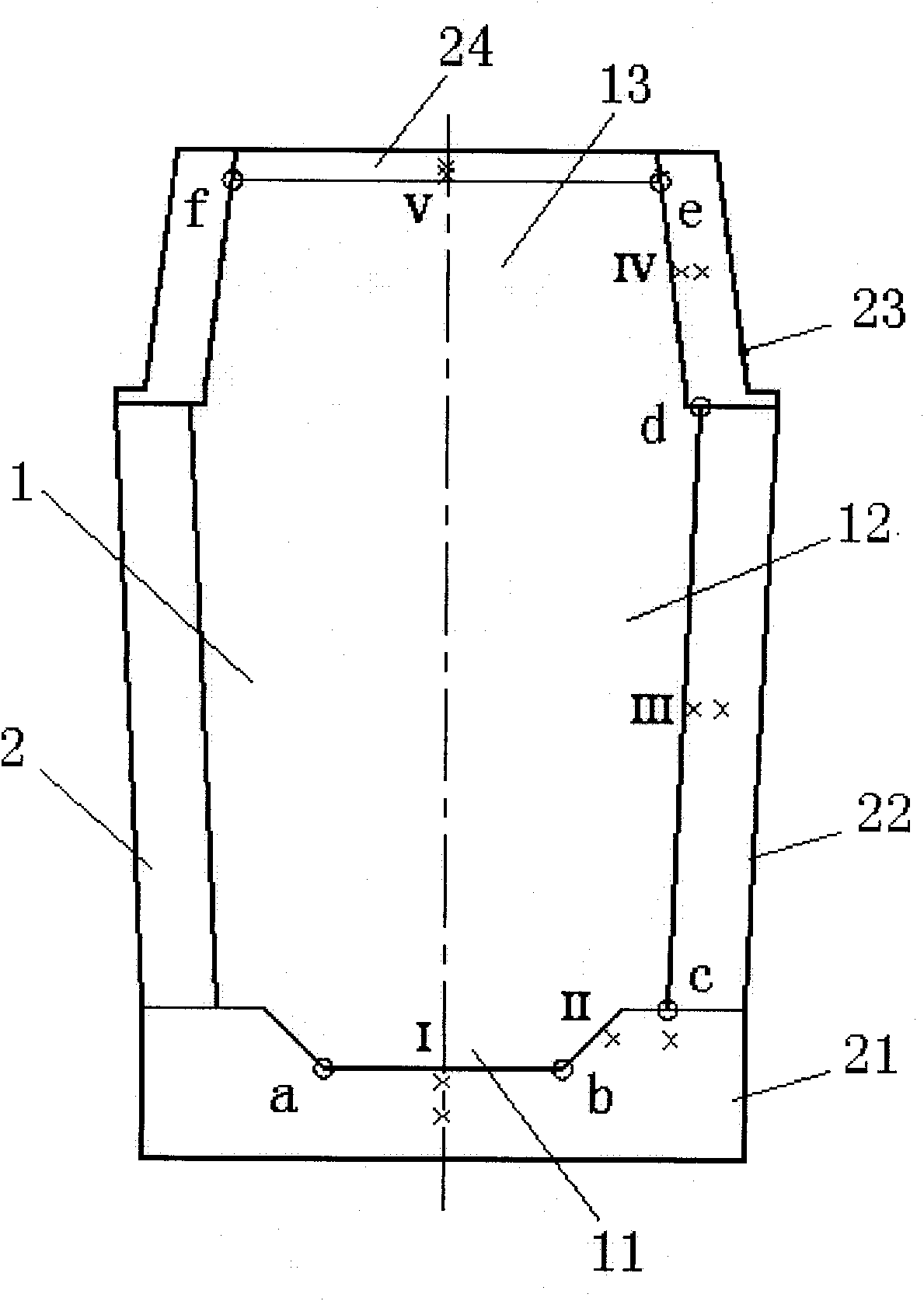

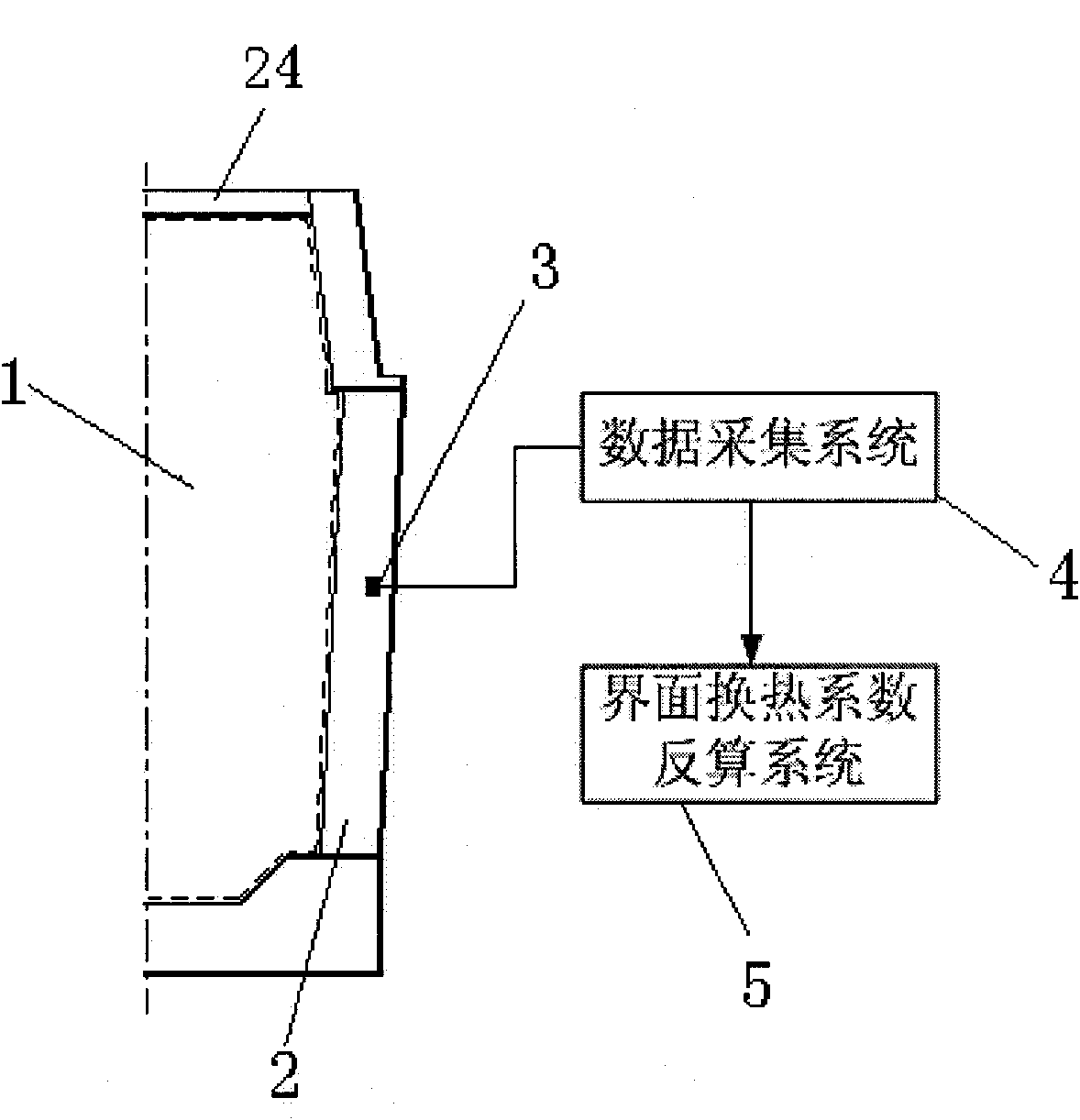

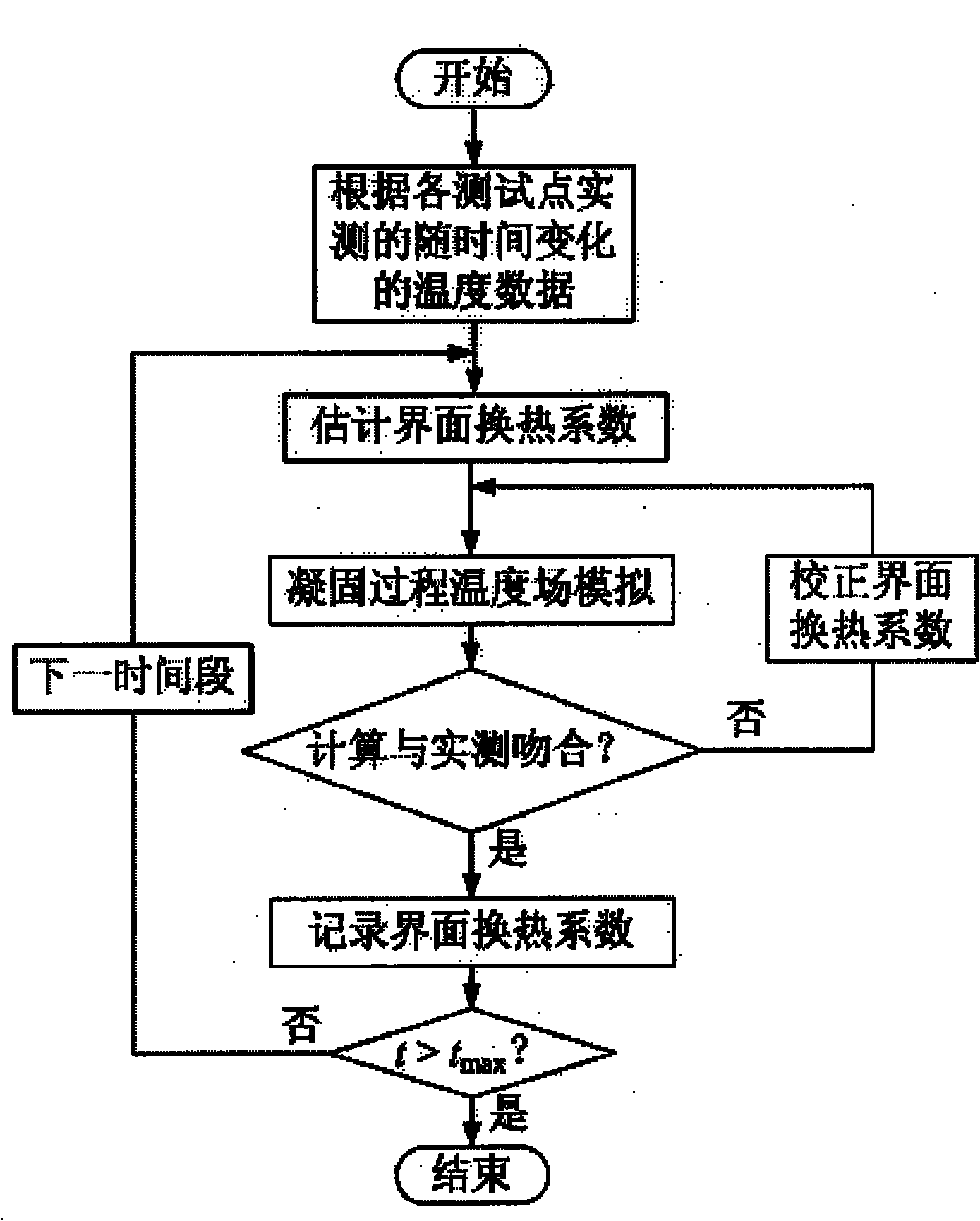

[0026] The present invention is to determine the heat transfer coefficient of the contact interface between the steel ingot 1 and the ingot mold 2 . Such as figure 1 As shown, the steel ingot 1 of the present invention includes an ingot tail 11 , an ingot body 12 and a riser 13 . The ingot mold 2 of the present invention includes a chassis 21 , a mold body 22 , a riser sleeve 23 and a heating agent 24 , and the heating agent 24 is poured on the top surface of the riser 13 . Since the inner side of the contact interface between steel ingot 1 and ingot mold 2 is molten steel or solidified shell, the test is difficult and the test cost is high; while the outer side of the contact interface between steel ingot 1 and ingot mold 2 is ingot mold 2, and the test is relatively simple , Therefore, the present invention determines the heat transfer coefficient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com